Environment-friendly oil immersed transformer

A transformer and environmental protection oil technology, applied in the field of transformers, can solve the problems of poor circulation and purification effect, inability to thoroughly clean transformer oil, and dust pollution of the environment, and achieve the goal of isolating external air and water vapor, good environmental protection and energy saving, and reducing environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions will be clearly and completely described below in conjunction with the drawings and embodiments of the present invention. Describe the scheme of the present invention in detail below in conjunction with specific embodiment:

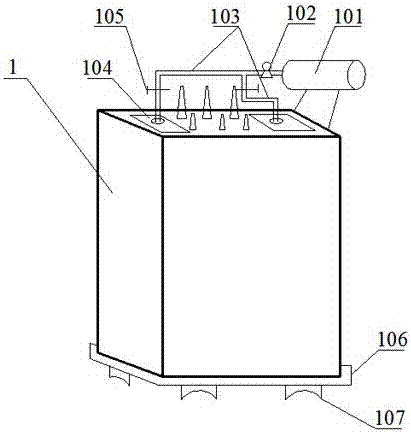

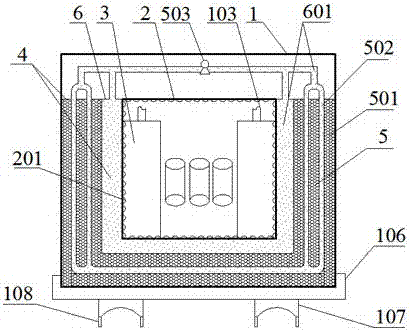

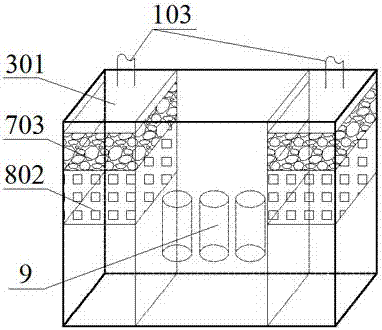

[0032]An environmentally friendly oil-immersed transformer, comprising an oil tank outer shell 1, an oil tank inner shell 2, an iron core located in the center of the oil tank inner shell 2 and a winding 9, located on both sides of the iron core and winding 9 and forming a cavity with the side wall of the oil tank inner shell 2 The oil purification device 3 and the noise reduction device 4 located in the fuel tank and between the shells, the top of the fuel tank shell 1 is provided with an oil conservator 101 and an oil pump 102, and the noise reduction device 4 includes two interlayers, respectively Noise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com