Carbon-coated metal nanocube material and its preparation method

A metal nano-cube technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems affecting the thickness and regularity of thin carbon layers, etc. Achieve the effect of controllable shell thickness, simple and easy method, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

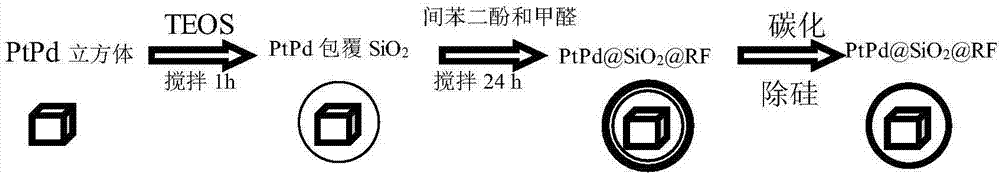

[0033] The present invention also provides a method for preparing the above-mentioned carbon-coated metal nanocube material, comprising:

[0034] S1) mixing metal nanocubes and organosilicate in an alcohol solvent, then mixing and reacting with an alkaline solution, adding phenolic compounds and aldehyde compounds, mixing and reacting, and calcining to obtain carbon spheres;

[0035] S2) Corroding the carbon spheres with HF solution or hot lye to obtain carbon-coated metal nanocube materials.

[0036] The present invention coats silicon dioxide and phenolic resin on the surface of metal nanocubes in a solution in one step, and then calcines to obtain metal nanocubes coated with silicon dioxide and carbon layers, and finally uses an acid solution to remove the carbon dioxide inside the carbon layer. Silicon oxide is etched and removed to obtain a carbon-coated metal nanocube material. This method is simple and easy, and the thickness of the hollow carbon sphere shell is control...

Embodiment 1

[0052] 1.1 Synthesis of PtPd cubes. 1ml of K with a concentration of 20mmol / l 2 PtCl 4 solution and 1ml of Na at a concentration of 20mmol / l 2 PdCl 4 The solution was added to a 25ml polytetrafluoroethylene liner, followed by a solution of 0.075g NaI, 0.16g polyvinylpyrrolidone (PVP) and 10ml dimethylformamide (DMF). The mixed solution was ultrasonicated for half an hour, and the liner was added into the reaction kettle to react at 130°C for 5 hours. After cooling to room temperature, the sample was centrifuged at 10,000 rpm (acetone was used as a precipitating agent), washed and dispersed in a mixed solution of 1 ml of water and ethanol (1:1) for use.

