Preparation method of loss-control fertilizer taking rice straws as raw material

A technology for rice straw and fertilizer loss control, applied in the field of fertilizer loss control, can solve problems such as high price and environmental risks, and achieve the effects of controlling loss, improving crop quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Pretreatment of rice straw to prepare rice straw powder: the rice straw is naturally air-dried and then cut by a cutting machine. The length of the processed rice straw raw material is less than 3cm, and the moisture content is controlled at less than 15%. Wash it with distilled water, boil it in boiling water for 3 hours, and dry it in an oven. Pulverize with a universal pulverizer to obtain straw powder with a particle size of less than 180 μm;

[0021] (2) Preparation of rice straw lignin and cellulose: Weigh the rice straw powder prepared in step (1), add it to a clean Erlenmeyer flask, then slowly add acetic acid-ethanol mixed organic solvent to the Erlenmeyer flask, the rice straw The solid-to-liquid mass ratio of powder and acetic acid-ethanol mixed organic solvent is 1:2. After soaking for 50 minutes, heat to 95°C with a heating mantle and react for 3.5 hours. After the reaction is completed and cooled to room temperature, the Erlenmeyer flask and the filte...

Embodiment 2

[0028](1) Pretreatment of rice straw to prepare rice straw powder: the rice straw is naturally air-dried and then cut by a cutting machine. The length of the processed rice straw raw material is less than 3cm, and the moisture content is controlled at less than 15%. Wash it with distilled water, boil it in boiling water for 4 hours, and dry it in an oven. Pulverize with a universal pulverizer to obtain straw powder with a particle size of less than 180 μm;

[0029] (2) Preparation of rice straw lignin and cellulose: Weigh the rice straw powder prepared in step (1), add it to a clean Erlenmeyer flask, then slowly add acetic acid-ethanol mixed organic solvent to the Erlenmeyer flask, the rice straw The solid-to-liquid mass ratio of powder and acetic acid-ethanol mixed organic solvent is 1:3. After soaking for 60 minutes, heat to 95°C with a heating mantle and react for 3 hours. After the reaction is completed and cooled to room temperature, the Erlenmeyer flask and the filter r...

Embodiment 3

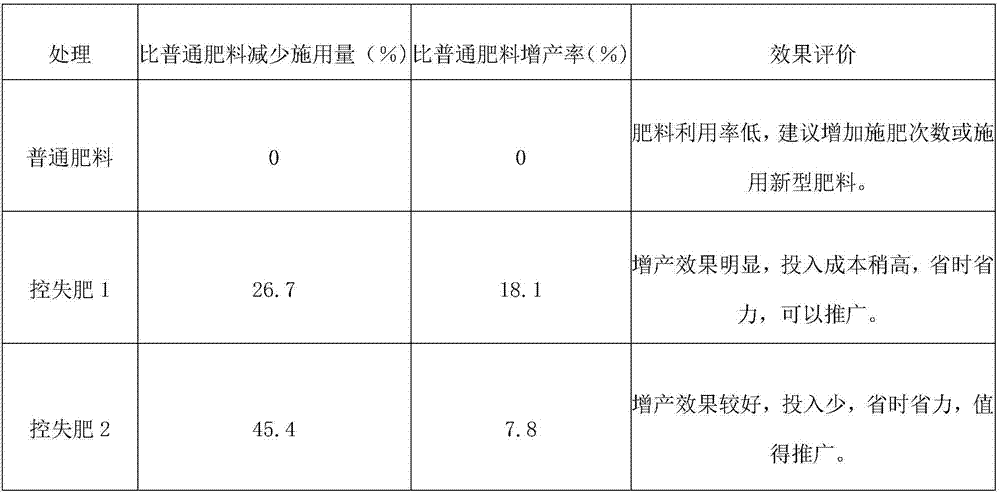

[0036] (1) Field experiment design

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com