Bacteria nutrient culture medium and preparation method thereof

A technology of culture medium preparation and bacterial nutrition, applied in biochemical equipment and methods, measuring devices, microbe determination/inspection, etc., to achieve efficient and rapid treatment, growth promotion, and low fat content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The method for preparing bacterial nutrient medium of the present invention, bacterium is the pathogenic bacterium that causes rabbit to fall ill, and preparation method comprises the following steps:

[0060] Step 1, preparing rabbit meat powder;

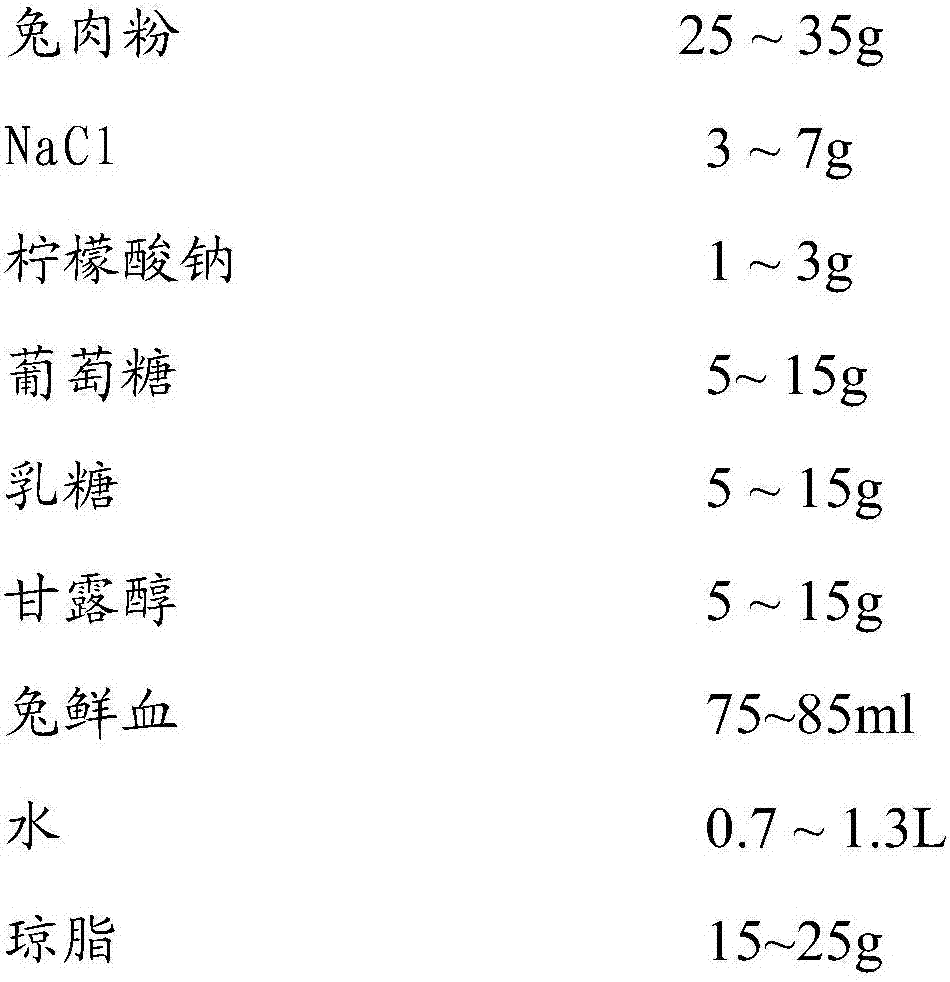

[0061] Step 2: Take 0.6-1.0L of water and put it into a beaker, measure 25-35g of rabbit meat powder, 3-7g of NaCl, 1-3g of sodium citrate, 5-15g of glucose, 5-15g of lactose, and 5-15g of mannitol to dissolve Put in water and stir evenly to get a uniform mixed solution, then measure 15-25g of agar and add it to the mixed solution, heat the mixed solution at 90°C-98°C until the agar is completely melted, and keep stirring and mixing during this heating process liquid;

[0062] Step 3, adding 0.1-0.3 L of water to the mixed solution obtained in step 2 and adding agar, and then adding a pH regulator to adjust the pH value of the mixed solution to 6.8-7.5;

[0063] Step 4, sterilizing the mixed solution obtained in step 3 aft...

