Titanium dioxide hollow micro-nano spheres as well as preparation method and application thereof

A technology of titanium dioxide and micro-nanospheres, which is applied in the field of photocatalysis, can solve the problems that the properties of titanium dioxide hollow nanospheres cannot be precisely controlled, and the process of titanium dioxide hollow nanospheres is difficult to predict, so as to protect agglomeration and excessive growth, improve catalytic performance, and avoid burning The effect of the erosion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

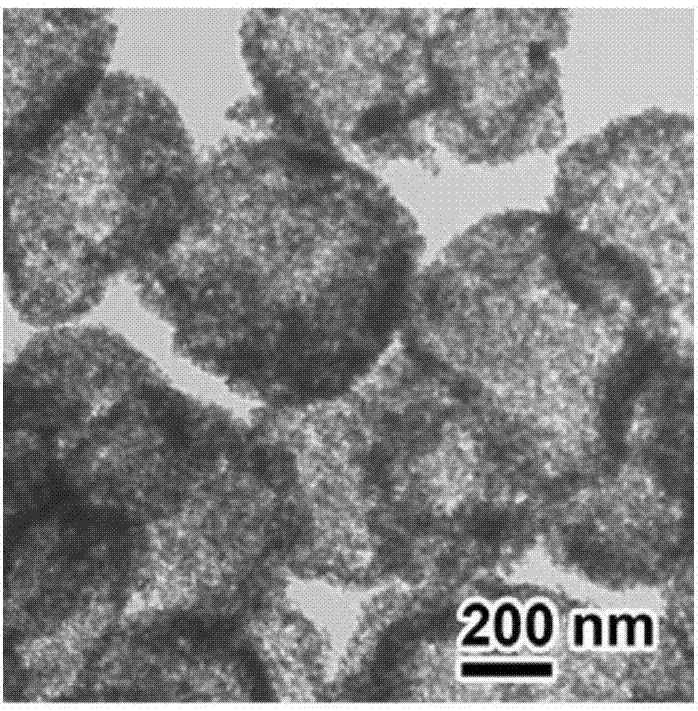

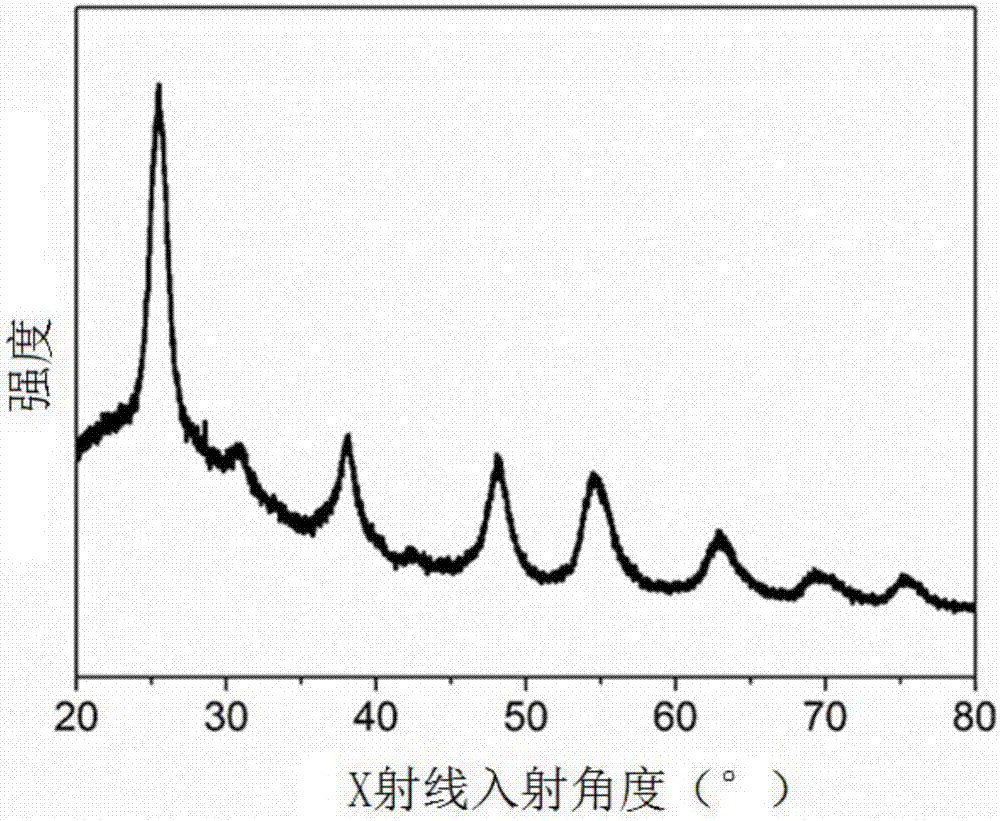

[0040] The invention provides a method for preparing titanium dioxide hollow micro-nanospheres, comprising the following steps: (1) preparing or obtaining porous titanium dioxide micro-nanospheres; (2) loading a linear polymer on the surface of the porous titanium dioxide micro-nanospheres, Obtaining titanium dioxide micronanospheres loaded with linear polymers; (3) coating the surface of the titanium dioxide micronanospheres loaded with linear polymers with a crosslinked polymer; (4) calcining to obtain hollow titanium dioxide micronanospheres.

