Glass Article

A glass and article technology, applied in the field of glass articles, can solve the problems of lower product characteristics, longer optical path length, lower brightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0217] Hereinafter, examples of the present invention will be described.

[0218] The raw material of each component was prepared so that it might become a target composition, and it melted at 1350 degreeC for 1 hour using the platinum crucible. When melting, 400 g of raw material was added in 3 times every 20 minutes. Next, the obtained molten liquid was heated up to a predetermined temperature of 1450° C. to 1650° C. over 1 hour, and then left to stand for 3 hours. The melting temperature of this second stage is appropriately selected according to the clarity of the glass. Incidentally, in the glasses of Examples 58 to 66, melting was performed while blowing 1 L / min of oxygen into the atmosphere.

[0219] The molten glass is poured onto a preheated carbon mold and shaped into a plate, which is then slowly cooled.

[0220] It should be noted that the raw materials are selected from silica sand, alumina, sodium carbonate and other commonly used glass raw materials. Moreove...

example 1

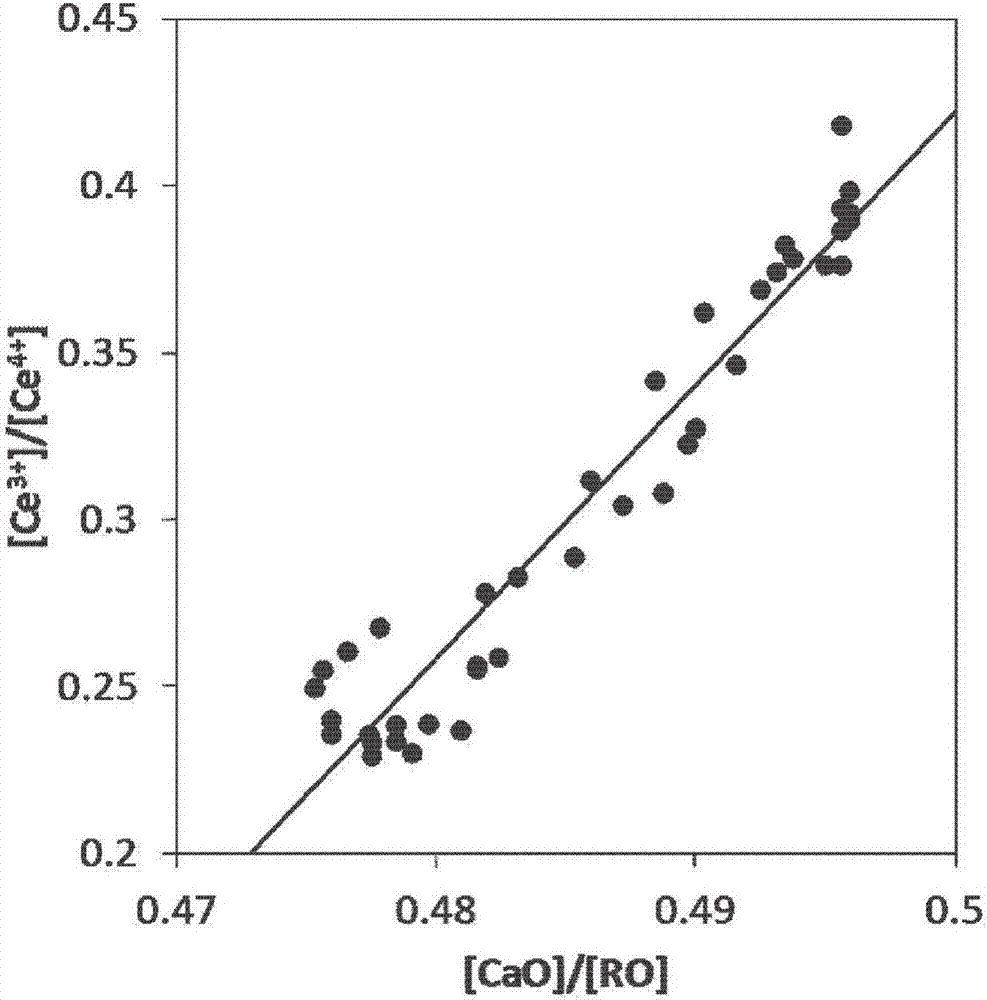

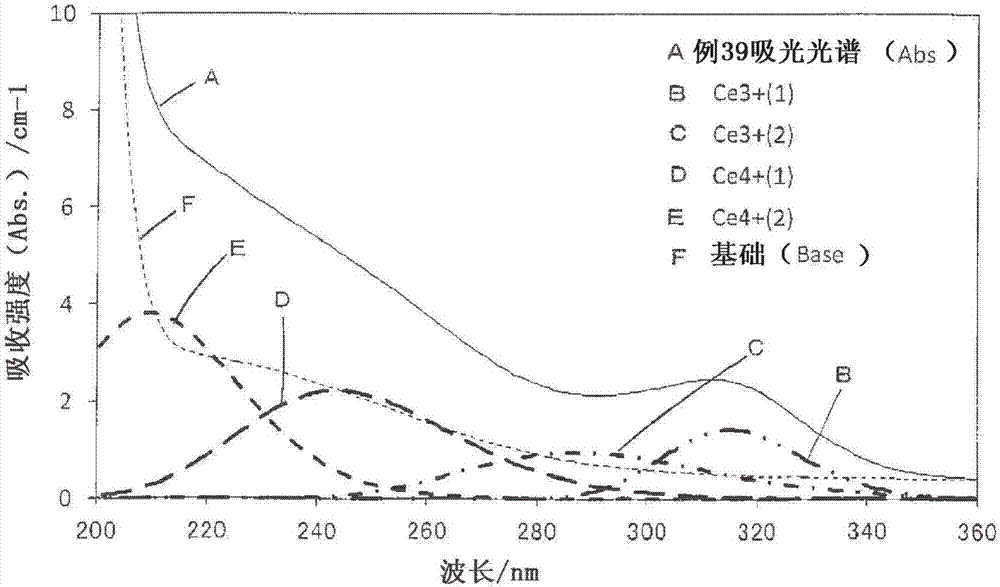

[0237] Table 1 and Table 2 show the glass composition (unit: mass %) of Examples 1 to 20, and the content of iron in the glass in terms of Fe 2 o 3 total iron oxide (t-Fe 2 o 3 ) content (unit: ppm), converted into CeO 2 The content of cerium oxide (unit: ppm), iron redox value (Fe-redox), according to the left side of formula 3 (64×[MgO]+100×[CaO]+127×[SrO]+156×[BaO] ) while