Preparation method of magnesium oxide board

A technology of glass magnesium board and preparation steps, which is applied in the field of building decoration materials, can solve the problems of incomplete component reaction, easy moisture absorption, product deformation, etc., and achieve the effects of improving mechanical strength, avoiding deformation, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

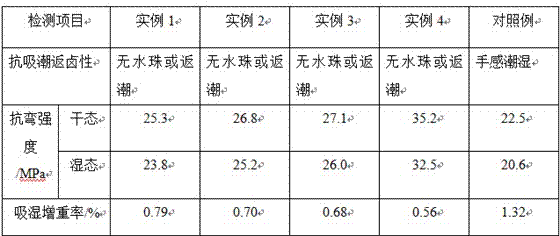

Examples

example 1

[0021] In parts by weight, 60 parts of lightly burned powder, 300 parts of 8% hydrochloric acid by mass fraction, and 10 parts of polyethylene glycol were successively added to the reactor, and stirred at a constant temperature at a temperature of 45°C and a speed of 400r / min. After reacting for 2 hours, filter to obtain the filtrate; in parts by weight, add 20 parts of lightly burned powder, 20 parts of filtrate, and 4 parts of magnesium chloride hexahydrate in the mixer, and stir and mix for 30 minutes at a speed of 300 r / min. , to obtain a slurry; a layer of non-woven fabric is laid on the bottom of the mold, and a layer of glass fiber cloth is laid on the surface of the non-woven fabric, and then the slurry is poured into the mold and roll-formed to obtain a wet billet, and then on the surface of the wet billet Lay a layer of glass fiber cloth, and lay a layer of non-woven fabric on the surface of the glass fiber cloth, then dry it naturally for 3 days at room temperature, ...

example 2

[0023] In parts by weight, take 10 parts of rice husk, 10 parts of quicklime, and 20 parts of water successively, pour them into a glass jar, stir and mix with a glass rod for 15 minutes, seal the glass jar and let it stand for 15 days, filter to obtain a filter cake, It is the mixed wet material of rice husk and lime; in parts by weight, 20 parts of lightly burned powder, 20 parts of water, 20 parts of magnesium chloride hexahydrate, and 3 parts of mixed wet material of rice husk and lime are added successively in the mixer. Under the condition of 300r / min, stir and mix for 30 minutes to obtain the slurry; lay a layer of non-woven fabric on the bottom of the mold, and lay a layer of glass fiber cloth on the surface of the non-woven fabric, then pour the slurry into the mold, roll forming, The wet billet was obtained, and then a layer of glass fiber cloth was laid on the surface of the wet billet, and a layer of non-woven fabric was laid on the surface of the glass fiber cloth,...

example 3

[0025]In parts by weight, take 10 parts of rice husks, 10 parts of quicklime, and 20 parts of water in turn, pour them into a glass jar, stir and mix with a glass rod for 15 minutes, seal the glass jar and let stand for 15 days, filter to obtain a filter cake, That is, rice husk lime mixed wet material; in parts by weight, add 60 parts of light calcined powder, 300 parts by mass of 8% hydrochloric acid, 10 parts of polyethylene glycol in the reaction kettle in turn, at a temperature of 45 ℃, rotating speed Under the condition of 400r / min, after constant temperature stirring reaction for 2h, filter to obtain filtrate; in parts by weight, add 20 parts of light calcined powder, 20 parts of filtrate, 4 parts of magnesium chloride hexahydrate, 3 parts of rice into the mixer in turn Shell lime mixed with wet material, under the condition of rotating speed of 300r / min, stirring and mixing for 30min to obtain slurry; lay a layer of non-woven fabric at the bottom of the mold, and lay a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com