[0041] The method for preparing titanium dioxide micro-nanospheres in the step (1) can be selected from the photocatalytic surface polymerization method, and the specific steps include: adding tetrabutyl titanate to the alcohol solution of hydroxypropyl cellulose, stirring and reacting, separating the product, washing, The product is dispersed in water to obtain a dispersion liquid of the product, sodium fluoride is added therein, hea...

Embodiment 1

[0049] Titanium dioxide hollow micro-nanospheres were prepared by the following method:

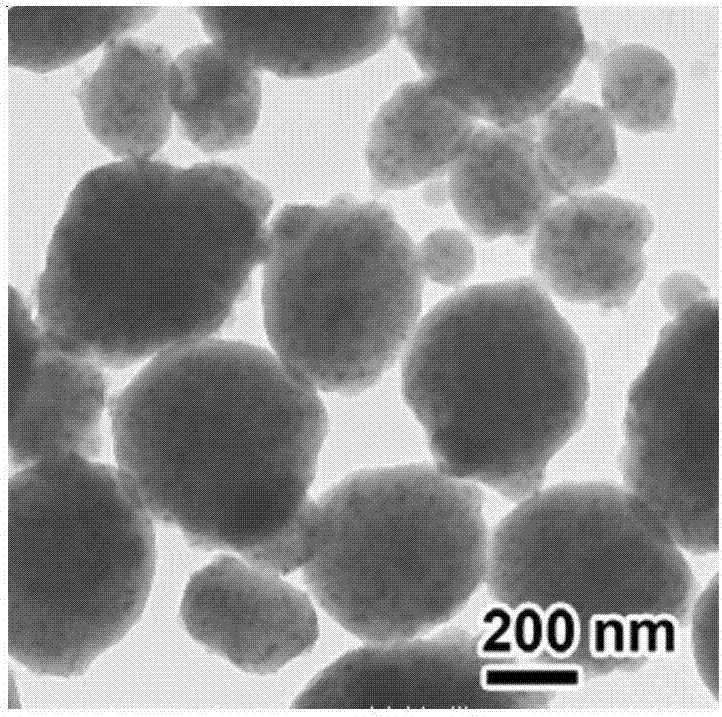

[0050] (1) Preparation of porous titanium dioxide micro-nanospheres

[0051] In this example, titanium dioxide micro-nanospheres were prepared by photocatalytic surface polymerization, and 0.05 g of hydroxypropyl cellulose (HPC) was dissolved in 0.1 mL of H 2 O ethanol 20mL. Stir for 30 minutes to completely dissolve HPC, then add 1 mL of tetrabutyl titanate (TBOT) to the above solution and stir for 15 minutes to stop. After standing for 3 hours, collect the product by centrifugation, wash with ethanol and water, and disperse in 19 mL of water to obtain the product of the dispersion. Add 1mg NaF to the above dispersion and stir for 30min, heat the system to 50°C for 2h, cool to room temperature naturally, wash twice with water and ethanol, and finally disperse in 20mL ethanol solution for later use.

[0052] (2) Preparation of porous titanium dioxide micro-nanospheres modified by MPS ...

Embodiment 2

[0065] Titanium dioxide hollow micro-nanospheres were prepared by the following method:

[0066] (1) Preparation of porous titanium dioxide micro-nanospheres

[0067] In this example, titanium dioxide micro-nanospheres were prepared by photocatalytic surface polymerization, and 0.5 g of hydroxypropyl cellulose (HPC) was dissolved in 5 mL of H 2 O ethanol 50mL. Stir for 30 minutes to completely dissolve HPC, then add 3 mL of tetrabutyl titanate (TBOT) to the above solution and stir for 60 minutes to stop. After standing for 12 hours, collect the product by centrifugation, wash with ethanol and water, and disperse in 50 mL of water to obtain the product of the dispersion. Add 50mg NaF to the above dispersion and stir for 30min, heat the system to 100°C for 2h, cool to room temperature naturally, wash twice with water and ethanol, and finally disperse in 20mL ethanol solution for later use.

[0068] (2) Preparation of porous titanium dioxide micro-nanospheres modified by MPS ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com