Water inlet device and water inlet method for anaerobic reactor

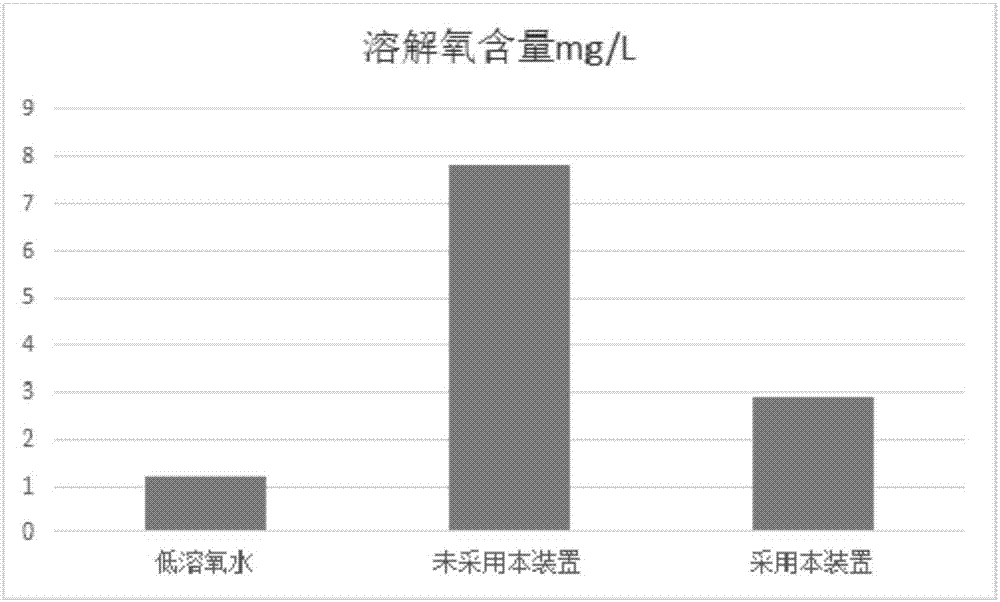

An anaerobic reactor and water inlet device technology, applied in chemical instruments and methods, biological treatment adjustment methods, anaerobic digestion treatment, etc., can solve the problems of limited engineering application, long doubling time, low cell yield, etc. , to achieve the effects of convenient gas production control, fast gas production response, and simple design subject

