Silazane hybrid cyanate ester adhesive

A cyanate ester and silazane technology, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor high temperature oxidation resistance and insufficient temperature resistance, and achieve improved high temperature performance and improved Temperature resistance and oxidation resistance, the effect of improving high temperature resistance and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The preparation method of high temperature resistant structural adhesive of the present invention is:

[0065] Add a certain amount of auxiliary filler to 100 parts of cyanate ester or its modified difunctional, oligomer or multifunctional cyanate ester or its prepolymer and mix evenly, then add the corresponding curing agent, mix thoroughly and then degas After 5-10 minutes, it can be used as a high temperature resistant structural adhesive.

[0066] The curing method of the high temperature resistant structural adhesive of the present invention is:

[0067] The adhesive is pre-cured at 30-70°C, preferably 45-60°C, for 1-5 hours, and then heated to 130-240°C, preferably 150-200°C, and the curing time is 1-4 hours.

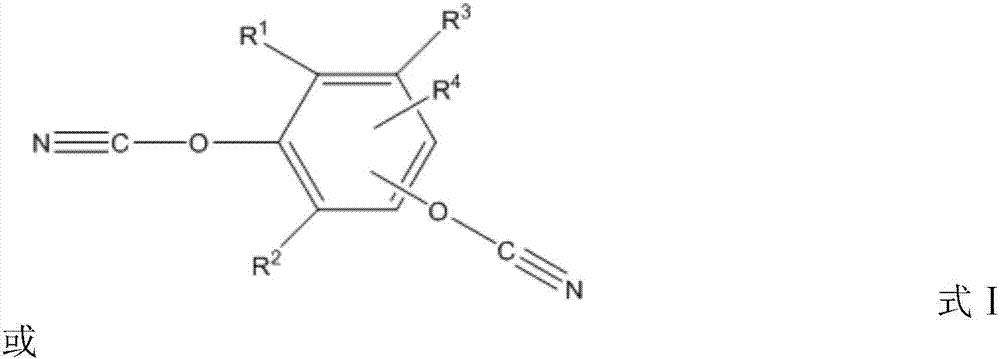

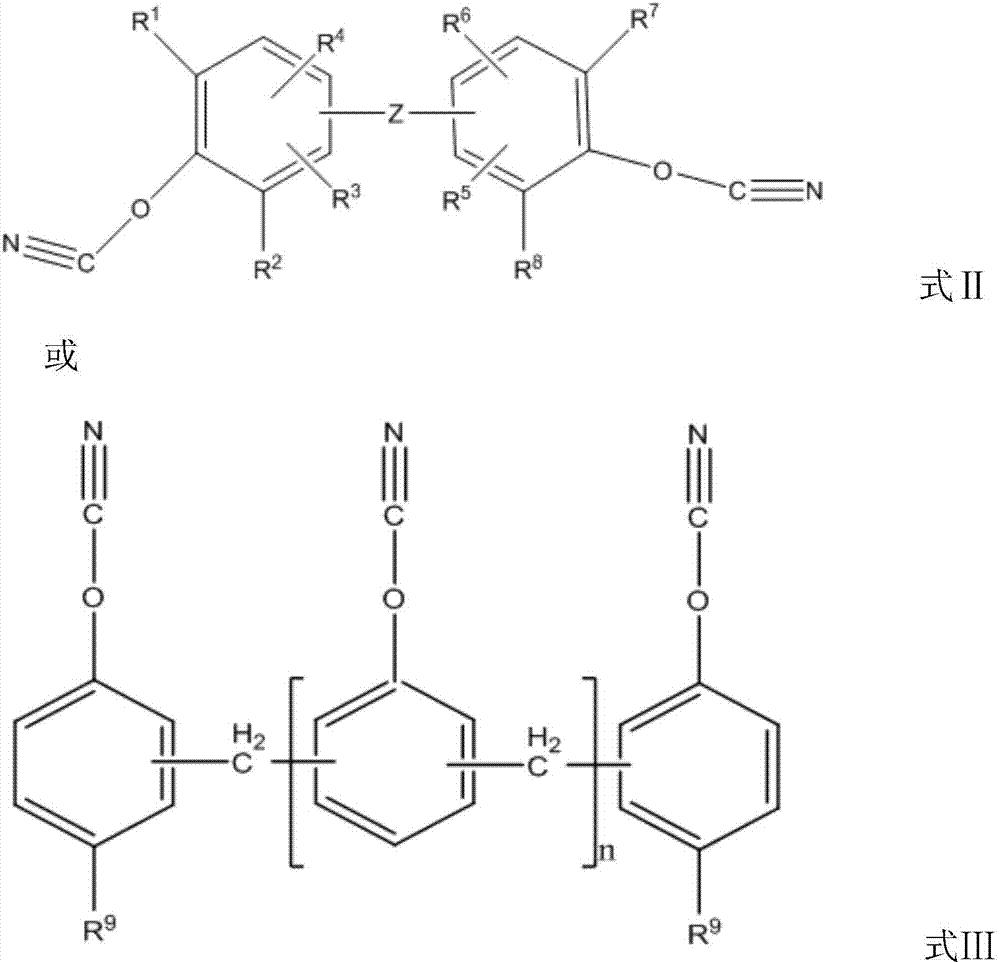

[0068] Among them, the cyanate is a mixture of one or more of difunctional or multifunctional cyanate, cyanate oligomers, and cyanate prepolymers; the cyanate can be liquid cyanate or cyanate The organic solvent solution of acid ester, the concentration o...

Embodiment 1

[0110] In this embodiment, 80 parts of SiO are added to 100 parts of 4,4'-bis(phenylcyanate)ethane (L10). 2 , 40 parts of ZrB 2 , 10 parts of SiC, 10 parts of TiC as solid filler, 3 parts of SiO 2 As chopped fiber, 3 parts Fe 2 o 3 As a solid pigment, mix thoroughly, then add 20 parts of silazane, and vacuum degass for 5 minutes to obtain a high temperature resistant silazane hybrid cyanate adhesive. The adhesive of the present invention is used in plastics, metals, graphite, ceramics and For the bonding of composite materials, the structural formula of 4,4'-bis(phenylcyanate)ethane (L10) is shown in Formula 1, and the structural formula of silazane is shown in Formula 2.

[0111] The curing process of the high temperature resistant silazane hybrid cyanate adhesive in this example is as follows: pre-cure at 45°C for 2 hours, then raise the temperature to 150°C for 2 hours, cool to room temperature, and test the cured adhesive. Room temperature bond strength of high tempera...

Embodiment 2

[0120]In this embodiment, 80 parts of SiO are added to 100 parts of 4,4'-bis(phenylcyanate)ethane (L10). 2 , 40 parts of ZrB 2 , 10 parts of SiC, 10 parts of TiC as solid filler, 3 parts of SiO 2 As chopped fiber, 3 parts Fe 2 o 3 As a solid pigment, mix well, then add silazane, the mass parts of silazane are (a) 5 parts, (b) 10 parts, (c) 15 parts, (d) 20 parts, (e) 25 parts, (f) 30 parts, after vacuum degassing for 5 minutes, obtain high temperature resistant silazane hybrid cyanate adhesive;

[0121] The present invention selects steel as the bonding substrate, wherein, the structural formula of 4,4'-bis(phenylcyanate)ethane (L10) is shown in Formula 1, and the structural formula of silazane is shown in Formula 2.

[0122] The curing process of the high temperature resistant silazane hybrid cyanate adhesive in this example is as follows: pre-cure at 45°C for 2 hours, then raise the temperature to 150°C for 2 hours, cool to room temperature, and test its room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com