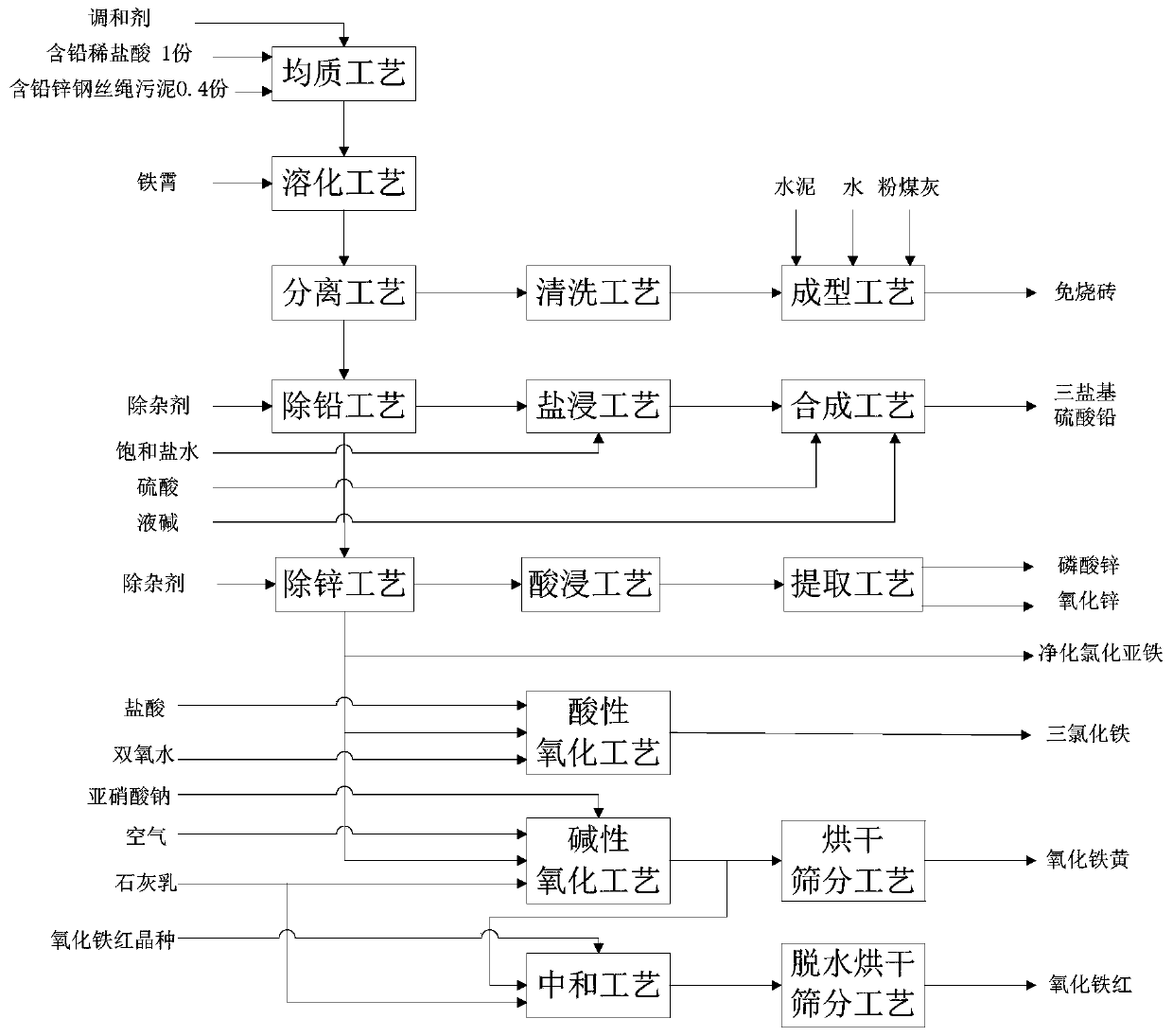

A method for comprehensive treatment of lead-zinc steel wire rope sludge and lead-containing waste hydrochloric acid

A comprehensive treatment, steel wire rope technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of ineffective separation of lead and zinc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Add 10 kg of lead-containing waste hydrochloric acid with a hydrochloric acid mass concentration of 5% and 4 kg of lead-zinc steel wire rope sludge into a 10-cubic homogeneous reaction vessel and mix, wherein the lead ion mass concentration in the lead-containing waste hydrochloric acid is 9860ppm , the mass concentration of iron ions is 11%, the water content of the lead-zinc steel wire rope sludge is 78%, the mass concentration of iron ions is 11%, and the mass concentration of lead ions is 2000ppm. The lead-containing waste hydrochloric acid and the lead-zinc steel wire rope sludge are stirred After uniformity, add a cationic surfactant prepared with hydrochloric acid as a blending agent, and adjust the pH to 0.5 under the regulation of a homogeneous pump. Then, transfer the adjusted mixed material to a 10-cubic glass-lined reactor that can be heated, add iron filings as a regulator, raise the temperature to 95°C and keep it for 120 minutes for extraction, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com