Preparation method and application of banana cellulose film

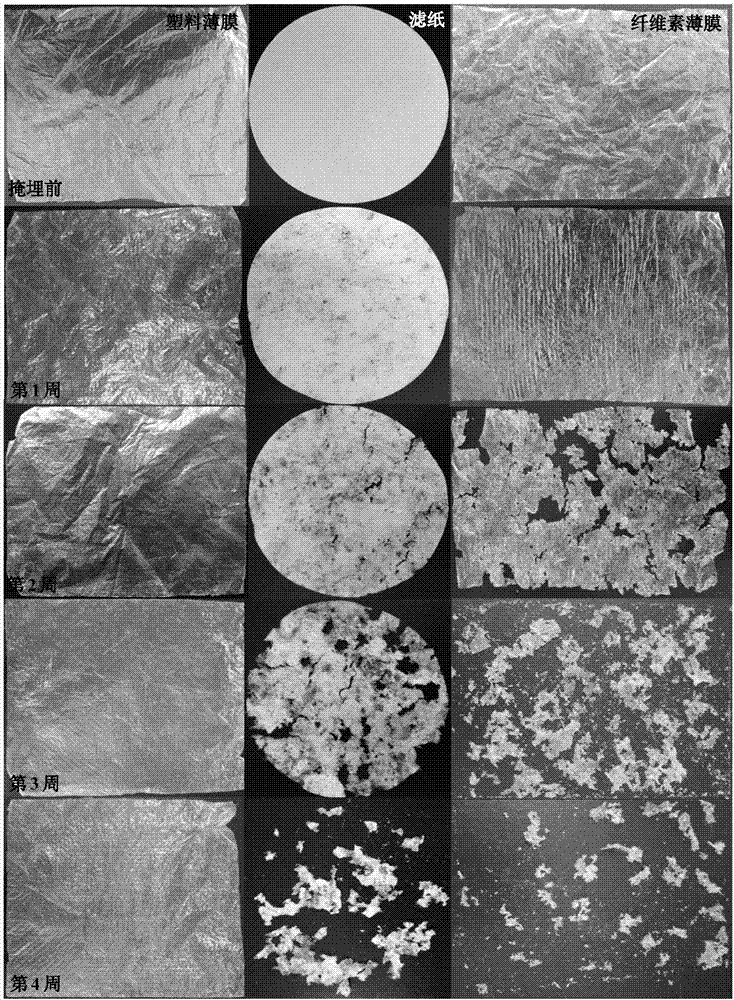

A cellulose film and banana technology, applied in the field of fresh-keeping packaging, can solve the problems of decreased mechanical strength, poor film-forming properties, and damage to the natural characteristics of cellulose, and achieve the effect of good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