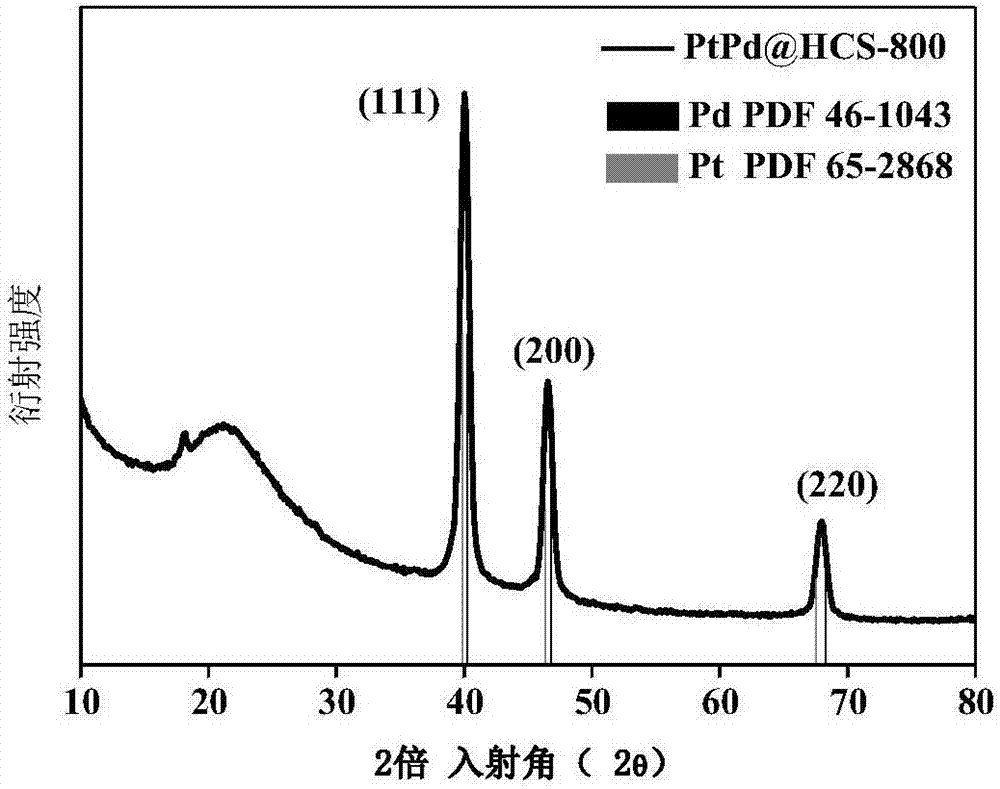

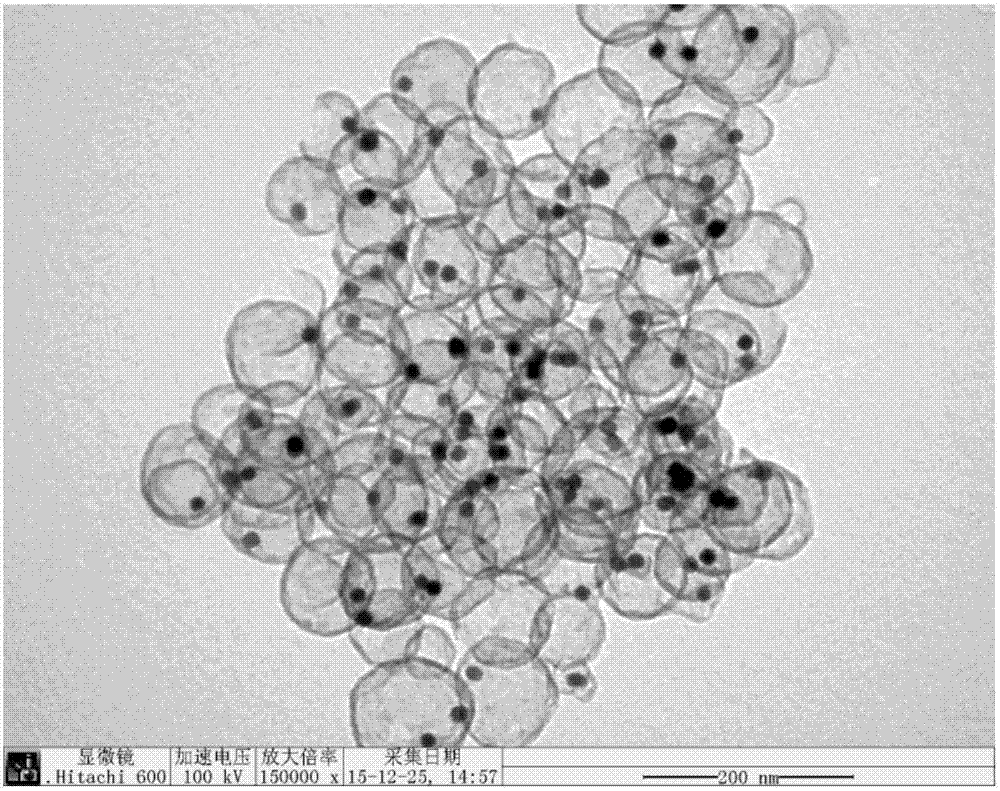

[0053] 1.2 Synthesis of carbon-coated metal nanocube materials. Add 0.5ml of PtPd solution into 7.5ml of ethanol solution, and ultrasonicate for 10min. Add 0.1ml tetraethyl orthosilicate (TEOS) into the above solution and sonicate for 10min. Add the mixed solution into a 50ml round bottom flask containing 5ml ethanol, 1...

Embodiment 2

[0062] 2.1 Synthesis of PtPd cubes. 1ml of K with a concentration of 20mmol / l 2 PtCl 4 solution and 1ml of Na at a concentration of 20mmol / l 2 PdCl 4 The solution was added to a 25ml polytetrafluoroethylene liner, followed by 0.075g NaI, 0.16g PVP and 10ml dimethylformamide (DMF) solution. The mixed solution was ultrasonicated for half an hour, and the liner was added into the reaction kettle to react at 130°C for 5 hours. After cooling to room temperature, the sample was centrifuged at 10,000 rpm (acetone was used as a precipitating agent), washed and dispersed in a mixed solution of 1 ml of water and ethanol (1:1) for use.

[0063] 2.2 Synthesis of carbon-coated metal nanocube materials. Add 0.5ml of PtPd solution into 7.5ml of ethanol solution, and ultrasonicate for 10min. Add 0.1ml TEOS to the above solution and sonicate for 10min. Add the mixed solution into a 50ml round bottom flask containing 5ml ethanol, 1.5ml water and 0.5ml ammonia water, and stir at room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com