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

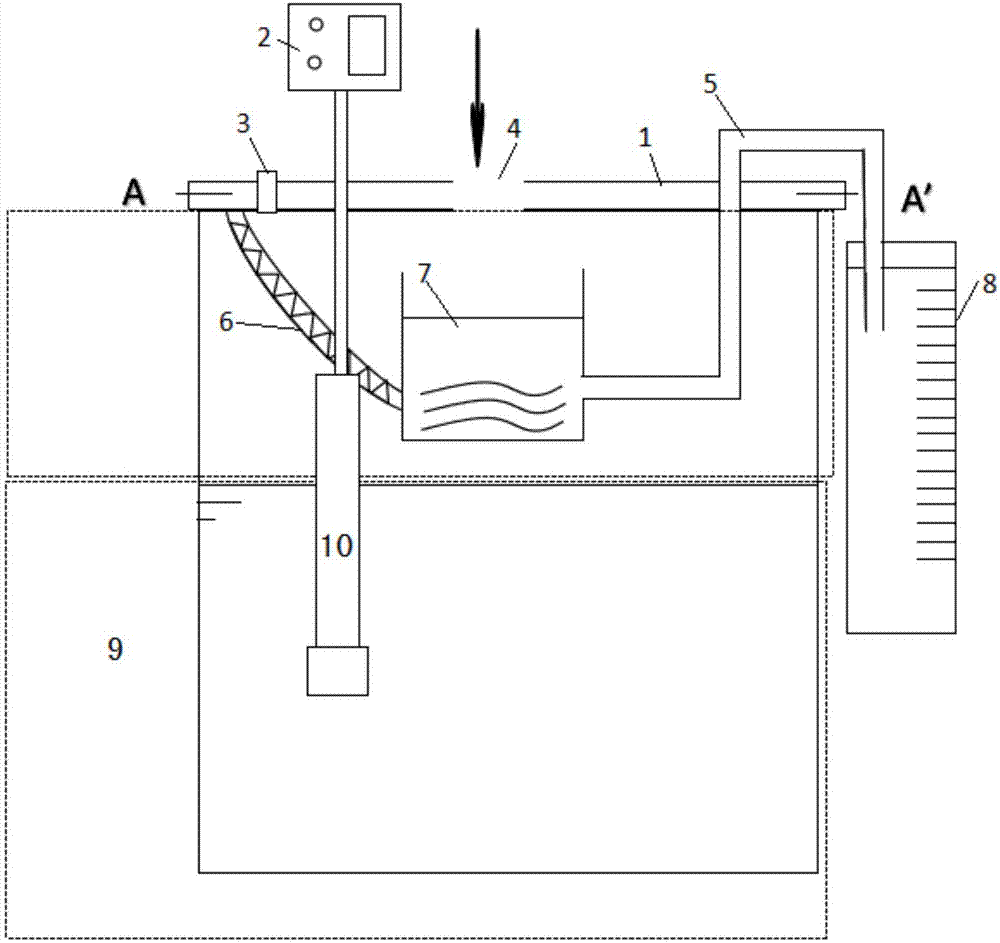

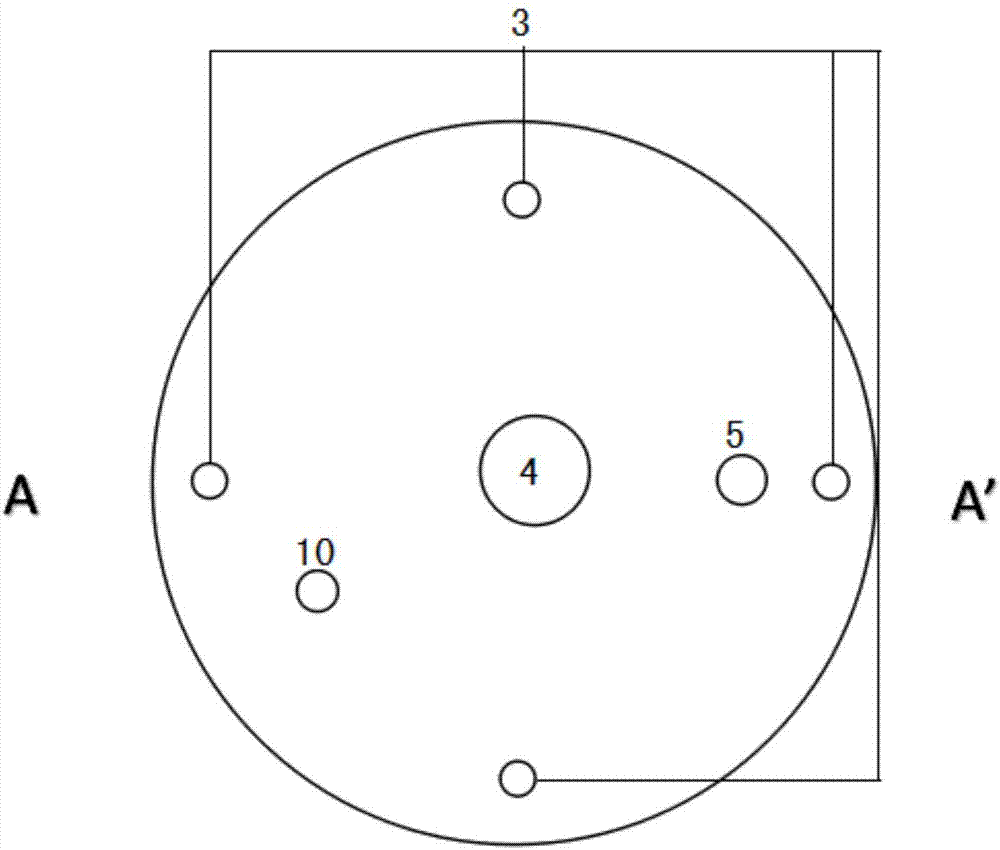

[0032] see figure 1 , the device in this embodiment includes a water inlet bucket, a water inlet bucket cover, a gas producing body and a dissolved oxygen measuring device; low dissolved oxygen water is housed in the water inlet bucket, and the water inlet bucket cover is covered on the top of the water inlet bucket and is provided with an air outlet and is used for inputting solid materials The gas-generating body is located in the water inlet bucket, and is suspended above the liquid level of the low-dissolved oxygen water in the water-intake bucket. The gas-generating body includes a gas-generating container and a liquid supply device for supplying liquid materials. The gas-generating container is set It is directly below the feed port of the water inlet barrel and is suspended above the liquid level in the water inlet barrel through a connecting piece; the liquid supply device is arranged outside the water inlet barrel and connected to the gas production container, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com