Method for recycling carbon-based microporous materials to treat nitrogen oxide waste gas

A technology of microporous materials and nitrogen oxides, applied in chemical instruments and methods, separation methods, gas treatment, etc. Poor reusability, poor adsorption performance, etc., to achieve high-performance recycling, rapid and thorough reduction reaction, and improved adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

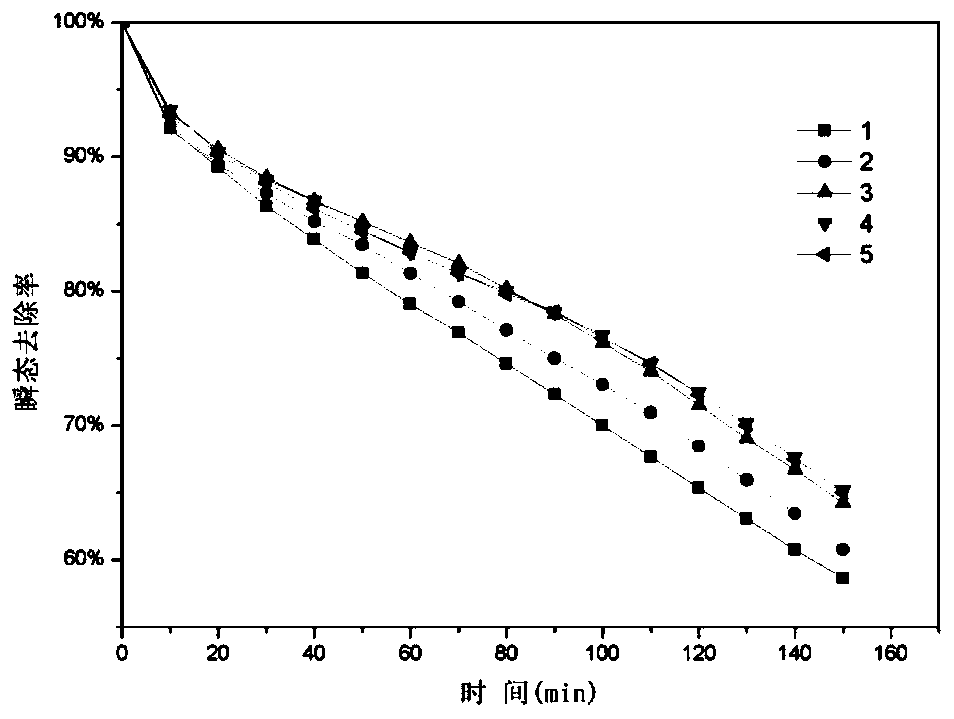

[0047] Embodiment 1: by above-mentioned (one) method preparation simulation gas, record relative humidity is 40%, oxygen volume fraction is 10.3%, nitric oxide volume fraction is 520ppm, makes gas pass through the adsorption column in above-mentioned (two), simultaneously Start timing, record the concentration of nitric oxide every 10 minutes, absorb for a total of 150 minutes, and make a curve of the transient removal rate of nitric oxide with time (see figure 1 ).

[0048] Take out the above-mentioned activated carbon after 150 minutes of adsorption, put it in the reaction kettle, add 1.25ml of ammonia solution with a mass concentration of 7%, mix it, place the closed reaction kettle in an oven at 180°C, stop heating after 30 minutes, and open the reaction kettle after cooling down , then heated and dried at 180°C for 90 minutes, took out the dried activated carbon, cooled to room temperature, repeated the above steps and used the regenerated activated carbon to carry out th...

