Method for preparing metal structure on transparent material surface by using metal nano-ink

A metal nano and metal structure technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of large loss of raw materials, complex preparation process, low production efficiency, etc., to reduce energy consumption, simplify the preparation process, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

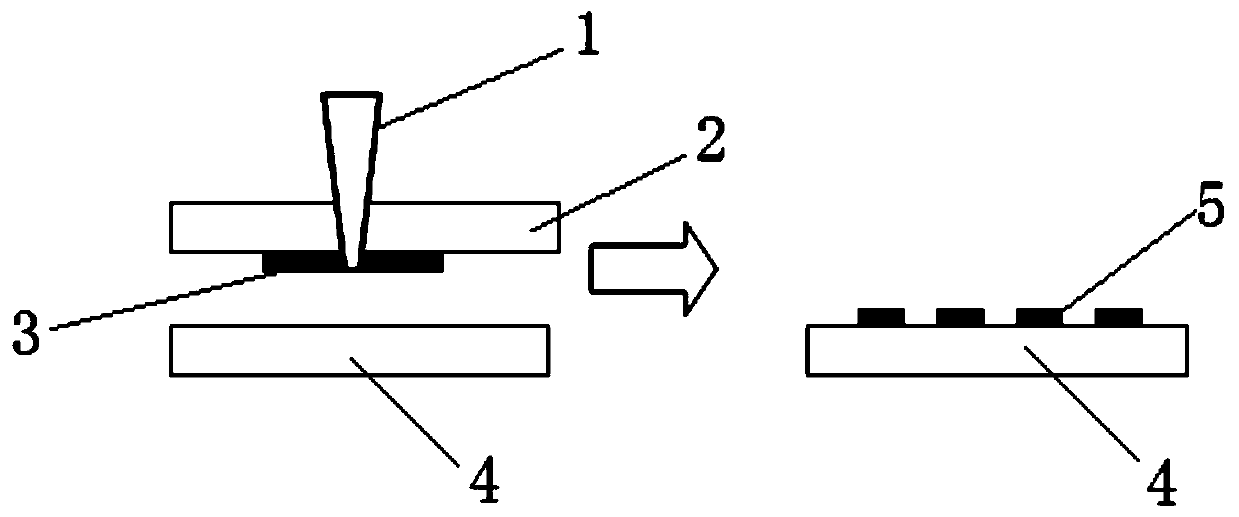

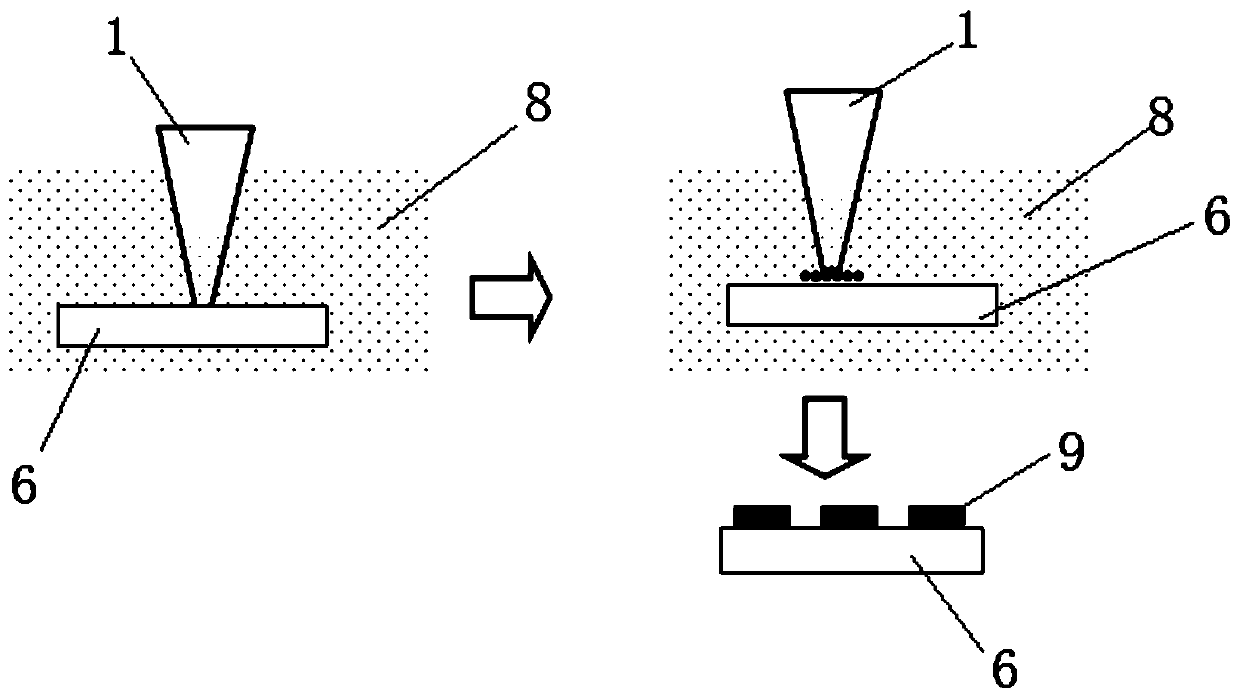

[0031] This embodiment provides a method of using metal nano-ink to prepare a metal structure on the surface of a transparent material, such as image 3 As shown, the method includes the following steps:

[0032] a. Take the metal nano-ink 8, the solute of the metal nano-ink 8 is metal silver nanoparticles, the solvent is an alcoholic organic solvent, ethanol in this embodiment, and the mass concentration of the metal nano-ink is 70%.

