Method for preparing two-dimensional metal organic framework material and application thereof

A metal-organic framework and organic molecule technology, applied in the field of preparation of two-dimensional metal-organic framework materials, can solve the problems of unsuitability for industrialization, slow reaction speed, complicated process, etc., and achieve the effects of simple equipment, fast reaction, and simple reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Metal Organic Framework UiO-66-NH 2

[0033] The zirconium tetrachloride of 0.1864g and the 2-aminoterephthalic acid of 0.07246g are dissolved in the DMF of 40mL respectively, add zirconium tetrachloride DMF solution and 10mL acetic acid in the DMF solution of 2-aminoterephthalic acid, After ultrasonic mixing, put it into an oven and react at 120°C for 24h. Centrifuge, wash 3 times with DMF, exchange and activate with methanol, soak for 12h, 2 times in total, wash 3 times with methanol, and dry to get UiO-66-NH 2 .

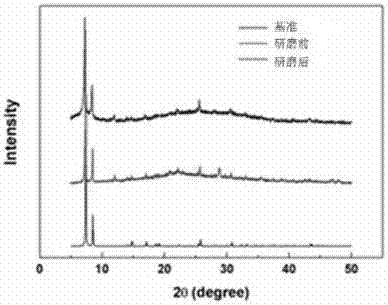

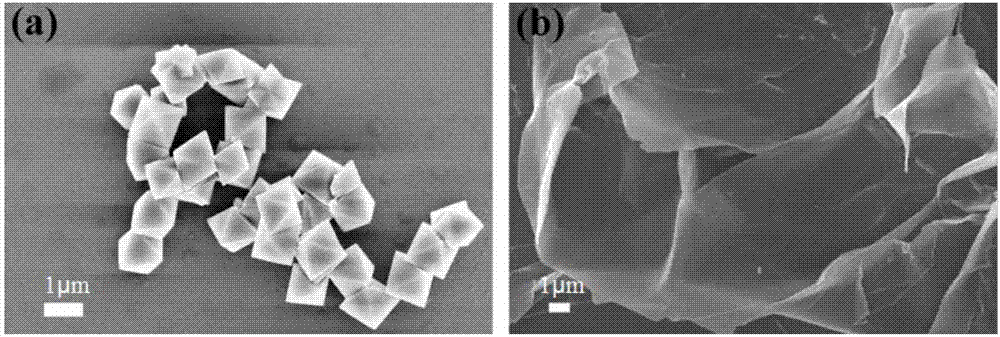

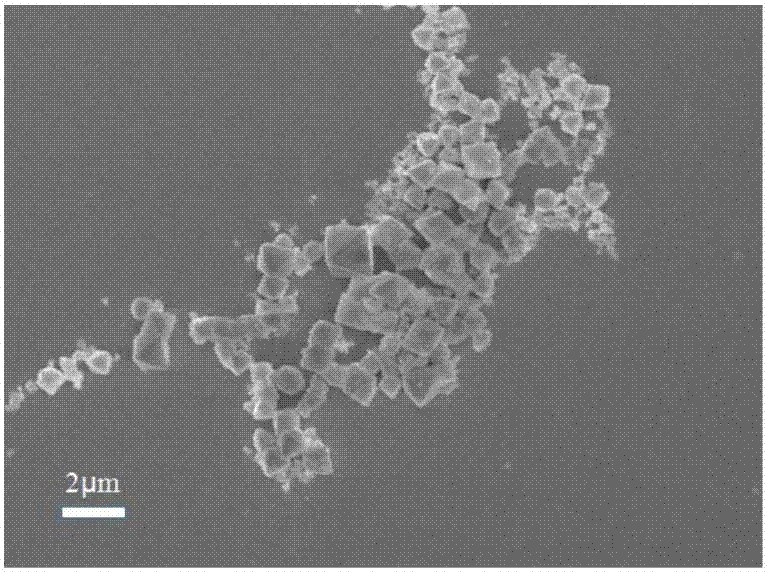

[0034] At room temperature, rhodamine B and UiO-66-NH2 were mixed evenly at a mass ratio of 1:6, ground for 8 minutes, and the resulting product was washed, centrifuged, and dried to obtain two-dimensional MOFs nanosheets. Then carry out XRD to the obtained sample, SEM characterizes, as figure 1 with figure 2 shown.

Embodiment 2-5

[0036] Metal-organic framework material UiO-66-NH was prepared according to the method of Example 1 2

[0037] At room temperature, rhodamine B and UiO-66-NH 2 Mix evenly according to the mass ratio of 1:1, 1:4, 1:5, and 1:11 respectively, grind for 8 minutes, wash, centrifuge, and dry the obtained product to obtain two-dimensional MOFs nanosheets.

Embodiment 6-12

[0039] Metal-organic framework material UiO-66-NH was prepared according to the method of Example 1 2

[0040] At room temperature, combining several different organic molecules with UiO-66-NH 2 Mix evenly at a mass ratio of 1:5, grind for 8 minutes, and small organic molecules include curcumin, p-toluic acid, 2-aminoterephthalic acid, benzoic acid, isophthalic acid, and dipicolinic acid. The obtained product is washed, centrifuged, and dried to obtain two-dimensional MOFs nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com