Method of manufacturing inorganic quantum dot light emitting diode device

A quantum dot light-emitting and diode technology, which is used in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of difficult injection of electrons and holes into the light-emitting layer, low exciton recombination efficiency, and high device operating voltage. , to achieve the effect of low preparation difficulty, good charge injection and transfer ability, and stable device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

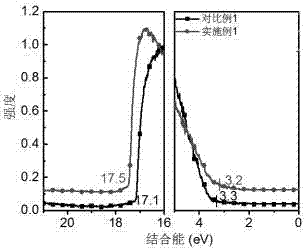

Embodiment 1

[0028] A preparation of an inorganic quantum dot light-emitting diode device, the preparation steps of the method are as follows:

[0029] Step 1: Rinse the ITO transparent conductive glass substrate in deionized water first, then wash it repeatedly with deionized water, acetone, and ethanol three times, and bake it in a clean environment until the water is completely removed;

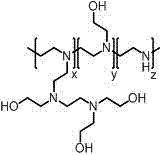

[0030] The second step: PEIE is diluted with ethanol to a concentration of 0.1 wt%, and then coated with PEIE solution on the ITO transparent conductive glass substrate to form a PEIE film layer of about 10 nm;

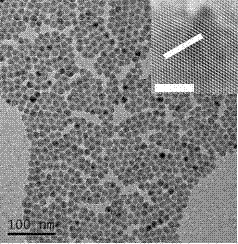

[0031] The third step: PEIE was mixed into the ZnO nanoparticle solution with a doping concentration of 0.1 wt%, and then the mixed solution of ZnO:PEIE was coated on the substrate to form a ZnO:PEIE film layer with a thickness of 60 nm, wherein ZnO The nanoparticle solution is prepared by a common process, which is prepared by the mixed reaction of zinc acetate and tetramethylammonium hydroxi...

Embodiment 2

[0035] The difference between Example 2 and Example 1 is that the concentration of the ethanol solution in the second step is 0.05 wt%, and a PEIE film layer of about 5 nm is formed.

Embodiment 3

[0037] The difference between Example 3 and Example 1 is that the concentration of the mixed solution of ZnO:PEIE in the third step is 0.05 wt%, and the thickness of the film layer is 50 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com