Aperture-adjustable insoluble alginate-based supercapacitor activated carbon and one-step carbonization preparation method

A technology of alginate and supercapacitor, applied in chemical instruments and methods, hybrid capacitor electrodes, inorganic chemistry, etc., can solve the problems of single product structure, low capacitance performance, low manufacturing cost, etc., and achieve simple operation and high specific capacitance , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] An insoluble alginate-based activated carbon material for an adjustable aperture supercapacitor and a one-step carbonization preparation method thereof, comprising the following steps:

[0039] The first step, raw material preparation: soak seaweed, wash, crush, then enzymatically hydrolyze solid-liquid separation, add sodium carbonate and water for transformation, extract alginic acid, remove impurities, and dry; commercially available alginic acid can also be used directly.

[0040] The second step is the preparation of the precursor: the obtained alginic acid is configured as a solution, and a certain concentration of CaCl is added 2 / CuCl 2 / ZnCl 2 The aqueous solution is fully stirred to prepare the calcium alginate / copper / zinc precursor. Finally, the obtained samples were fully washed and dried in an oven.

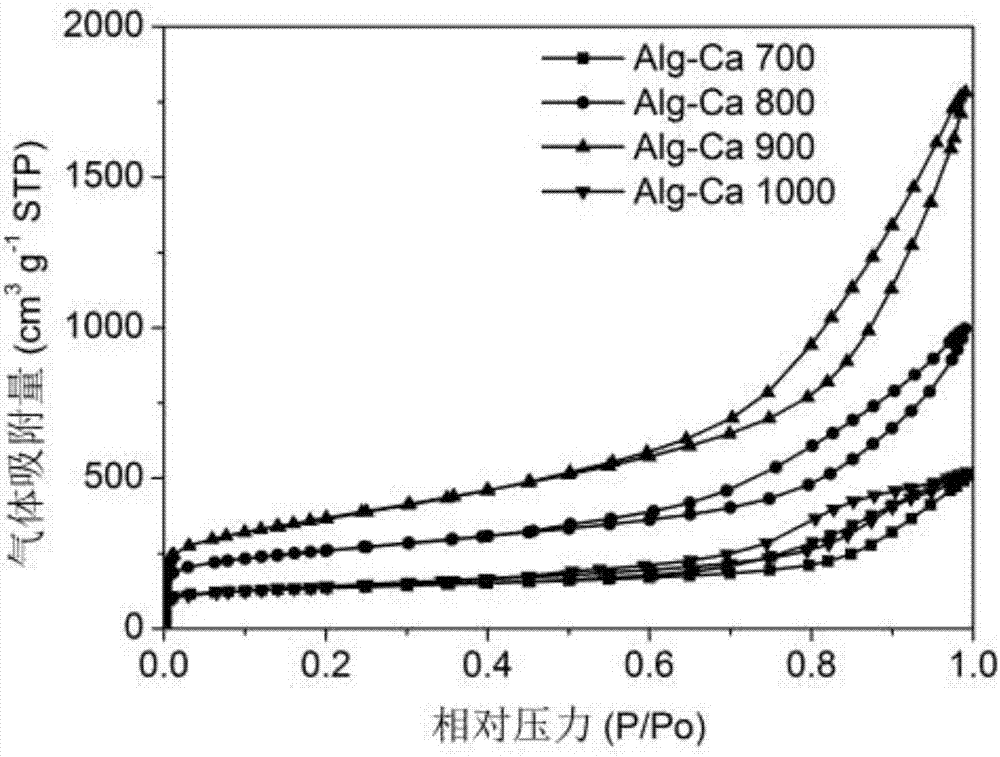

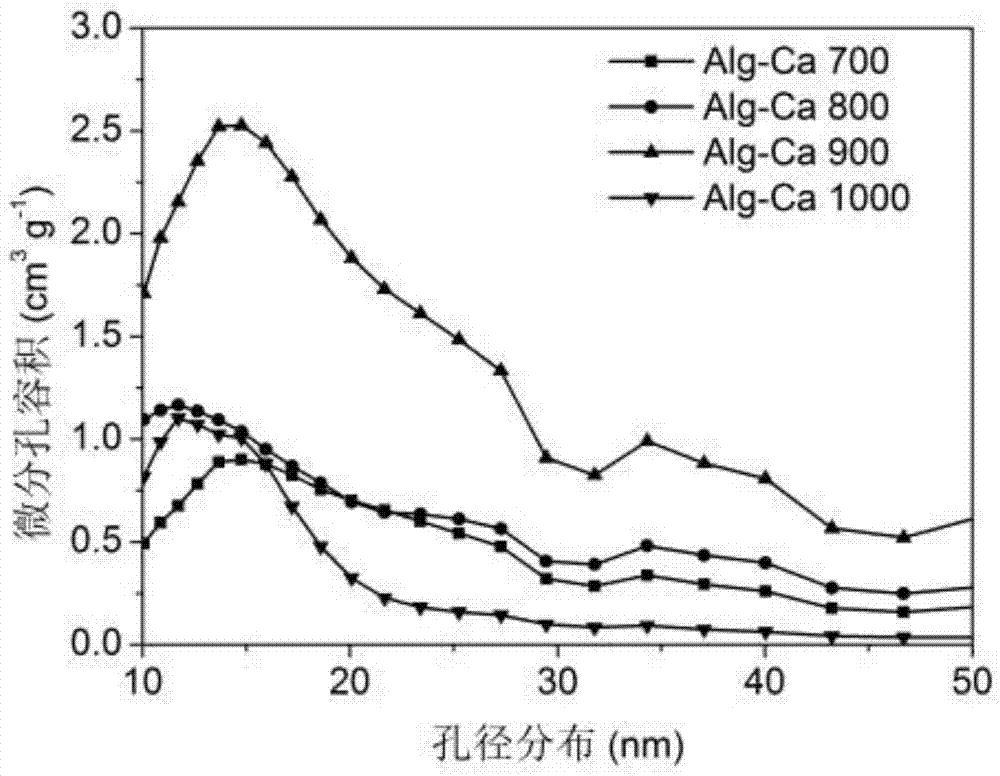

[0041] The third step, carbonization: put the obtained precursor in a quartz boat, put it into a tube furnace, and pass nitrogen gas. Raise the temperatur...

Embodiment 1

[0047] (1) Raw material preparation: soak seaweed, wash, crush, enzymatically hydrolyze solid-liquid separation, add sodium carbonate and water for transformation, extract alginic acid, remove impurities, and dry; add 1%wt CaCl to the obtained alginic acid 2 Thorough stirring is carried out to prepare calcium alginate divalent chelated metal insoluble alginate precursor. Finally, the obtained samples were fully washed and dried in an oven.

