Catalyst for catalyzing 5-hydroxymethylfurfural to prepare furan-2,5-dicarbaldehyde in water phase, and preparation method and application of catalyst

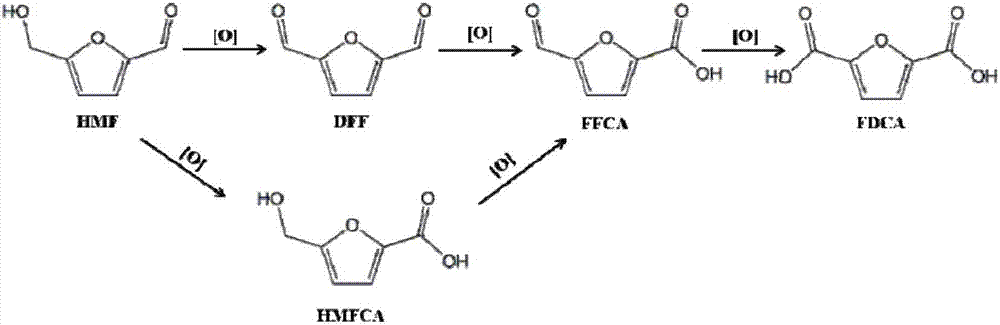

A technology for hydroxymethyl furfural and furandiformaldehyde, which is applied in the field of water-phase catalysis of 5-hydroxymethyl furfural to prepare 2,5-furandiformaldehyde, can solve problems such as environmental damage and formation of acid rain, and achieves easy recovery and production cost. Low, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 0.98g graphene and 1.1mL HAuCl 4 After the aqueous solution (0.01mol / L) is mixed, it is transferred to the hydrothermal reactor, 29mL of deionized water is added, and the reaction is carried out at 150℃ for 5h. After natural cooling, it is washed with water and absolute ethanol three times to obtain a black powder. Dry for 8h at ℃, and finally put it in a tube furnace, H 2 / Ar atmosphere reduced for 5h, where H 2 The volume fraction is 5%, the gas flow rate is 10mL / min, and the reduction temperature is 400°C. 1 g of graphene-supported metal gold (Au2wt%) catalyst can be obtained, wherein the particle size of the gold nanoparticles is 10 nanometers.

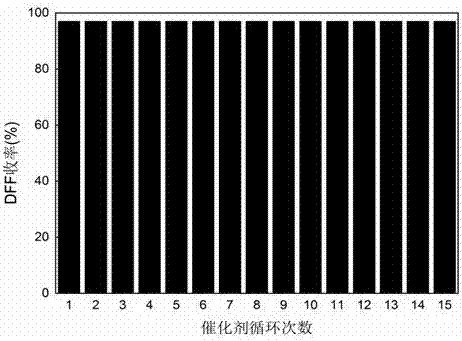

[0024] Add 1g of the above-mentioned catalyst, 1mmol 5-hydroxymethylfurfural and 10mL deionized water into a closed reaction vessel lined with polytetrafluoroethylene. After sealing, it is washed several times with oxygen, and 100mmol of oxygen is introduced, and the temperature is raised under stirring. To 30°C, react a...

Embodiment 2

[0026] Weigh 0.99g silicon carbide and 1.0mL RuCl 3 After the aqueous solution (0.01mol / L) is mixed, it is transferred to the hydrothermal reactor, 88mL of deionized water is added, and the reaction is carried out at 250℃ for 15h. After natural cooling, it is washed with water and absolute ethanol three times to obtain dark green powder. Dry for 12h at 120℃, and finally put it in a tube furnace, H 2 / Ar atmosphere reduced for 12h, where H 2 The volume fraction of is 10%, the gas flow rate is 30mL / min, and the reduction temperature is 600°C. 1g of silicon carbide supported metal ruthenium (Ru1wt%) catalyst can be obtained, wherein the diameter of the ruthenium nanoparticles is 6 nanometers.

[0027] Add 1g of the above catalyst, 0.25mmol 5-hydroxymethylfurfural and 10mL deionized water into a closed reaction vessel lined with polytetrafluoroethylene. After sealing, it is washed several times with oxygen, and 25mmol of oxygen is introduced under stirring. The temperature is increas...

Embodiment 3

[0029] Weigh 0.80g carbon nitride and 5.1mL H 2 PtCl 3 ·6H 2 O and 15.7mL Cu(NO 3 ) 2 After the aqueous solution (0.01mol / L) is mixed, it is transferred to the hydrothermal reactor, 60mL of deionized water is added, and the reaction is carried out at 220°C for 12h. After natural cooling, it is washed with water and absolute ethanol three times to obtain a dark green powder. Dry it at 120℃ for 10h, and finally put it in a tube furnace, H 2 / Ar atmosphere reduced for 5h, where H 2 The volume fraction is 5%, the gas flow rate is 15mL / min, and the reduction temperature is 500°C. 1 g of carbon nitride supported platinum-copper alloy (Pt 10wt%, Cu 10wt%) catalyst can be obtained, wherein the platinum-copper alloy nanoparticles have a particle size of 56 nanometers.

[0030] Add 1g of the above catalyst, 1mmol 5-hydroxymethylfurfural and 10mL deionized water into a closed reaction vessel lined with polytetrafluoroethylene. After sealing, it is washed several times with oxygen, and 10mmol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com