Heat-resistant injection-molded ferrite master batch and preparation method thereof

A ferrite and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant injection ferrite masterbatch and its preparation, can solve the problems of unreachable, magnetic properties and fluidity of pellets that cannot meet the production needs of high-performance products, low performance, etc. problems, to achieve good magnetic properties, easy production, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

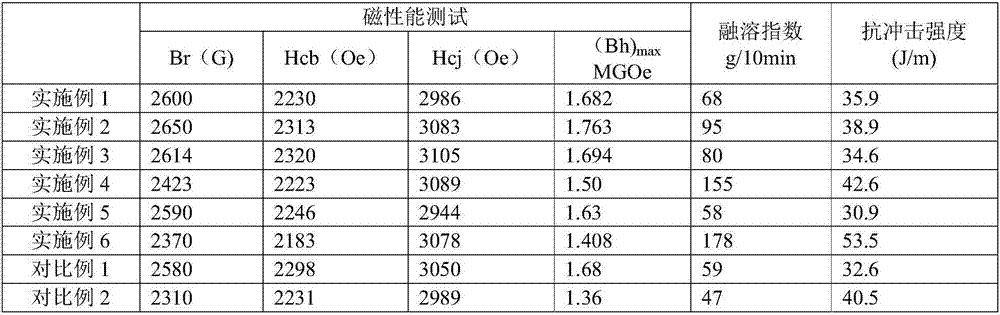

Examples

Embodiment 1

[0031] A high temperature resistant injection molded ferrite masterbatch, which is mainly made of the following raw materials in weight percentage:

[0032] Rare earth magnetic powder 70wt%, polyphenylene sulfide 23.8wt%, polyparaphenylene terephthalamide 2.0wt%, titanate coupling agent 2.0wt%, sodium pyrophosphate 2.0wt%, phospholipid 0.1wt%, paraffin 0.1 wt%.

[0033] A preparation method of high temperature resistant injection molded ferrite masterbatch, comprising the following steps:

[0034] Add dispersant to the magnetic powder and mix evenly, then add surface treatment additives to it for surface treatment, then add polyphenylene sulfide mixed with polyparaphenylene terephthalamide, antioxidant and lubricant and mix evenly, Finally, use a twin-screw granulator to extrude and granulate; wherein the mixing temperature is 80°C, and the granulation temperature is 280°C; the surface treatment additive is mixed with ethanol or isopropanol before adding, and the content of e...

Embodiment 2

[0036] A high temperature resistant injection molded ferrite masterbatch, which is mainly made of the following raw materials in weight percentage:

[0037] Strontium ferrite magnetic powder 85.68wt%, polyphenylene sulfide 13.1wt%, polyparaphenylene terephthalamide 0.05wt%, phosphate coupling agent 0.86wt%, sodium metapolyphosphate 0.17wt%, 4- Hexyl resorcinol 0.07wt%, stearic acid 0.07wt%.

[0038] A preparation method of high temperature resistant injection molded ferrite masterbatch, comprising the following steps:

[0039] Add dispersant to the magnetic powder and mix evenly, then add surface treatment additives to it for surface treatment, then add polyphenylene sulfide mixed with polyparaphenylene terephthalamide, antioxidant and lubricant and mix evenly, Finally, use a twin-screw granulator to extrude and granulate; wherein the mixing temperature is 100°C, and the granulation temperature is 290°C; the surface treatment additive is mixed with ethanol or isopropanol befo...

Embodiment 3

[0041] A high temperature resistant injection molded ferrite masterbatch, which is mainly made of the following raw materials in weight percentage:

[0042] Strontium ferrite magnetic powder 85.8wt%, polyphenylene sulfide 12.95wt%, polyparaphenylene terephthalamide 0.08wt%, silane coupling agent 0.85wt%, sodium metapolyphosphate 0.17wt%, 4-hexyl Resorcinol 0.08wt%, stearic acid 0.07wt%.

[0043] A preparation method of high temperature resistant injection molded ferrite masterbatch, comprising the following steps:

[0044] Add dispersant to the magnetic powder and mix evenly, then add surface treatment additives to it for surface treatment, then add polyphenylene sulfide mixed with polyparaphenylene terephthalamide, antioxidant and lubricant and mix evenly, Finally, use a twin-screw granulator to extrude and granulate; wherein the mixing temperature is 100°C, and the granulation temperature is 300°C; the surface treatment additive is mixed with ethanol or isopropanol before a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com