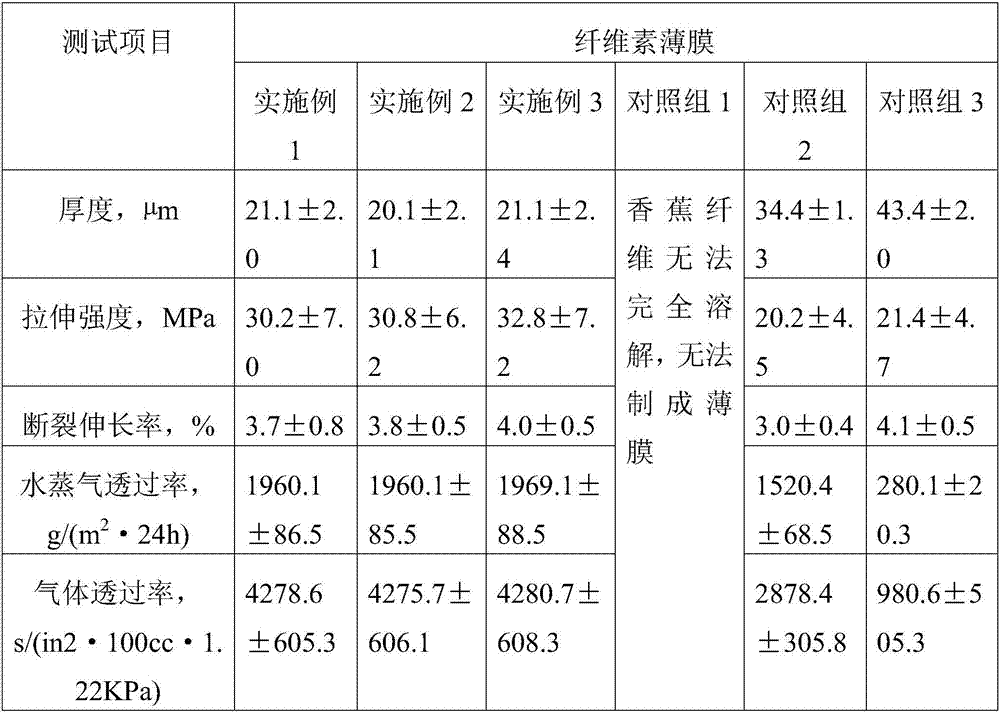

Examples

Embodiment 1

[0025] A preparation method for banana cellulose film, comprising the following steps:

[0026] (1) Banana stalks are scraped to obtain banana stalk fibers, cut, add 1.2g / L H 2 SO 4 After the solution is heated in a water bath, the solid-to-liquid weight ratio of the banana stalk fiber to sulfuric acid is 1:16, the water bath heating temperature is 47°C, the water bath heating time is 1.8h, and the banana stalk fiber is washed with water until the pH is neutral;

[0027] (2) Place the banana stalk fiber treated in step (1) in a 156g / L NaOH solution and then heat it in a water bath. The temperature of the water bath heating is 27° C., and the water bath heating time is 1 h. Wash it with water until the pH is neutral. Obtain alkalized fiber and dry it for later use;

[0028] (3) Add the dried alkalized fiber into the ionic liquid of 1-allyl-3-methylimidazolium chloride salt, stir and heat to dissolve, the stirring speed is 180r / min, the dissolution temperature is 86°C, and the...

Embodiment 2

[0032] A preparation method for banana cellulose film, comprising the following steps:

[0033] (1) Banana stalks are scraped to obtain banana stalk fibers, cut, add 2.8g / L H 2 SO 4 After the solution is heated in a water bath, the solid-to-liquid weight ratio of the banana stem fibers and sulfuric acid is 1:23, the water bath heating temperature is 52°C, the water bath heating time is 2.2h, and the banana stem fibers are washed with water until the pH is neutral;

[0034] (2) Put the banana stalk fiber treated in step (1) in 246g / L NaOH solution and then heat it in a water bath. , to obtain alkalized fibers, and dry them for later use;

[0035] (3) Add the dried alkalized fiber into the ionic liquid of 1-allyl-3-methylimidazolium chloride salt, stir and heat to dissolve, the stirring speed is 220r / min, the dissolution temperature is 100°C, and the dissolution time is 3.5h , the solution was poured evenly on a glass plate, and quickly scraped with a film applicator to form ...

Embodiment 3

[0039] A preparation method for banana cellulose film, comprising the following steps:

[0040] (1) Banana stalks are scraped to obtain banana stalk fibers, cut, add 2.4g / L H 2 SO 4 After the solution is heated in a water bath, the solid-to-liquid weight ratio of the banana stem fiber and sulfuric acid is 1:22, the water bath heating temperature is 52°C, the water bath heating time is 2.0h, and the banana stem fiber is washed with water until the pH is neutral;

[0041] (2) Put the banana stalk fiber treated in step (1) in 210g / L NaOH solution and then heat it in a water bath. , to obtain alkalized fibers, and dry them for later use;

[0042] (3) Add the dried alkalized fiber into the ionic liquid of 1-allyl-3-methylimidazolium chloride salt, stir and heat to dissolve, the stirring speed is 200r / min, the dissolution temperature is 93°C, and the dissolution time is 3.2h , the solution was poured evenly on a glass plate, and quickly scraped with a film applicator to form a un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com