Method for preparing even and transparent conductive thin film by using electrostatic spinning

A transparent conductive film, electrospinning technology, applied in electrospinning, conductive/antistatic filament manufacturing, filament/thread forming, etc. Scalability, simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

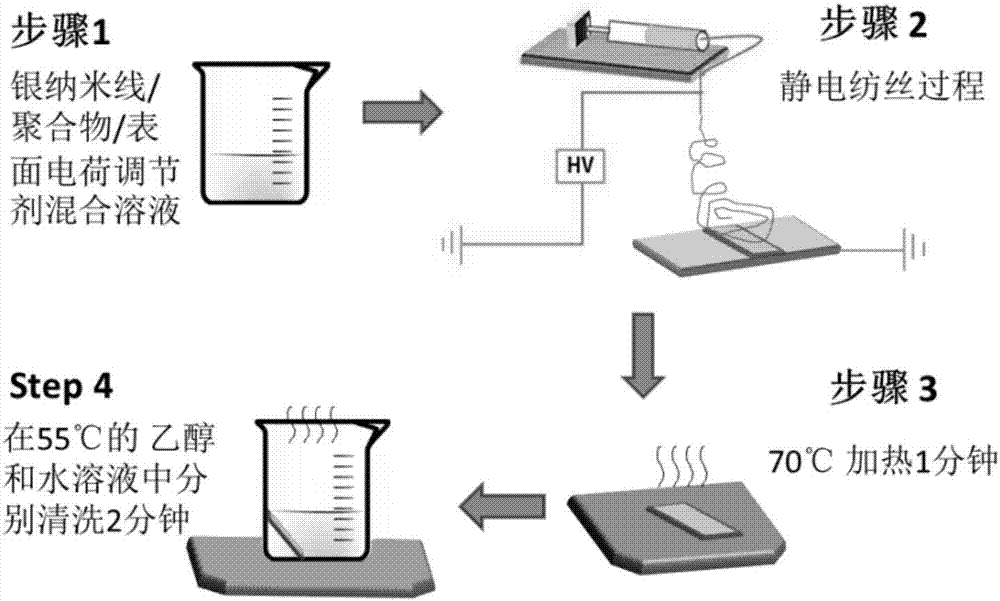

[0033] A method for preparing a uniform transparent conductive film by electrospinning, comprising the following production steps:

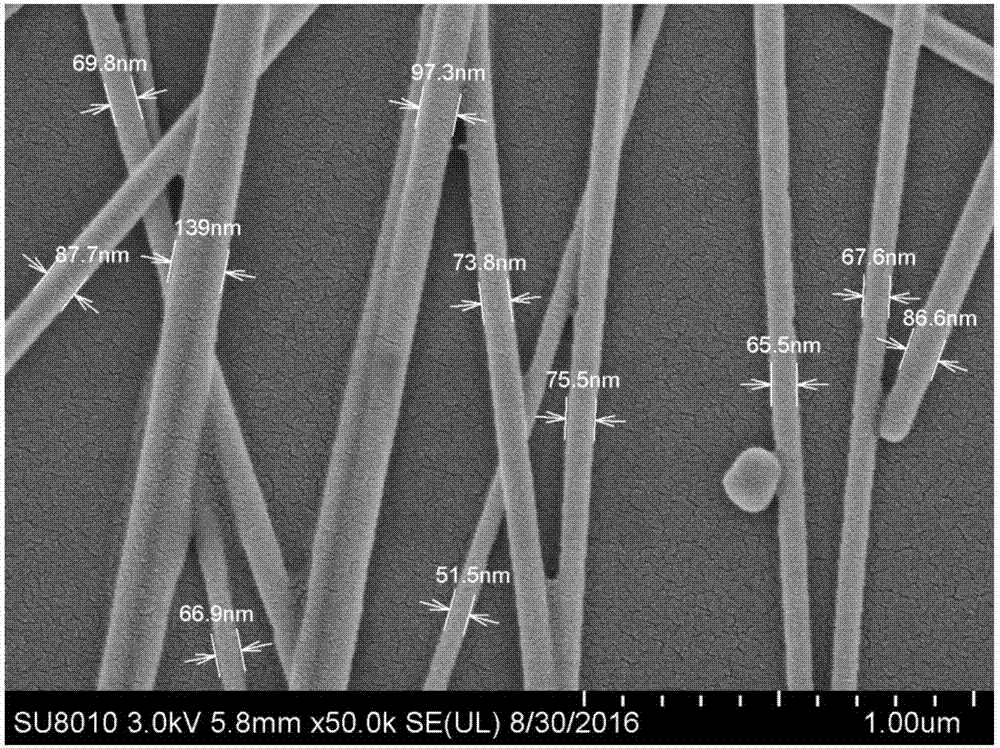

[0034] A, choosing diameter is 70nm, the silver nanowire 0.1g of length 20 μ m is conductive substance, chooses 2-amino-2-methyl-1-propanol 0.1g to be surface charge regulator, chooses polyethylene oxide (PEO) ( Molecular weight is 50000) 0.5g as macromolecular polymer, chooses water 9.3g as solvent preparation spinning solution;

[0035] Weigh the content of these components in the spinning solution, add all the weighed components into the glass bottle, stir for 5 minutes, and obtain a stable spinning solution;

[0036] B. Put the prepared spinning solution into the syringe of the electrospinning instrument, place the glass substrate directly under the needle of the electrospinning instrument, apply a high voltage of 30kv to the electrospinning instrument, and set the syringe of the electrospinning instrument The speed of liquid pushing is 0.5m...

Embodiment 2

[0041] A method for preparing a uniform transparent conductive film by electrospinning, comprising the following production steps:

[0042] A, choosing diameter is 70nm, the silver nanowire 0.1g of length 20 μ m is conductive substance, chooses 2-amino-2-methyl-1-propanol 0.1g to be surface charge regulator, chooses polyethylene oxide (PEO) ( Molecular weight is 50000) 0.5g as macromolecular polymer, chooses water 9.3g as solvent preparation spinning solution;

[0043] Weigh the content of these components in the spinning solution, add all the weighed components into the glass bottle, stir for 5 minutes, and obtain a stable spinning solution;

[0044] B. Put the prepared spinning solution into the syringe of the electrospinning apparatus, place the polyethylene terephthalate (PET) substrate directly under the needle of the electrospinning apparatus, and apply 30kv to the electrospinning apparatus The high pressure, and set the speed of the electrospinning instrument cylinder ...

Embodiment 3

[0049] A method for preparing a uniform transparent conductive film by electrospinning, comprising the following production steps:

[0050] A, choosing diameter is 35nm, the silver nanowire 0.1g of length 15 μ m is conductive material, chooses 2-amino-2-methyl-1-propanol 0.1g to be surface charge regulator, chooses polyethylene oxide (PEO) ( Molecular weight is 50000) 0.5g as macromolecular polymer, chooses water 9.3g as solvent preparation spinning solution;

[0051] Weigh the content of these components in the spinning solution, add all the weighed components into the glass bottle, stir for 5 minutes, and obtain a stable spinning solution;

[0052] B. Put the prepared spinning solution into the syringe of the electrospinning apparatus, place the polyimide (PI) substrate directly under the needle of the electrospinning apparatus, apply a high voltage of 30kv to the electrospinning apparatus, and set The speed of the syringe of the electrospinning instrument is 0.5mm / min, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com