Production method of special titanium dioxide for decorative base paper

A technology of decorative base paper and production method, which is applied in the field of production of titanium dioxide for decorative base paper and special titanium dioxide for decorative base paper, can solve the problems of decorative base paper constraints, poor practicability, unstable quality, etc. Effects of morphology, resistance to aging and syneresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

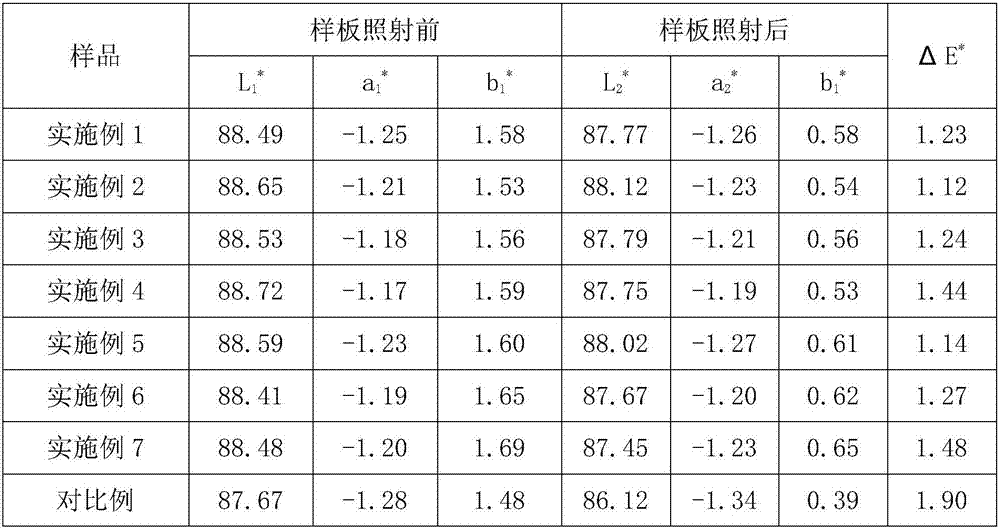

Examples

Embodiment 1

[0028] ⑴Weigh 2000gTiO 2 Add the first product to 3000g desalted water, stir to make a slurry of about 600g / L, then add 12g SiO 2 (0.2%) sodium silicate solution, adjust pH value 9.56 with 20% sulfuric acid, sand mill, make TiO 2 Dispersion reaches D99 2 The control of pH9.5-10 of silicate and slurry is to prevent silicon from agglomerating and strengthen silicon and TiO 2 combination.

[0029](2) Put the ground slurry into the coating tank, heat it in a water bath to raise the temperature to 51.2°C, and add desalted water to dilute to 300g / L.

[0030] (3) Quickly (5 minutes) add 160ml of 100g / L (0.8%) aluminum sulfate solution, and stir for 60 minutes, wherein the addition amount converted from 160ml of aluminum sulfate solution is calculated as Al 2 o 3 with TiO 2 The mass ratio is calculated as 0.8%, that is, after adding Al 2 o 3 The amount of TiO 2 0.8% of mass.

[0031] ⑷Add 400ml50g / L (1.0%) sodium phosphate solution, that is, after adding P 2 o 5 The amount ...

Embodiment 2

[0037] ⑴Weigh 2000gTiO 2 Add the first product to 3400g desalted water, stir to make a slurry of about 600g / L, then add 12g SiO 2 (0.2%) sodium silicate solution, adjust the pH value to 9.82 with 20% sulfuric acid, and sand mill to reach D99<1.0 μm.

[0038] (2) Put the ground slurry into the coating tank, heat it in a water bath to raise the temperature to 56.6°C, add desalted water to dilute to 310g / L.

[0039] (3) Quickly (5 minutes) add 200ml of 100g / L (1.0%) aluminum sulfate solution and stir for 60 minutes.

[0040] (4) Add 500ml of 50g / L (1.25%) sodium phosphate solution for 60 minutes. pH 5.02.

[0041] (5) Curing at 60°C for 60 minutes.

[0042] ⑹Under the condition of maintaining pH=5.0-5.5, add 500ml100g / L (2.5%) NaAlO 2 solution and sulfuric acid solution (20% H 2 SO 4 ), feed time 120 minutes.

[0043] (7) Adjust the pH value to 7.61 with sodium hydroxide solution, and ripen at 60°C for 120 minutes.

[0044] ⑻ Filtration, washing, drying, and airflow crus...

Embodiment 3

[0046] ⑴Weigh 2000gTiO 2 Add the first product to 3000g desalted water, stir to make a slurry of about 600g / L, then add 12g SiO 2 Sodium silicate solution, adjust the pH value to 9.95 with 20% sulfuric acid, and sand mill to reach D99<1.0μm.

[0047] (2) Put the ground slurry into the coating tank, heat it in a water bath to raise the temperature to 58.6°C, and add desalted water to dilute to 300g / L.

[0048] (3) Quickly (10 minutes) add 240ml of 100g / L (1.2%) aluminum sulfate solution, and stir for 60 minutes.

[0049] (4) Add 600ml of 50g / L (1.5%) sodium phosphate solution for 60 minutes. pH 5.03.

[0050] (5) Curing at 55°C for 60 minutes.

[0051] ⑹Under the condition of maintaining pH=5.0-5.5, add 500ml100g / L (2.5%) NaAlO 2 solution and sulfuric acid solution (20% H 2 SO 4 ), feed time 120 minutes.

[0052] (7) Adjust the pH value to 7.75 with sodium hydroxide solution, and ripen for 240 minutes at 55°C.

[0053] ⑻ Filtration, washing, drying, and airflow crushin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com