Embodiment 1

[0071] Step 101, preparing rabbit meat powder;

[0072] Step 1011, take 150g of raw rabbit meat, add 170ml of water and boil for 10 minutes, remove the water and grind into meat paste;

[0073] Step 1012, add protease to the meat paste obtained in step 1011 at an amount of 30,000 U / g and stir evenly, and place the uniformly stirred meat paste at 60° C. for 12 hours to obtain the heat-preserved meat paste. Add 400ml of water to the meat paste and boil for 15 minutes to inactivate the protease in the meat paste after heat preservation, and form rabbit meat slurry;

[0074] Step 1013, centrifuge the rabbit meat slurry obtained in step 1012 at a speed of 3000 rpm for 5 minutes in a centrifuge, filter out the residue and oil, obtain the filtered rabbit meat slurry, and process the filtered rabbit meat The slurry is dried to form rabbit meat powder.

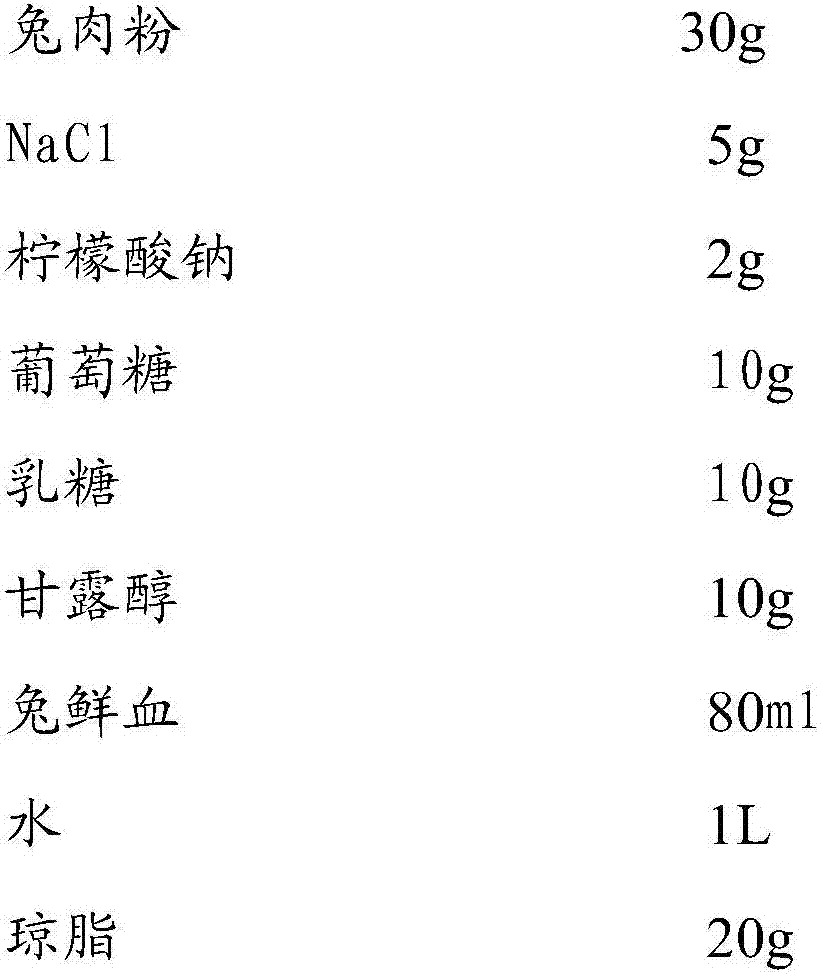

[0075] Step 102, take 0.8L of water and put it into a beaker, take 30g of rabbit meat powder, 5g of NaCl, 2g of sodium citrate, 10g...

