Preparation method for azithromycin micro-emulsion eye drops

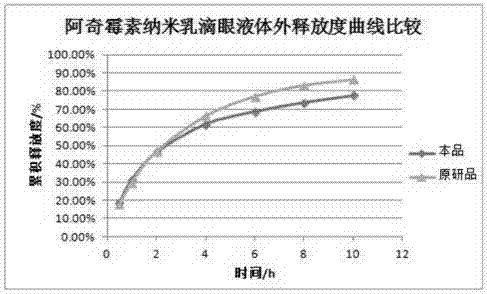

A technology for azithromycin and eye drops, which is applied in the fields of emulsion delivery, medical preparations containing active ingredients, and pharmaceutical formulas, and can solve problems such as inaccurate dosage, inaccurate dosage, and poor reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] A kind of azithromycin microemulsion eye drop, it comprises the following components according to the total mass percentage of raw materials:

[0108]

[0109] Preparation:

[0110] 1) After mixing and dissolving Miglyol 812, Tween 80, and polyoxyethylene castor oil, stir continuously at 40-50°C to form solution Ⅰ;

[0111] 2) Dissolve citric acid and sodium citrate with water for injection, the amount of water for injection is 50% of the total amount, then add the prescribed amount of azithromycin, L-cysteine, mannitol and benzalkonium chloride, at 40-50°C Stir continuously, and adjust the pH to 6.5 with a pH regulator to form solution II;

[0112] 3) Slowly inject and drop solution I into solution II, while stirring continuously at 40-50°C, stirring evenly to form solution III;

[0113] 4) Weigh the carboxylated chitosan, place it in water for injection (the amount is 20% of the total amount), and after the carboxylated chitosan is dissolved, add solution III, an...

Embodiment 2

[0116] A kind of azithromycin microemulsion eye drop, it comprises the following components according to the total mass percentage of raw materials:

[0117]

[0118] The preparation method is the same as that of Example 1 to obtain the finished product of Example 2 microemulsion eye drops.

Embodiment 3

[0120] A kind of azithromycin microemulsion eye drop, it comprises the following components according to the total mass percentage of raw materials:

[0121]

[0122] The preparation method is the same as that of Example 1 to obtain the finished product of Example 3 microemulsion eye drops.

PUM

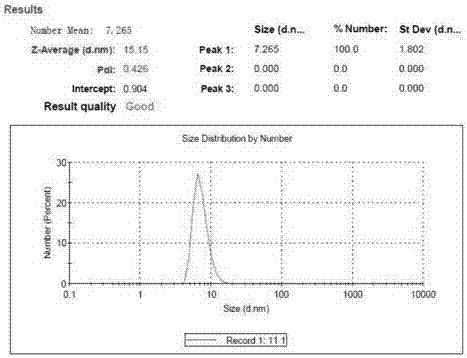

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Zeta potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com