[0033] b. Take the transparent substrate 6, which is a low melting point transparent polymer substrate, place it in the metal nano-ink 8, and immerse the metal nano-ink 8 into the transparent substrate 6;

[0034] c. Set the laser processing parameters and focus position so that the laser beam 1 penetrates the metal nano-ink 8 on the top of the transparent substrate 6 and irradiates the top surface of the transparent substrate 6. The laser described in this embodiment is a short-pulse laser with a wavelength of 355nm , with a power of 0.1W and...

Embodiment 2

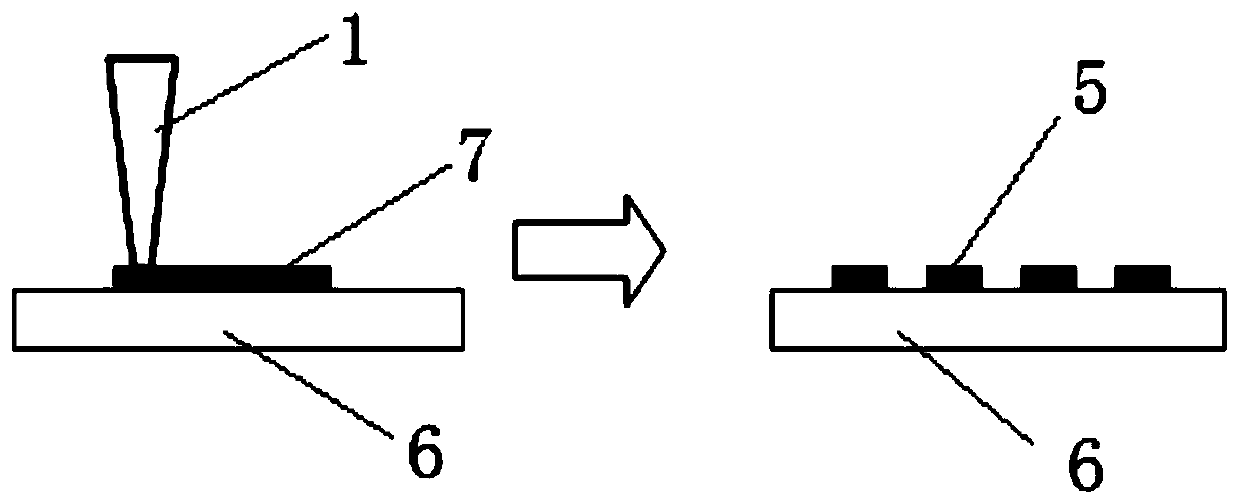

[0038] This embodiment provides a method of using metal nano-ink to prepare a metal structure on the surface of a transparent material, such as Figure 4 As shown, the method includes the following steps:

[0039] a. Take the metal nano-ink 8, the solute of the metal nano-ink 8 is magnesium alloy nanoparticles, the solvent is water, and the mass concentration of the metal nano-ink 8 is 50%;

[0040] b. Take the transparent substrate 6, which is a glass substrate, place it in the metal nano-ink 8, and make the transparent substrate 6 float on the surface of the metal nano-ink 8;

[0041] c. Set the laser processing parameters and focus position so that the laser beam 1 penetrates the transparent substrate 6 and irradiates the bottom surface of the transparent substrate 6. The power of the laser is 1W, and the frequency is 1MHz. In this embodiment, the laser is Ultrashort pulse laser with a wavelength of 532nm;

[0042] d. The metal nano-ink 8 is analyzed and selectively sinte...

Embodiment 3

[0045] This embodiment provides a method of using metal nano-ink to prepare a metal structure on the surface of a transparent material, such as Figure 4 As shown, the method includes the following steps:

[0046]a. Get the metal nano-ink 8, the solute of the metal nano-ink 8 is metal aluminum nanoparticles, the solvent is an alcoholic organic solution, which is ethylene glycol in this embodiment, and the concentration of the metal nano-ink 8 is 15%;

[0047] b. Take the transparent substrate 6, which is a sapphire substrate, place it in the metal nano-ink 8, and make the metal nano-ink 8 immerse the transparent substrate 6;

[0048] c. Set the laser processing parameters and focus position so that the laser beam 1 penetrates the metal ink above the transparent substrate 6 and irradiates the upper surface of the transparent substrate 6. The laser described in this embodiment is a continuous laser with a wavelength of 1064nm, and its power 5W, frequency 500Hz;

[0049] d. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com