Papermaking modified calcium carbonate and method for preparing same

A technology of calcium carbonate and light calcium carbonate, which is applied in the field of calcium carbonate, can solve the problems of increasing wastewater treatment volume and treatment cost, weak binding force between calcium carbonate and fiber, and large decline in paper strength performance, so as to achieve good film-forming properties , Improve lubricity and gloss, strong alkali and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

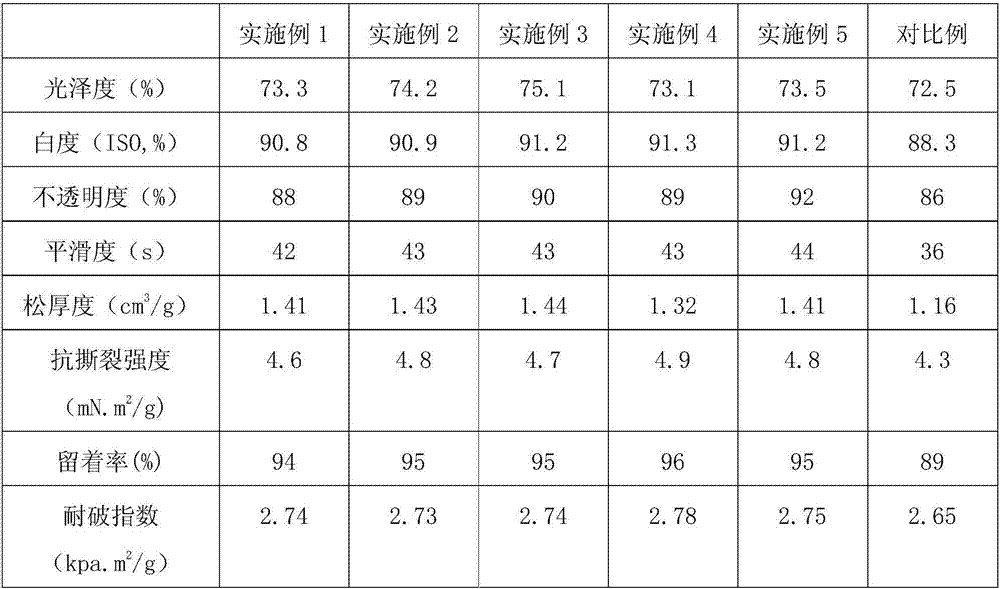

Examples

Embodiment 1

[0025] A modified calcium carbonate used in papermaking, mainly prepared from the following raw materials by weight: 100 parts by weight of light calcium carbonate, 10 parts of bamboo pulp fiber, 30 parts of cationic starch, 1 part of sodium stearate, and 0.01 part of sodium polyacrylate Parts, 1 part of bentonite, 0.1 part of chitosan, 0.01 part of trimethyl phosphate hardener, 0.2 part of antioxidant, 0.5 part of PEO dispersant and 0.5 part of silane coupling agent. Wherein, the antioxidant is prepared by mixing propyl gallate and metasulfite in a weight ratio of 1:2.

[0026] The embodiment of the present invention also provides a method for preparing modified calcium carbonate for papermaking, the method includes the following steps:

[0027] (1) Weigh the above raw materials in parts by weight and set aside;

[0028] (2) Add bamboo pulp fiber to water, heat for 15 minutes while stirring in a water bath at 50°C, then add sodium polyacrylate, bentonite and chitosan, and stir at 3...

Embodiment 2

[0034] A modified calcium carbonate used in papermaking, mainly prepared from the following raw materials by weight: 120 parts by weight of light calcium carbonate, 15 parts of bamboo pulp fiber, 40 parts of cationic starch, 3 parts of sodium stearate, and 0.05 parts of sodium polyacrylate Parts, 3 parts of bentonite, 0.8 parts of chitosan, 0.05 parts of trimethyl phosphate hardener, 0.8 parts of antioxidant, 1.5 parts of PEO dispersant and 1.5 parts of silane coupling agent. Wherein, the antioxidant is prepared by mixing propyl gallate and metasulfite in a weight ratio of 1:5.

[0035] The embodiment of the present invention also provides a method for preparing modified calcium carbonate for papermaking, the method includes the following steps:

[0036] (1) Weigh the above raw materials in parts by weight and set aside;

[0037] (2) Add bamboo pulp fiber to water, heat for 20 minutes while stirring in a 55°C water bath, then add sodium polyacrylate, bentonite and chitosan, and stir...

Embodiment 3

[0043] A modified calcium carbonate used for papermaking, mainly prepared from the following raw materials by weight: 105 parts by weight of light calcium carbonate, 11 parts of bamboo pulp fiber, 32 parts of cationic starch, 1.5 parts of sodium stearate, and 0.02 parts of sodium polyacrylate Parts, 1.5 parts of bentonite, 0.2 parts of chitosan, 0.02 parts of trimethyl phosphate hardener, 0.3 parts of antioxidant, 0.7 parts of PEO dispersant and 0.7 parts of silane coupling agent. Wherein, the antioxidant is prepared by mixing propyl gallate and metasulfite in a weight ratio of 1:3.

[0044] The embodiment of the present invention also provides a method for preparing modified calcium carbonate for papermaking, the method includes the following steps:

[0045] (1) Weigh the above raw materials in parts by weight and set aside;

[0046] (2) Add bamboo pulp fiber to water, heat for 16 min while stirring in a water bath at 51°C, then add sodium polyacrylate, bentonite and chitosan, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com