Locust suction trap machine

A locust and centrifugal fan technology, which is applied in the field of locust sucking and catching machines, can solve problems such as difficulty in feeding and discharging materials, high labor intensity, poor safety guarantee, etc., to enhance operational stability and impact load resistance, improve mass transfer efficiency and Methane gas production rate and effect of reducing pollutant discharge load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

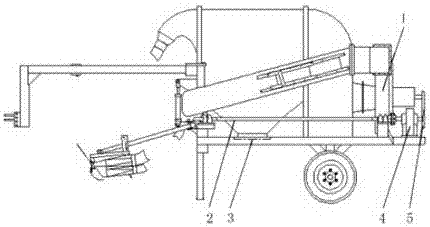

[0008] Such as figure 1 As shown, a locust sucking and catching machine includes a centrifugal fan 1 and a central universal joint transmission shaft 2. The left side of the centrifugal fan 1 is provided with a central universal joint transmission shaft 2, and the middle universal joint transmission shaft 2 bottom is A discharge port 3 is provided, a gearbox 4 is provided on the right side of the centrifugal fan 1, and a V-belt 5 is provided on the right side of the gearbox 4.

[0009] The discharge port 3 adopts a screw output discharge device.

[0010] It works as follows:

[0011] The working process of the grass locust suction machine is to use the power output shaft of the tractor as the power source, through the PTO transmission shaft and the intermediate universal joint transmission shaft 2 to drive the gearbox 4 to increase the speed, and the gearbox 4 transmits the power to the V-belt 5. Centrifugal fan 1: Centrifugal fan 1 generates continuous negative pressure air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com