Embodiment 2

[0080] Step 101, preparing rabbit meat powder;

[0081] Step 1011, take 140g of raw rabbit meat, add 150ml of water and cook for 8 minutes, remove the water and grind into meat paste;

[0082]Step 1012, add protease to the meat paste obtained in step 1011 at an amount of 0.29 million U / g and stir evenly, and place the uniformly stirred meat paste at 65° C. for 11 hours to obtain the meat paste after heat preservation. Boil 300ml of meat paste in water for 12 minutes to inactivate the protease in the meat paste after heat preservation, and form rabbit meat slurry;

[0083] Step 1013, centrifuge the rabbit meat slurry obtained in step 1012 at a speed of 3200 rpm for 4 minutes in a centrifuge, filter out the residue and oil, obtain the filtered rabbit meat slurry, and process the filtered rabbit meat The slurry is dried to form rabbit meat powder.

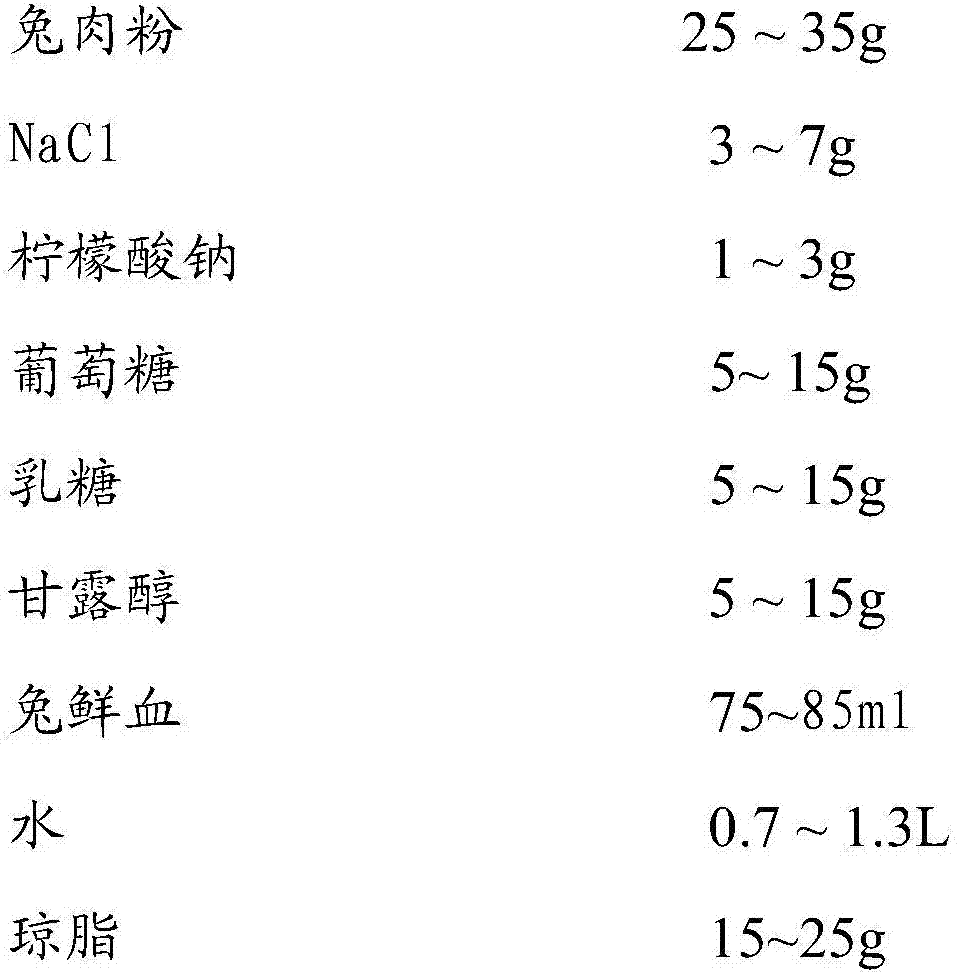

[0084] Step 102, take 1.0L of water and put it into a beaker, take 35g of rabbit meat powder, 3g of NaCl, 3g of sodium citrate, 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com