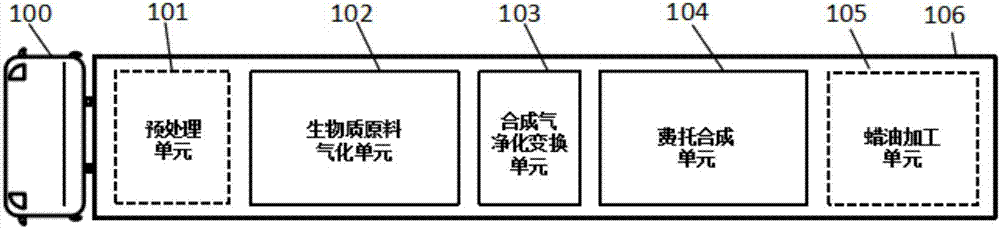

Method and system for preparing synthetic oil by using miniaturized biomass based on mobile platform

A mobile platform and biomass technology, applied in the preparation of liquid hydrocarbon mixture, gasification process, waste fuel, etc., can solve the problems of high transportation costs, ineffective use of biomass resources, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

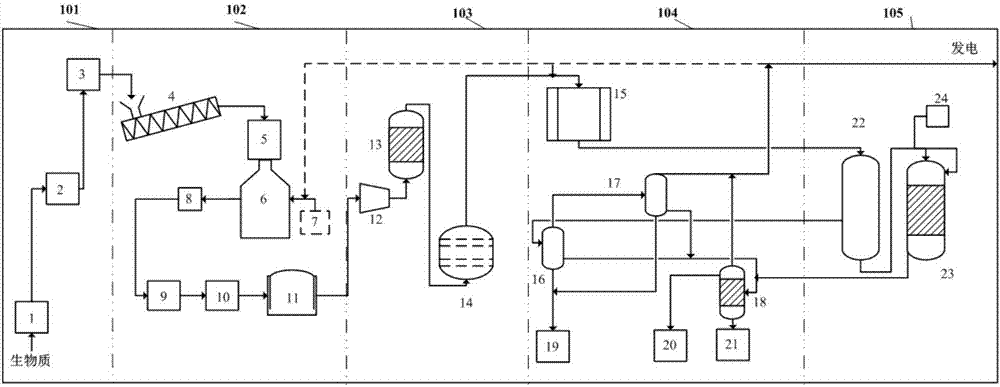

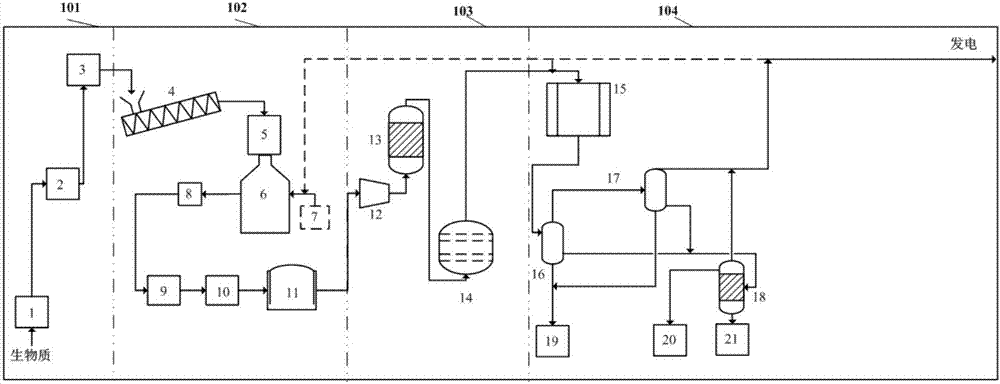

[0078] In this embodiment, straw is used as biomass raw material, the processing capacity is 12tpd, and the production capacity is 10bpd synthetic oil. All equipments are arranged and installed in one container, please refer to Figure 4 . The Fischer-Tropsch synthesis reactor 15 adopts a microchannel reactor, the Fischer-Tropsch synthesis catalyst adopts a bifunctional catalyst with cracking effect, and the Fischer-Tropsch synthesis oil product does not contain wax, so the wax oil processing unit 105 is not used. All light hydrocarbon tail gas is used for power generation to supply energy for the system. The specific process parameters are shown in Table 1.

Embodiment 2

[0080] In this embodiment, sapwood is used as biomass raw material, the processing capacity is 18tpd, and the production capacity is 30bpd synthetic oil. The Fischer-Tropsch synthesis reactor 15 adopts a microchannel reactor, the Fischer-Tropsch synthesis catalyst adopts a bifunctional catalyst with cracking effect, and the Fischer-Tropsch synthesis oil product does not contain wax, so the wax oil processing unit 105 is not used. All light hydrocarbon tail gas is used for power generation to supply energy for the system. The specific process parameters are shown in Table 1.

Embodiment 3

[0082] In this embodiment, straw briquette fuel is used as biomass raw material, the processing capacity is 45tpd, and the production capacity is 50bpd. The Fischer-Tropsch synthesis reactor 15 is a tubular fixed-bed reactor, and the catalyst is an iron-based catalyst. The oil produced by the Fischer-Tropsch synthesis contains wax oil, so a wax oil processing unit 105 is required. Half of the light hydrocarbon tail gas is recycled to the Fischer-Tropsch synthesis reactor, and the other half is used to generate electricity for the system. The specific process parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com