An organic waste gas recovery and treatment process and complete set of equipment

A technology for recovery and treatment of organic waste gas, applied in gas treatment, steam condensation, separation methods, etc., can solve problems such as gas cannot be compressed and condensed, difficult to condense, system collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

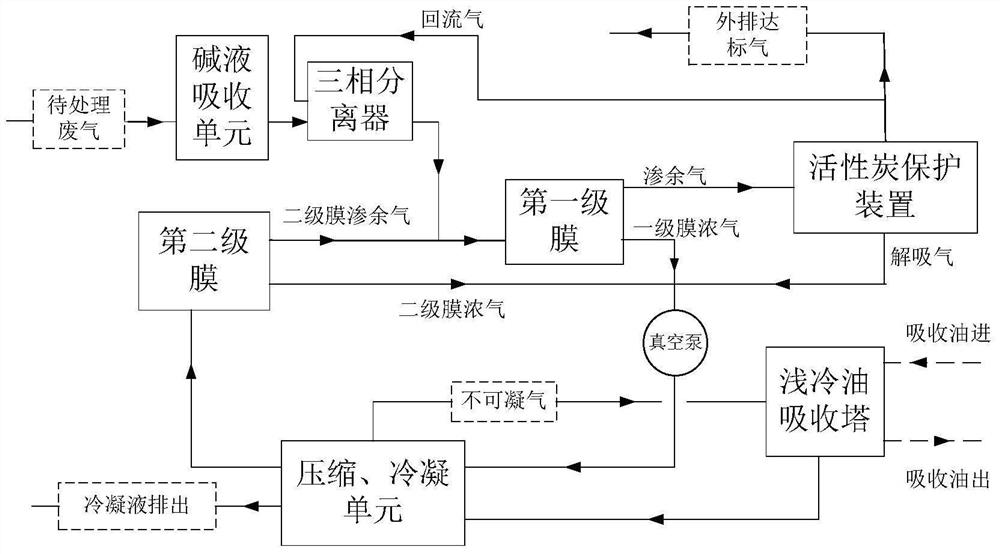

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

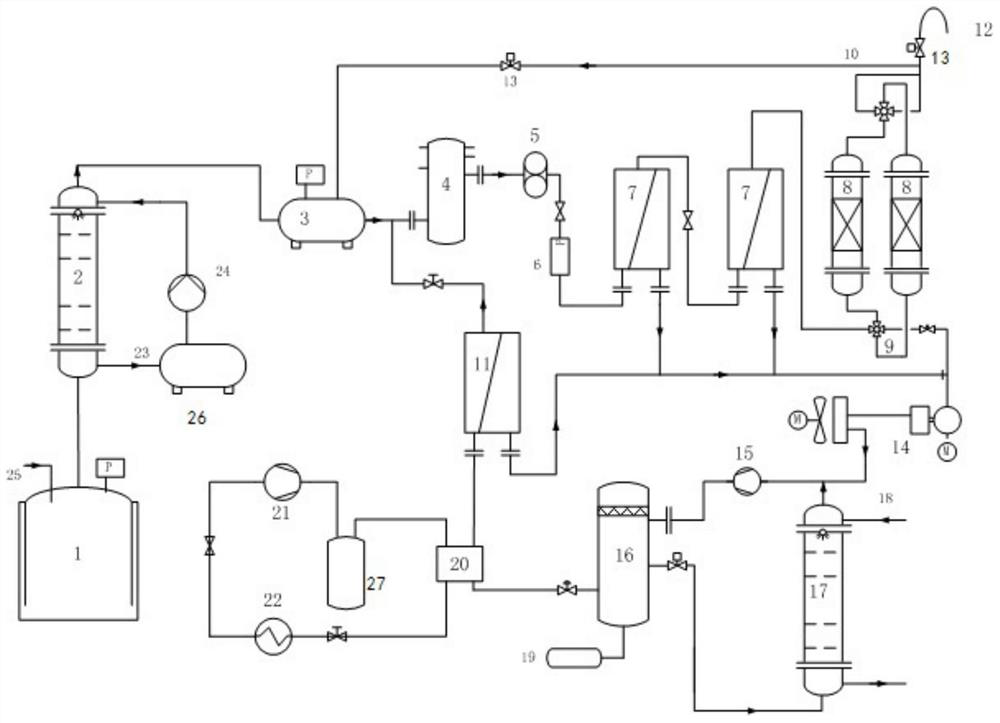

Embodiment 1

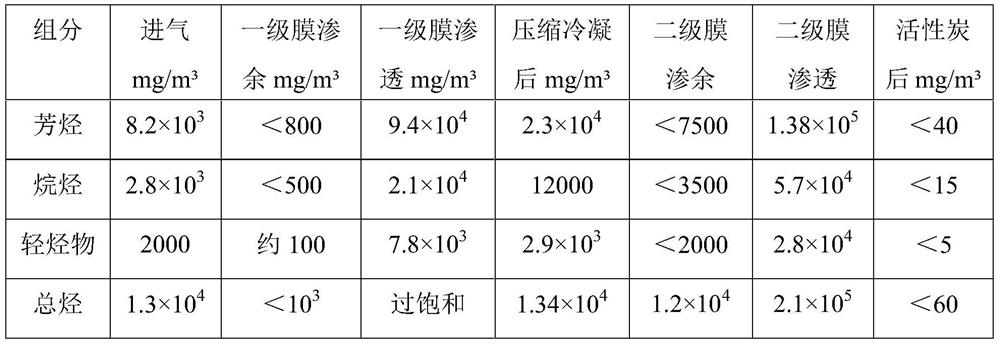

[0103] Vaulted tanks in the heavy oil tank farm emit organic waste gas from time to time. The source of exhaust gas is the oil gas produced by the volatilization of oil in the heavy oil vault tank. The main pollutant composition (in terms of concentration) in the exhaust gas is the volatilized gas of alkane components, and the concentration of non-methane total hydrocarbons reaches 1.3×104mg / m 3 , of which alkanes account for 86%, most of which are condensable alkanes (carbon number about 5), with a concentration of 9600mg / m 3 , Aromatic compound 8200mg / m 3 , in which the non-condensable gas is mainly the pyrolysis product of the reaction process, about 3400mg / m 3 , average gas flow rate 10Nm 3 / h. The process equipment adopts figure 2 The process flow shown, where the membrane area is 35m 2 , the primary membrane is in the form of a roll-type membrane module, with an area of 30m 2 , secondary membrane 5m 2 Disc components are used. Activated carbon adsorption tank ...

Embodiment 2

[0109] Treat the exhaust gas from the catalytic cracking unit of the refinery and the breathing valve of the waste oil storage tank. The waste gas consists of 93% nitrogen and 7% hydrocarbons. Hydrocarbons mainly include alkanes, olefins, aromatics, ethers, and halogenated hydrocarbons, as well as sulfur-containing components such as hydrogen sulfide and mercaptans. The average gas flow rate is 100Nm 3 / h, device membrane area 130m 2 , primary membrane 100m 2 , which are five roll-type membrane modules connected in parallel, and the secondary membrane is a disc-type membrane module with a filling area of 30m 2 . The volume of each activated carbon adsorption tank is 4.5m 3 , using coconut shell activated carbon loaded with basic functional groups, the particle size is 2mm. Process device parameters such as temperature, pressure, flow rate, etc. are shown in Table 3. The total gas composition, total non-methane hydrocarbons and the concentration of representative compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com