Embodiment 2

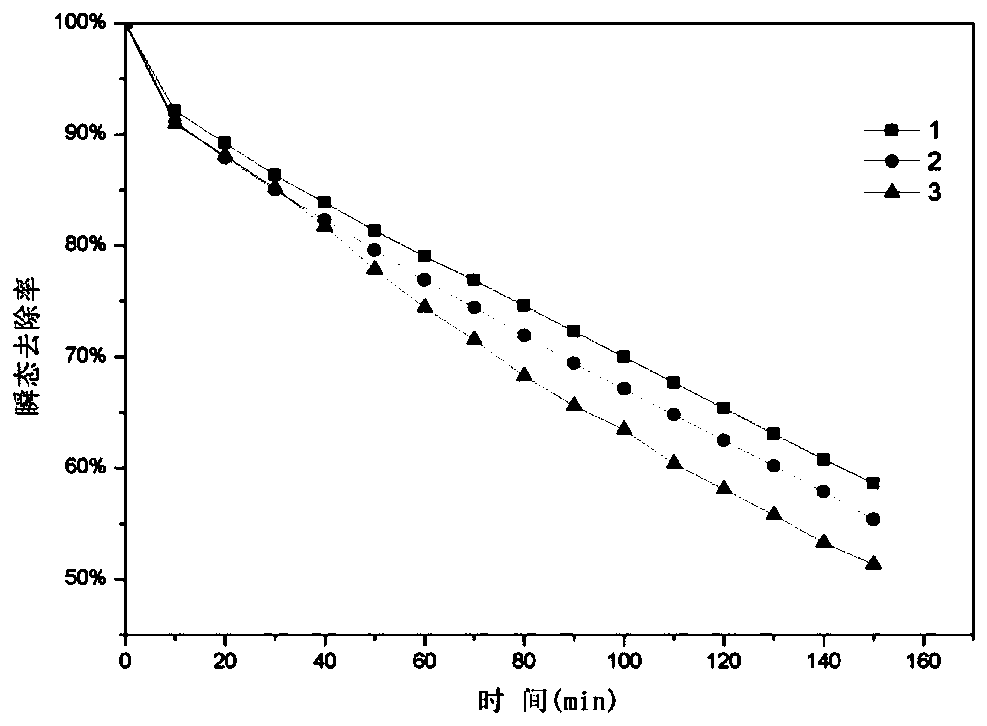

[0049] Embodiment 2: according to above-mentioned (1) method preparation simulated gas, record relative humidity is 40%, oxygen volume fraction is 10.3%, nitric oxide volume fraction is 520ppm, makes gas pass through the adsorption column in above-mentioned (two).

[0050] Take out the above-mentioned activated carbon after 150min of adsorption, put it in the reaction kettle, add 2.5ml of ammonia solution with a mass concentration of 7%, mix, put the closed reaction kettle in an oven at 200°C, stop heating after 30min, and open the reaction kettle after cooling down , and then heated and dried at 180°C for 90 minutes, took out the dried activated carbon, cooled to room temperature, and repeated the above steps to use the regenerated activated carbon for adsorption.

Embodiment 3

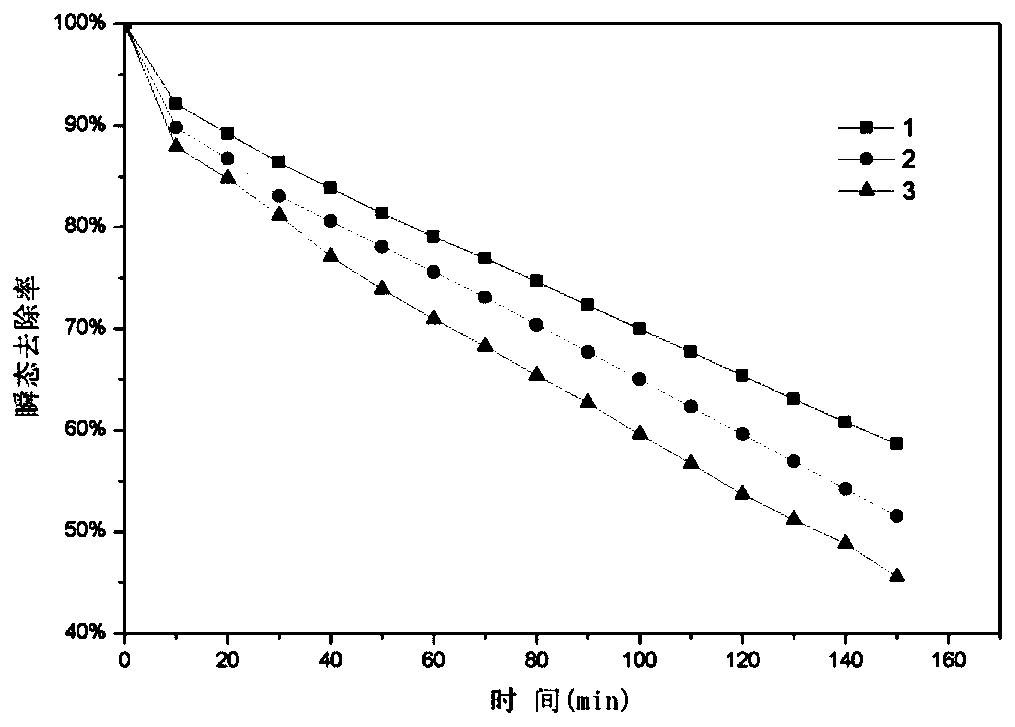

[0051] Embodiment 3: prepare simulated gas by above-mentioned (1) method, record relative humidity is 40%, oxygen volume fraction is 10.3%, nitric oxide volume fraction is 520ppm, makes gas pass through the adsorption column in above-mentioned (two).

[0052] The activated carbon after the above-mentioned adsorption for 150min was taken out, placed in a reaction kettle, added with 5ml of ammonia solution with a mass concentration of 7%, mixed, the closed reaction kettle was placed in an oven at 190°C, and the heating was stopped after 30min, and the reaction kettle was opened after cooling down. Reheat and dry at 180°C for 90 minutes, take out the dried activated carbon, cool to room temperature, repeat the above steps and use the regenerated activated carbon for adsorption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com