the calculated parameter B RO (Denoted as B_RO in the table), and shows that for samples of these glasses the high pressure mercury lamp was used at an illuminance of 45mW / cm 2 Transmittance change at wavelength 400nm and optical path length 1mm before and after irradiation for 30 seconds Δ%T@400nm, transmittance (%) at optical path length 5cm at wavelengths 450nm, 520nm, and 700nm, Ce 3+ / C 4+ . In addition, although not described in the table, each glass contains 6.0 ppm of MnO 2 , 0.5ppm NiO, 0.6ppm Cr 2 o 3 .

[0238] In the table, examples 1 to 16 are examples, and examples 17 to 20 are co...

example 2

[0246] Table 3 and Table 4 show the glass composition (unit: mass %) of Examples 21 to 38, and the content of iron in the glass in terms of Fe 2 o 3 total iron oxide (t-Fe 2 o 3 ) content (unit: ppm), converted into CeO 2 The content of cerium oxide (unit: ppm), iron redox value (Fe-redox), according to the left side of formula 3 (64×[MgO]+100×[CaO]+127×[SrO]+156×[BaO] ) while the calculated parameter B RO (Denoted as B_RO in the table), and shows that for samples of these glasses the high pressure mercury lamp was used at an illuminance of 45mW / cm 2 Transmittance change at wavelength 400nm and optical path length 1mm before and after irradiation for 30 seconds Δ%T@400nm, transmittance (%) at optical path length 5cm at wavelengths 450nm, 520nm, and 700nm, Ce 3+ / C 4+ . In addition, although not described in the table, each glass contains 6.0 ppm of MnO 2 , 0.5ppm NiO, 0.6ppm Cr 2 o 3 .

[0247] In the table, examples 21 to 37 are examples, and example 38 is a compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com