Mango jam and manufacture method thereof

A production method, mango technology, applied in the functions of food ingredients, food ingredients containing natural extracts, food science, etc., can solve the problems of immaturity, less research, and the development of mango deep processing and utilization backward planting industry, so as to reduce the content of mango , lower blood lipids, and help the body repair tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

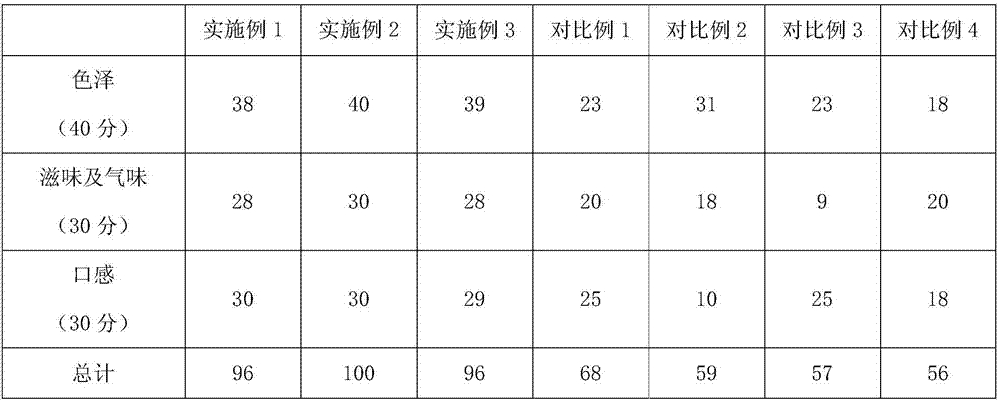

Embodiment 1

[0026] A mango jam, made from the following raw materials in parts by weight: 85 parts of mango, 15 parts of coconut milk, 10 parts of aloe vera, 12 parts of papaya, 5 parts of grapefruit, 5 parts of carambola, 2 parts of loquat, 1 part of konjac powder, lemon 4 parts, 20 parts of rock sugar, 0.3 parts of plant extractant, and appropriate amount of water; wherein, the preparation method of the plant extractant is: collect 10 parts of mulberry leaves, 6 parts of perilla leaves, 2 parts of Polygonatum polygonatum, and 1 part of Schisandra chinensis according to parts by weight ; Cut mulberry leaves, perilla leaves, Polygonatum odoratum into small pieces of 2 cm and mix them with Schisandra chinensis to obtain mixture a, put mixture a into 6 times the mass of cold water and soak for 1 hour, then cook with low heat for 1 hour, filter after cooling, and obtain the filtrate It is a plant extract.

[0027] The preparation method of described mango jam comprises the following steps: ...

Embodiment 2

[0034] A mango jam, made of the following raw materials in parts by weight: 100 parts of mango, 20 parts of coconut milk, 15 parts of aloe vera, 18 parts of papaya, 10 parts of grapefruit, 8 parts of carambola, 5 parts of loquat, 2 parts of konjac powder, lemon 6 parts, 30 parts of rock sugar, 0.5 parts of plant extractant, appropriate amount of water; wherein, the preparation method of said plant extractant is: collect 15 parts of mulberry leaves, 8 parts of perilla leaves, 4 parts of polygonatum polygonatum, and 2 parts of Schisandra chinensis according to parts by weight ; Cut mulberry leaves, perilla leaves, Polygonatum odoratum into 3cm pieces and mix them with Schisandra chinensis to obtain mixture a, put mixture a into cold water with 8 times its mass, soak for 2h, then cook with low heat for 2h, filter after cooling, and obtain the filtrate It is a plant extract.

[0035] The preparation method of described mango jam comprises the following steps:

[0036] (1) Wash th...

Embodiment 3

[0042] A mango jam, made from the following raw materials in parts by weight: 93 parts of mango, 18 parts of coconut milk, 14 parts of aloe, 16 parts of papaya, 8 parts of grapefruit, 7 parts of carambola, 4 parts of loquat, 1.2 parts of konjac powder, lemon 5 parts, 25 parts of rock sugar, 0.4 parts of plant extractant, and appropriate amount of water; wherein, the preparation method of said plant extractant is: collect 12 parts of mulberry leaves, 7 parts of perilla leaves, 3 parts of polygonatum polygonatum, and 1.5 parts of Schisandra chinensis according to parts by weight ;Cut mulberry leaves, perilla leaves, Polygonatum odoratum into small pieces of 2-3cm and mix them with Schisandra chinensis to obtain mixture a, put mixture a into cold water 7 times its mass and soak for 1.5h, then cook with low heat for 1.2h, after cooling Filtration, the resulting filtrate is the plant extract.

[0043] The preparation method of described mango jam comprises the following steps:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com