Wall flow type particle filter carrier coating method adopting organic sol

A particle filter and organosol technology, applied in chemical instruments and methods, separation methods, coatings, etc., can solve problems such as limited cost, catalyst coating difficulties, catalyst structure, atomic ratio and adverse effects of catalytic effects, etc. achieve the effect of promoting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

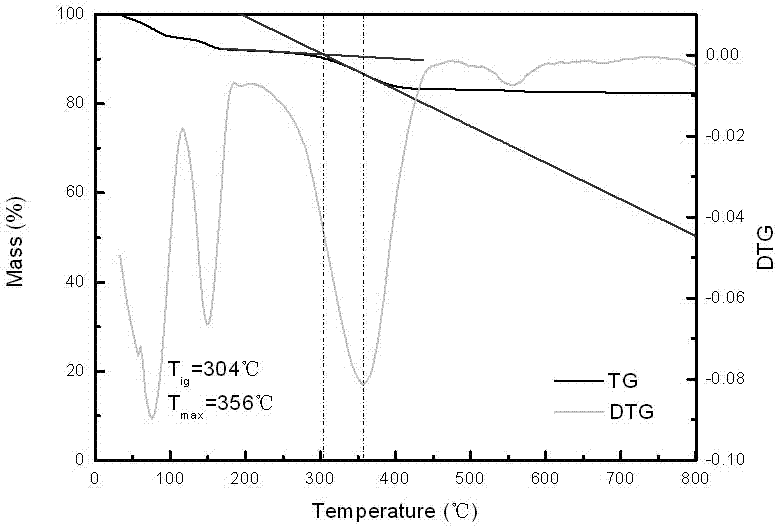

[0022] Embodiment 1 (comparative example)

[0023] A 200-mesh cordierite wall-flow particle filter was selected as the test object, and processed in the following order:

[0024] A) Put the wall-flow particle filter in the alumina sol with a solid content of 6% for 2 hours, take it out, drain the excess alumina sol in the DPF carrier channel, and bake it at 400°C for 2 hours to form α-Al2O3 coating covered Wall flow particulate filter.

[0025] B) The catalyst is a potassium-containing perovskite catalyst La 0.9 K 0.1 FeO 3 (The molar ratio of potassium element in the catalyst metal is 5%). The particle size of the catalyst is controlled below 3 μm by ball milling. Surfactant PVP and stirring are used to promote the dispersion of the catalyst. The solid content of the catalyst is 4%.

[0026] C) Immerse the α-Al2O3 coated wall-flow particle filter obtained in step A) into the suspension obtained in step B) and keep it for 1 hour; take it out, and use compressed air to blow...

