Preparation method of chitosan-soybean protein composite porous microspheres for lead adsorption

A technology of soybean protein and porous microspheres, which is applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems that have not been studied in the past, simplify the operation process, and improve lead adsorption Efficiency, the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

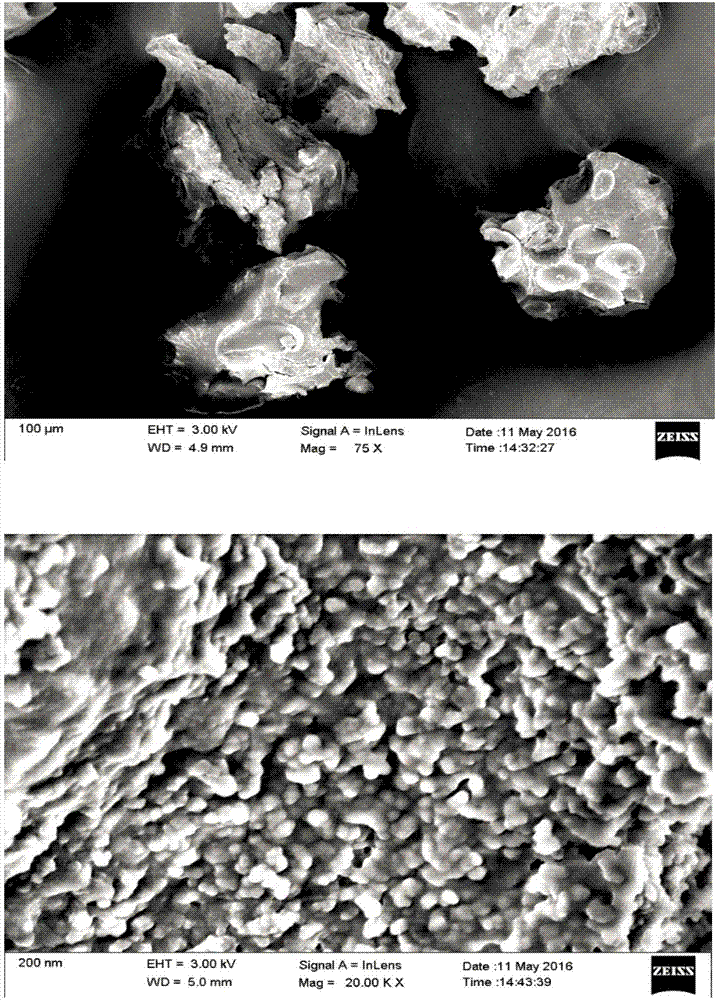

Image

Examples

Embodiment Construction

[0023] (1) Preparation of chitosan-soybean protein composite porous microspheres:

[0024] Weigh 4g of chitosan in a 100mL beaker, add 50mL of acetic acid solution with a concentration of 2% by mass, stir and dissolve, then let stand for 12 hours, remove air bubbles in the solution to obtain a chitosan solution, and set aside. Add 2.0g of soybean protein and 40mL of secondary water into a 100mL beaker, stir until completely dissolved to obtain a soybean protein solution, and set aside; mix 40mL of the above-mentioned chitosan solution with 40mL of the above-mentioned soybean protein solution, and add 2.0g of nano-silica, Stir evenly to obtain chitosan-soybean protein-silicon dioxide mixed liquid, set aside.

[0025] Take 140mL of liquid paraffin in a 250mL three-necked flask, add dropwise 4 drops of analytically pure active agent Span 80, mechanically stir (300r / min) for 30 minutes, heat the water bath to 60°C, and mix 60mL of chitosan-soybean protein-silica Add the mixed sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com