Fuzzy neural network decoupling controller for bearing-free permanent magnet synchronous motor

A technology of fuzzy neural network and permanent magnet synchronous motor, applied in the field of decoupling controller, achieves the effect of simple inverse system structure, reduced control cost, and simple and clear mathematical analysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

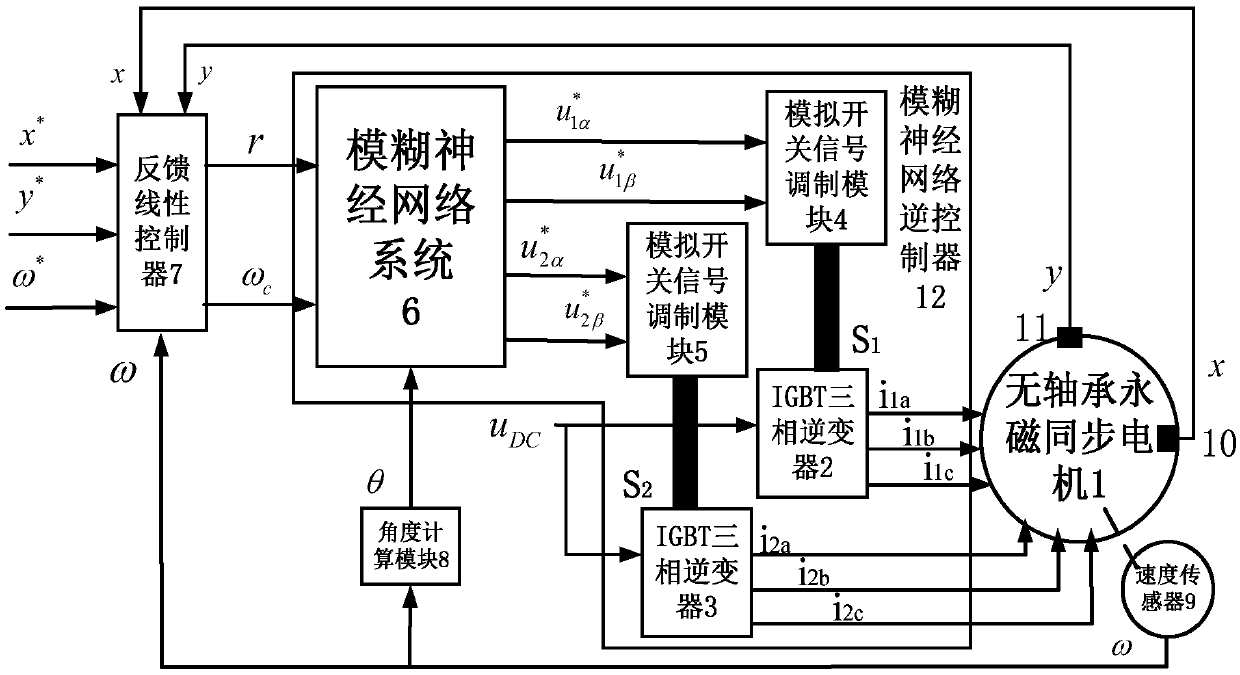

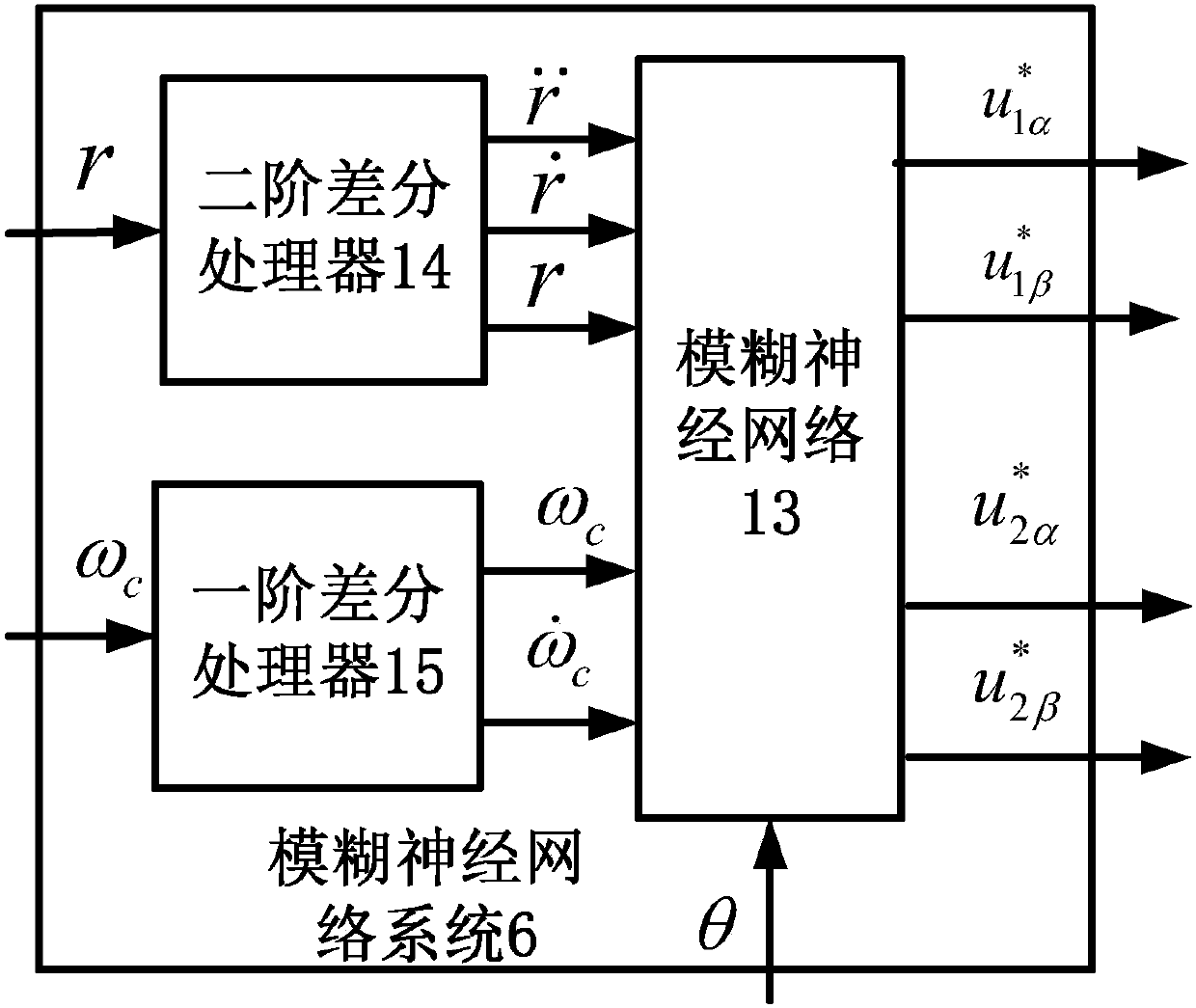

[0016] see figure 1 and figure 2 , the present invention is composed of a feedback linear controller 7 and a fuzzy neural network inverse controller 12, the feedback linear controller 7 is connected in series with the fuzzy neural network inverse controller 12, and the fuzzy neural network inverse controller 12 is connected in series with a bearingless permanent magnet synchronous motor 1 , used to control the bearingless permanent magnet synchronous motor 1 .

[0017] The mathematical model of the bearingless permanent magnet synchronous motor 1 is a 5th order differential matrix equation, and its relative vector order is {2,2,1}. Can be verified by the Interactor algorithm. The bearingless permanent magnet synchronous motor 1 is reversible, that is, the right inverse system exists, and the right inverse system is constructed with reference to the structure of the neural network, and the fuzzy neural network inverse controller 12 is constructed according to this method.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com