Automobile protective device material and preparation process thereof

A protection device and a preparation process technology, which are applied in the field of automobile protection device materials and the preparation process thereof, can solve the problems that it is difficult to meet the requirements of recycling standards and the protection performance is difficult to meet the protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

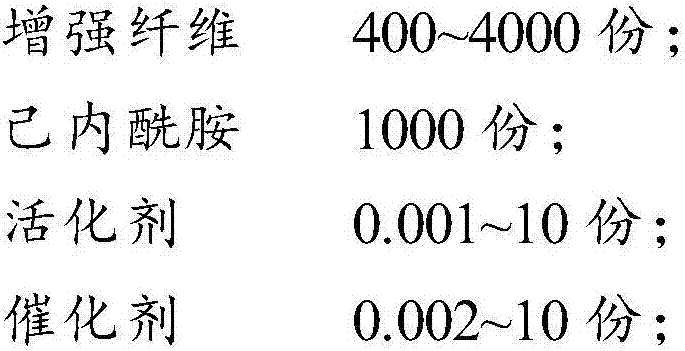

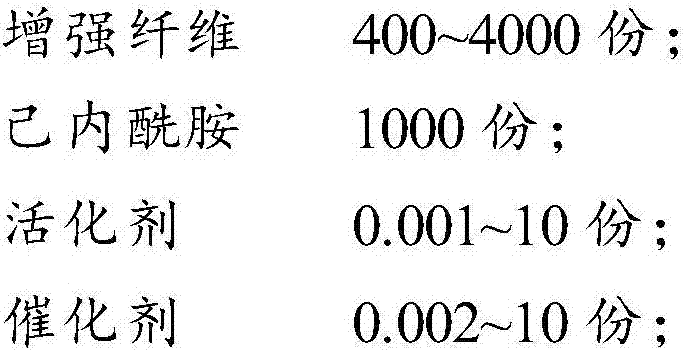

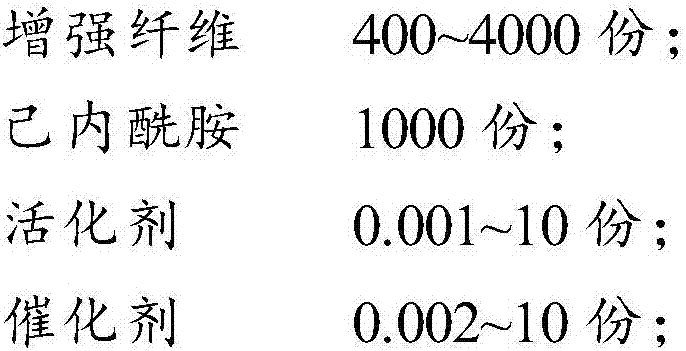

Method used

Image

Examples

Embodiment 1

[0046] 1.1 Product preparation

[0047] 1000g of caprolactam was vacuum dehydrated at 120°C, and the mass ratio of dehydration to caprolactam was controlled to be 200ppm to obtain a dehydrated product; then 5g of HDI and 5g of sodium hydroxide were added to mix, and the temperature was raised to 150°C to obtain a melt with a viscosity of about 0.05pa.s Active material: Lay the glass fiber fabric in the mold, inject the active material into the mold under the injection pressure of 2MPa, fully impregnate the glass fiber at 150°C and polymerize and solidify to obtain a glass fiber reinforced nylon composite beam.

[0048] 1.2 Mechanical performance test

[0049] The physical and mechanical properties of the obtained composite beam were tested, and the results showed that the tensile strength was greater than 650MPa, the flexural strength was greater than 620MPa, and the flexural modulus was greater than 30GPa.

[0050] 1.3 Protective application test

[0051] The obtained compo...

Embodiment 2

[0055] 1.1 Product preparation

[0056] Vacuum dehydrate 1000g caprolactam at 120°C, control the mass ratio of the dehydration amount to caprolactam to 150ppm, and obtain the dehydrated product; then add 5g MDI and 5g sodium hydroxide to mix, heat up to 180°C, and obtain a melt with a viscosity of about 0.05pa.s Active material: mix and impregnate carbon fiber fabric and active material at 180°C and 3MPa, then pass the carbon fiber impregnated with active material through a mold with a specific cavity at a traction speed of 2m / min, extrude excess material, and the material in the mold Polymerize and solidify to obtain a carbon fiber reinforced nylon composite beam.

[0057] 1.2 Mechanical performance test

[0058] The physical and mechanical properties of the obtained composite beam were tested, and the results showed that the tensile strength was greater than 850MPa, the flexural strength was greater than 1250MPa, and the flexural modulus was greater than 120GPa.

[0059] 1...

Embodiment 3

[0064] 1.1 Product preparation

[0065] Vacuum dehydrate 1000g caprolactam at 120°C, control the mass ratio of dehydration to caprolactam to 200ppm, and obtain the dehydrated product; then add 5g TDI and 5g sodium methoxide to mix, and heat up to 150°C to obtain a melting activity with a viscosity of about 0.05pa.s Materials: Lay the glass fiber fabric in the mold, inject the active material into the mold under the injection pressure of 2MPa, fully impregnate the glass fiber at 150°C and polymerize and solidify to obtain a glass fiber reinforced nylon composite beam.

[0066] 1.2 Mechanical performance test

[0067] The physical and mechanical properties of the obtained composite beam were tested, and the results showed that the tensile strength was greater than 650MPa, the flexural strength was greater than 620MPa, and the flexural modulus was greater than 30GPa.

[0068] 1.3 Protective application test

[0069] The obtained composite beam is installed on the support to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com