Method for improving biological coal bed gas yield through coal bed origin fungi

A bio-coalbed methane and coalbed methane technology, applied in the field of production increase and coalbed methane mining, can solve the problems of low methane production and rate of biodegradation coal, unsatisfactory field application conditions, etc., to solve the problem of methane production rate, output and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

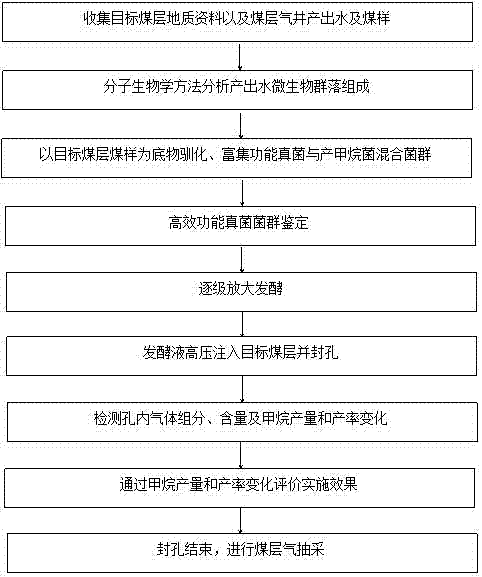

[0032] Embodiment 1: the method for improving biological coalbed methane output

[0033] The specific steps of the method are as follows:

[0034] In the first step, the target CBM field is an area in the south of the CBM field in the Qinshui Basin9 # For coal seams, collect relevant geological data, collect coal samples from coalbed methane reservoirs, produce water samples at the wellhead of coalbed methane, and use Miseq high-throughput sequencing technology to analyze the microbial community structure of the collected water samples;

[0035] The results show that the reservoir pressure is 4.3Mpa and the reservoir temperature is 35°C. The archaeal groups of methanogens are mainly methanogens, the bacteria are mainly Proteobacteria and Firmicutes, and the fungi are mainly Ascomycota and Basidiomycota.

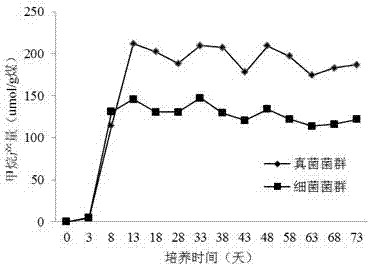

[0036] In the second step, using coal as the only carbon source, the microbial flora that degrades coal and produces methane is enriched from the produced water samples. T...

Embodiment 2

[0043] Embodiment 2: the method for improving bituminous coal bio-coal-bed methane output

[0044] The specific steps of the method are as follows:

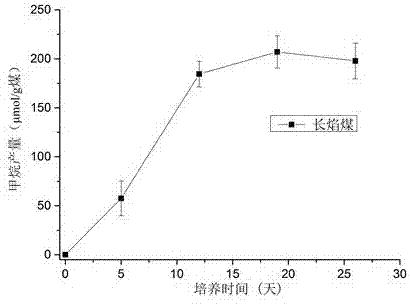

[0045] In the first step, the target coal sample is a long-flame coal sample obtained from the northern area of Qinshui Basin, and the source of the bacteria is the mixed bacteria group of fungi and methanogens enriched in Example 1.

[0046] In the second step, the target long-flame coal sample was used as the only carbon source to carry out the coalbed methane experiment of microbial degradation of coal products. The pH of the culture environment was 7.0, and the culture temperature was 35°C. The antibiotics added were ampicillin at a final concentration of 0.1 mM and streptomycin at a final concentration of 0.2 mM.

[0047] The third step is to cultivate under laboratory conditions for 30 days, and evaluate the gas production effect. The gas production of long-flame coal reaches 200 μmol / g coal, and the bacterial group sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com