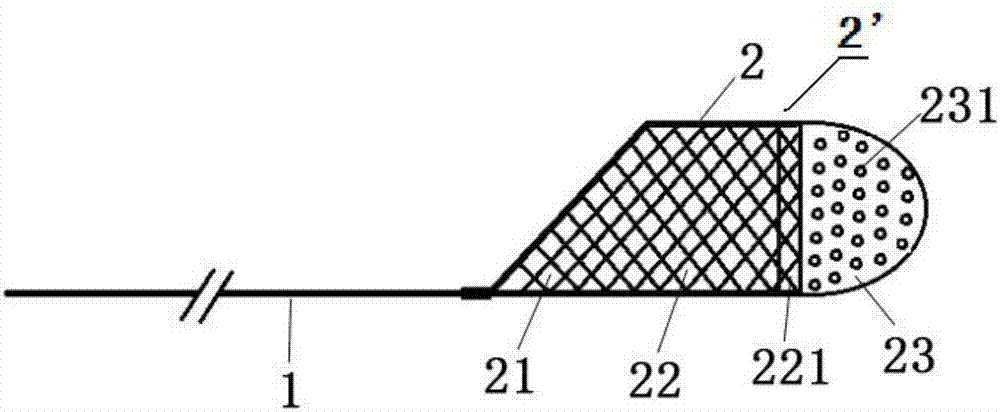

Cerebral vessel distal-end protector and film coating method for same

A protector and cerebrovascular technology, applied in the field of medical devices, can solve the problems of blocking blood flow, scratching blood vessel walls, structural fractures, etc., and achieve the effect of ensuring stable blood flow, ensuring distal blood flow, and less vascular stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The mesh diameter on the metal mesh basket body is 400 μm.

[0077] (1) Add TECOFLEX series aliphatic polyurethane to dichloromethane, when TECOFLEX series aliphatic polyurethane is completely and evenly dissolved in dichloromethane to form a pre-coating solution; the mass volume ratio of TECOFLEX series aliphatic polyurethane to dichloromethane is 0.005g / mL;

[0078] (2) The pre-coating solution in the step (1) is degassed by ultrasonic waves under nitrogen conditions, the frequency of the ultrasonic wave is 80KHz, the temperature of the degassed treatment is 25°C, and the time is 5h; The pre-coating solution is filtered by a microporous filter membrane with a pore size of 0.5um, and the filtrate is the coating solution;

[0079] (3) Dip-coat the coating solution in step (2) on the entire distal end of the wire mesh basket body by dip-coating method under nitrogen gas, and dry at 25°C for 10 min under nitrogen gas for each dip-coating. After dipping and drying for t...

Embodiment 2

[0084] The mesh diameter on the metal mesh basket body is 400 μm.

[0085] (1) Add TECOFLEX series aliphatic polyurethane to ethanol, when TECOFLEX series aliphatic polyurethane is completely and evenly dissolved in ethanol to form a precoat solution; TECOFLEX series aliphatic polyurethane and ethanol are 0.05g / mL;

[0086] (2) The pre-coating solution in the step (1) is degassed by ultrasonic waves under nitrogen conditions, the frequency of the ultrasonic waves is 50KHz, the temperature of the degassed treatment is 40°C, and the time is 10h; the degassed The pre-coating solution is filtered by a microporous filter membrane with a pore size of 0.2um, and the filtrate is the coating solution;

[0087] (3) Under nitrogen conditions, adopt the dip coating method to dip-coat the coating solution in step (2) on the entire far end of the metal mesh basket body and the part of the middle section connected to the far end. Dry at 35°C for 30 minutes under the same conditions, dip-coa...

Embodiment 3

[0092] The mesh diameter on the metal mesh basket body is 500 μm.

[0093] (1) Add Pellethane2363 series 80AE aromatic polyurethane to acetone, and when Pellethane2363 series 80AE aromatic polyurethane is completely and uniformly dissolved in acetone, a precoat solution is formed; the mass-volume ratio of Pellethane2363 series 80AE aromatic polyurethane to acetone is 0.001g / mL;

[0094] (2) The pre-coating liquid in the step (1) is first degassed by ultrasonic waves under nitrogen conditions, the frequency of the ultrasonic wave is 130KHz, the temperature of the degassed treatment is 0°C, and the time is 2h; The pre-coating solution is filtered by a microporous filter membrane with a pore size of 0.8um, and the filtrate is the coating solution;

[0095] (3) Dip-coat the coating solution in step (2) on the entire distal end of the wire mesh basket body by dip-coating under nitrogen, and dry it at 25°C for 5 minutes under nitrogen for each dip-coating. After dipping and drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com