Method for producing artificial wollastonite powder by utilizing Bayer red mud

A Bayer red mud and wollastonite technology, applied in the direction of non-metallic elements, can solve environmental pollution and other problems, achieve stable physical and chemical properties, good effect, and increase the effect of heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

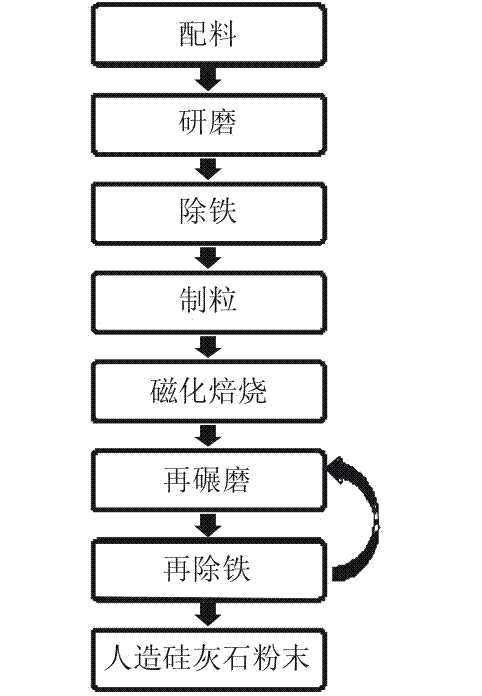

Image

Examples

Embodiment 1

[0039] The Bayer red mud used in this embodiment contains 1% by weight of sodium hydroxide and 26% by weight of iron;

[0040] 1. Ingredients, take Bayer red mud, add stearic acid of 0.1% by weight of Bayer red mud, and the ingredients are completed;

[0041] 2. Grinding, grinding the ingredients into a 120-200 mesh slurry with a wet ball mill;

[0042] 3. For iron removal, use a wet magnetic separator with a magnetic strength of 6500 Gaust to perform three times of strong magnetic re-selection to remove iron from the red mud slurry; the iron content in the slurry after iron removal is: 8.97%;

[0043] 4. Granulating, add the slurry after iron removal to Bayer red mud with 1% wood sawdust and 10% carbon powder, stir evenly, and then send it to the granulator to make granules to be fired with a particle size of 2~5cm;

[0044] 5. Magnetization roasting. The pellets to be fired that are naturally dried are put into a rotary kiln and magnetized and roasted for 3 hours at a temp...

Embodiment 2

[0052] The Bayer red mud used in this embodiment contains 2.8% by weight of sodium hydroxide and 32% by weight of iron;

[0053] 1. Ingredients, add dilute hydrochloric acid with an acid-base molar equivalent concentration of 10% to the Bayer red mud to neutralize the sodium hydroxide in the Bayer red mud, and then add 0.3% benzenesulfonic acid by weight of the Bayer red mud. Finish;

[0054] 2. Grinding, grinding the ingredients into a 120-200 mesh slurry with a wet ball mill;

[0055] 3. For iron removal, use a wet magnetic separator with a magnetic strength of 8000 Gaust to perform three times of strong magnetic re-selection to remove iron from the red mud slurry; the iron content in the slurry after iron removal is: 11.2%;

[0056] 4. Granulating, add the slurry after iron removal to 3% of the weight of Bayer red mud plant fiber and 10% of carbon powder, stir evenly, and then send it to the granulator to make granules to be fired with a particle size of 2~5cm;

[0057]5....

Embodiment 3

[0065] The Bayer red mud used in this embodiment contains 4.7% by weight of sodium hydroxide and 29% by weight of iron;

[0066] 1. Ingredients, add dilute hydrochloric acid with an acid-base molar equivalent concentration of 10% to the Bayer red mud to neutralize the sodium hydroxide in the Bayer red mud, and then add stearic acid with a weight of 0.3% of the Bayer red mud. Finish;

[0067] 2. Grinding, grinding the ingredients into a 120-200 mesh slurry with a wet ball mill;

[0068] 3. For iron removal, use a wet magnetic separator with a magnetic strength of 7000 Gaust to perform three times of strong magnetic re-selection to remove iron from the red mud slurry; the iron content in the slurry after iron removal is: 8.7%;

[0069] 4. Pelletizing, adding 3% wood sawdust and 10% carbon powder to the Bayer red mud slurry after iron removal, stirring evenly, and then sending it to the granulator to make pellets to be fired with a particle size of 2-5cm;

[0070] 5. Magnetizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hygroscopicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com