[0048] (2) Carbonization: put calcium alginate in a quartz boat and put it into a tube furnace, feed nitrogen gas at a flow rate of 1L / min, raise the temperature from room temperature to 700°C at a heating rate of 10°C / min, keep it for 60min, and cool down naturally to room temperature.

[0049] (3) After the one-step carbonization is completed, the cooled activated carbon sample is washed with hydrochloric acid aqueous solution with a volume ratio of 1:9, then washed with deionized water for 2-4 times, and finally placed in an oven to dr...

Embodiment 2

[0051] (1) Preparation of raw materials: soak seaweed, wash, crush, enzymatically hydrolyze solid-liquid separation, add sodium carbonate and water for transformation, extract alginic acid, remove impurities, and dry; add 5% wt of CuCl to the obtained alginic acid 2 Thorough stirring is carried out to prepare calcium alginate divalent chelated metal insoluble alginate precursor. Finally, the obtained samples were fully washed and dried in an oven.

[0052] (2) Carbonization: Put copper alginate in a quartz boat and put it into a tube furnace, feed nitrogen gas at a flow rate of 1L / min, raise the temperature from room temperature to 800°C at a heating rate of 10°C / min, keep it for 60min, and cool down naturally to room temperature.

[0053] (3) After the one-step carbonization is completed, the cooled activated carbon sample is washed with 1+9 hydrochloric acid, then washed 2-4 times with deionized water, and finally placed in an oven for drying, cooling, and grinding to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com