Embodiment 2

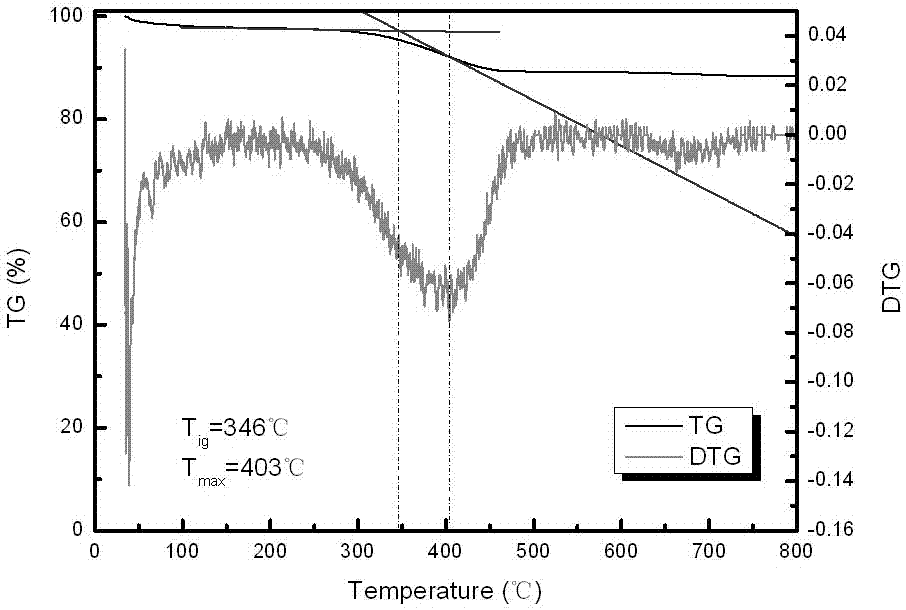

[0030] A 200-mesh cordierite wall-flow particle filter was selected as the test object, and processed in the following order:

[0031] A) Put the wall-flow particle filter in the alumina sol with a solid content of 6% for 2 hours, take it out, drain the excess alumina sol in the DPF carrier channel, and bake it at 400°C for 2 hours to form α-Al2O3 coating covered Wall flow particulate filter.

[0032] B) Preparation of potassium-containing perovskite catalyst La 0.9 K 0.1 FeO 3 (The molar ratio of potassium element in the catalyst metal is 5%) suspension, the first component adopts 2-butanone, and the second component is the selected catalyst, La 0.9 K 0.1 FeO 3 , the third component uses the polymer shown in (I) (m=100, n=20, R 1 =R 2 =H, x=y=2), the mass ratio of the three is 88:12:0.6, and the particle size of the catalyst is controlled below 3 μm by ball milling.

[0033]C) Immerse the α-Al2O3 coated wall-flow particle filter obtained in step A) into the suspension...

Embodiment 3

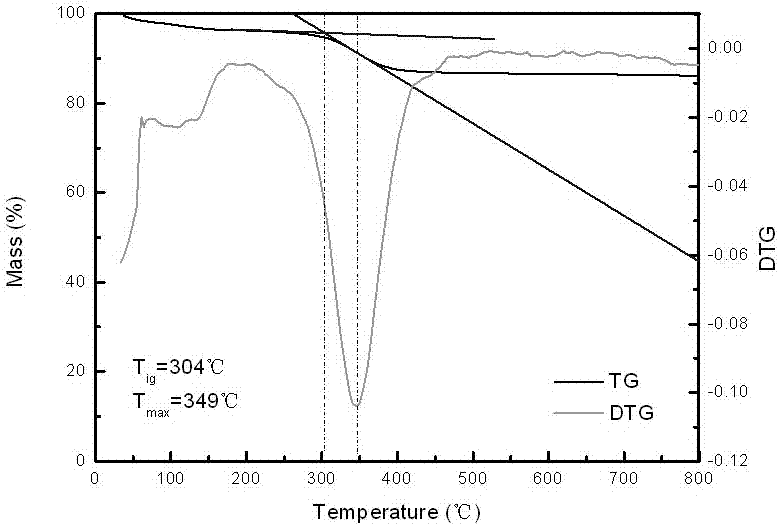

[0037] A 200-mesh cordierite wall-flow particle filter was selected as the test object, and processed in the following order:

[0038] A) Put the wall-flow particle filter in the alumina sol with a solid content of 6% for 2 hours, take it out, drain the excess alumina sol in the DPF carrier channel, and bake it at 400°C for 2 hours to form α-Al2O3 coating covered Wall flow particulate filter.

[0039] B) Preparation of potassium-containing perovskite catalyst La 0.6 K 0.4 FeO 3 (The molar ratio of potassium element in the catalyst metal is 20%) suspension, the first component adopts xylene, the second component is the selected catalyst, La 0.6 K 0.4 FeO 3 , the third component uses the polymer shown in (I) (m=1000, n=200, R 1 =R 2 =CH 3 , x=y=10), the mass ratio of the three is 96:4:0.04, and the particle size of the catalyst is controlled below 3 μm by ball milling.

[0040] C) Immerse the α-Al2O3 coated wall-flow particle filter obtained in step A) into the suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com