Trivalent chromium coating and preparation method thereof

A technology of trivalent chromium and coating, applied in the field of trivalent chromium coating and its preparation, can solve the problems of poor resistance to impurities, corrosion of plating bath, dark surface, etc., and achieve good blackening degree, low porosity and dense coating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

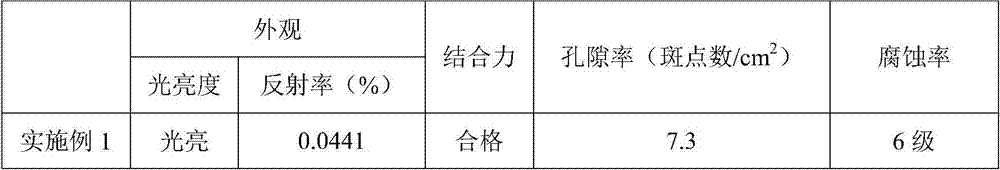

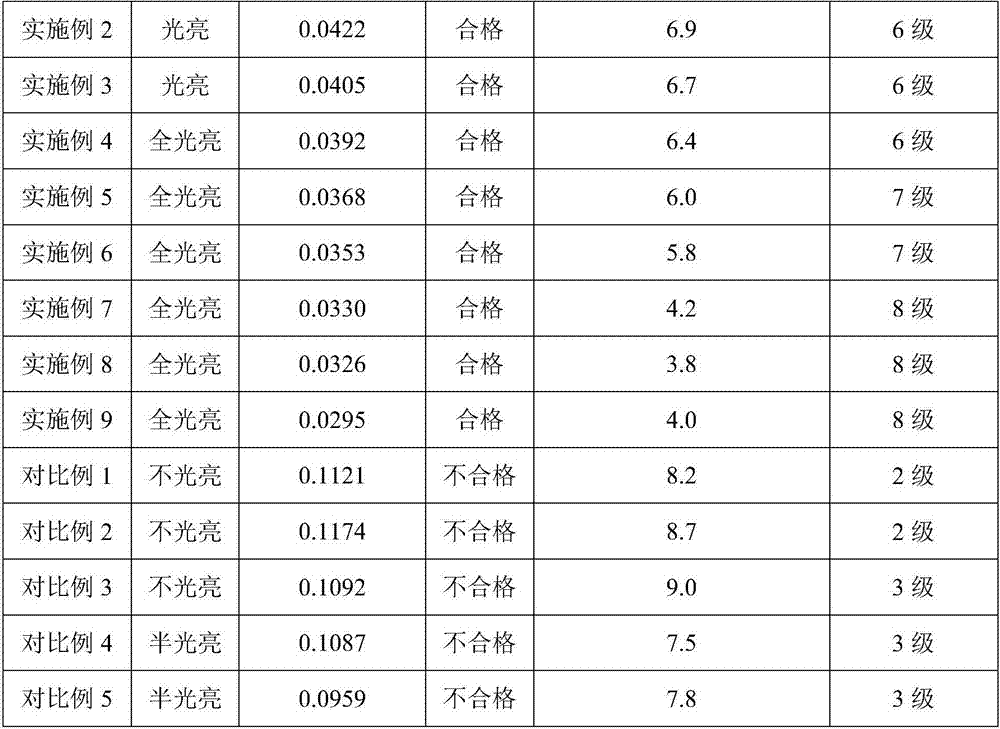

Examples

preparation example Construction

[0027] In order to solve the above technical problems, the first aspect of the present invention provides a method for preparing a trivalent chromium coating, which at least includes the following steps: immersing the substrate in a trivalent chromium electroplating solution, and using the substrate as a cathode for Electroplating, electroplating temperature is 20 ~ 45 ℃, current density is 6A / dm 2 ~25A / dm 2 , the electroplating time is 5 to 30 minutes; the trivalent chromium coating is plated on the substrate; the surface of the substrate includes at least one conductive layer;

[0028] The trivalent chromium electroplating solution at least includes the following components: trivalent water-soluble chromium salt: 15-20 parts by weight; cobalt salt: 12-16 parts by weight; conductive salt: 20-35 parts by weight; complexing agent: 4-6 parts by weight; buffering agent: 7-10 parts by weight; blackening agent: 0.5-1.6 parts by weight; brightener: 0.01-0.5 parts by weight; deioniz...

Embodiment 1

[0089] Embodiment 1 provides a preparation method of a trivalent chromium coating, at least including the following steps: immersing the substrate in a trivalent chromium electroplating solution, electroplating with the substrate as a cathode, the electroplating temperature is 20°C, and the current density 6A / dm 2 , the electroplating time is 5min; the trivalent chromium coating is plated on the substrate; the surface of the substrate contains at least one conductive layer;

[0090] The trivalent chromium electroplating solution at least includes the following components: trivalent water-soluble chromium salt: 15 parts by weight; cobalt salt: 12 parts by weight; conductive salt: 20 parts by weight; complexing agent: 4 parts by weight; buffer : 7 parts by weight; blackening agent: 0.5 parts by weight; brightener: 0.01 parts by weight; deionized water: 100 parts by weight.

[0091] The trivalent water-soluble chromium salt is chromium sulfate; the cobalt salt is cobalt sulfate;...

Embodiment 2

[0100] Embodiment 2 provides a preparation method of a trivalent chromium coating, which at least includes the following steps: immersing the substrate in a trivalent chromium electroplating solution, electroplating with the substrate as a cathode, the electroplating temperature is 20°C, and the current density 6A / dm 2 , the electroplating time is 5min; the trivalent chromium coating is plated on the substrate; the surface of the substrate contains at least one conductive layer;

[0101] The trivalent chromium electroplating solution at least includes the following components: trivalent water-soluble chromium salt: 20 parts by weight; cobalt salt: 16 parts by weight; conductive salt: 35 parts by weight; complexing agent: 6 parts by weight; : 10 parts by weight; blackening agent: 1.6 parts by weight; brightener: 0.5 parts by weight; deionized water: 100 parts by weight.

[0102] The trivalent water-soluble chromium salt is chromium sulfate; the cobalt salt is cobalt sulfate; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com