Calcium sulfate whisker-nanometer zinc oxide composite material and its preparation method and application

A calcium sulfate whisker and nano-zinc oxide technology, applied in the field of composite materials, can solve the problems of easy static electricity, limited nano-effects, large specific surface area, etc., and achieve the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

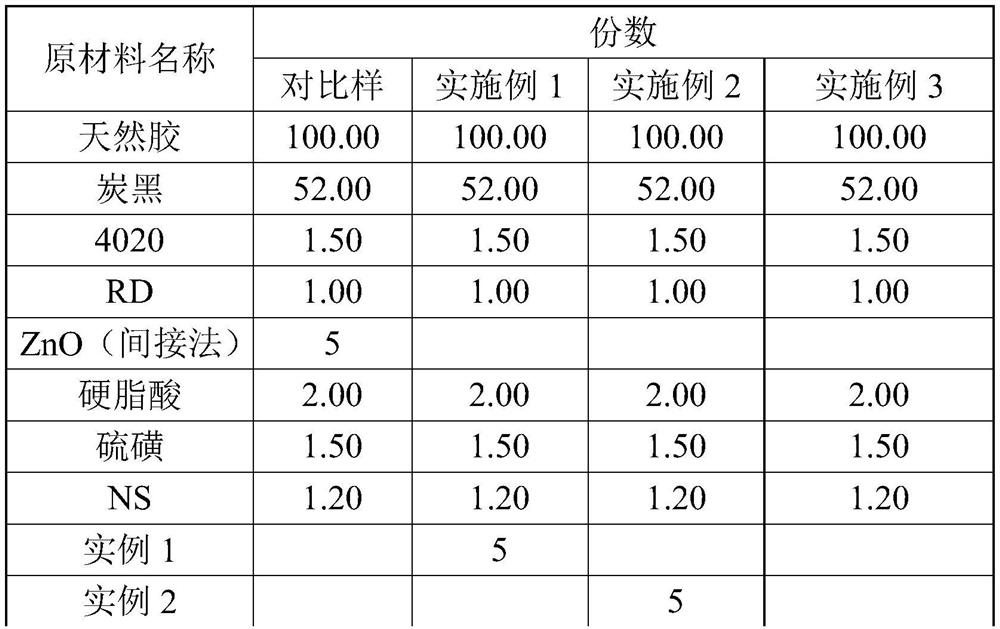

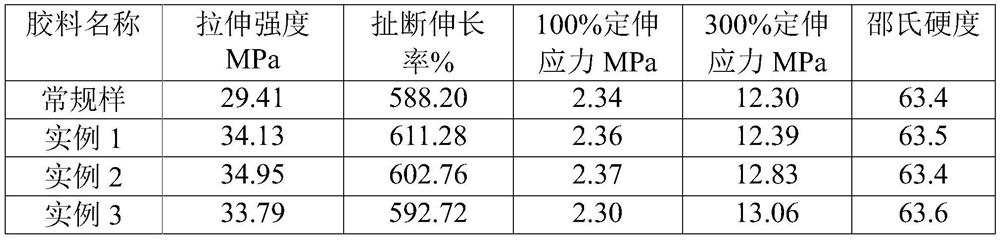

Examples

Embodiment 1

[0044] This embodiment provides a preparation method of calcium sulfate whisker-nanometer zinc oxide composite material, the specific steps are:

[0045] (1) under constant stirring state, 75.4g zinc sulfate is dissolved in a certain amount of water, is made into about 25% transparent solution;

[0046] (2) Under constant stirring, dissolve 35.4g of calcium hydroxide in a certain amount of water to make a white slurry of about 25%, and add 0.3g of sodium dodecylbenzenesulfonate and 1g of magnesium sulfate powder to the white slurry .

[0047] (3) Under constant stirring, the transparent solution of zinc sulfate prepared in step (1) is slowly added to the calcium hydroxide slurry obtained in step (2), and zinc sulfate and calcium hydroxide react to form a white Precipitation of calcium sulfate and zinc hydroxide, control the pH value of the final solution to 10, continue to stir and react at a speed of 600r / min for 60min to obtain a mixed slurry of calcium sulfate and zinc hyd...

Embodiment 2

[0052] This embodiment provides a preparation method of calcium sulfate whisker-nanometer zinc oxide composite material, the specific steps are:

[0053] (1) under constant stirring state, 134.3g zinc sulfate heptahydrate is dissolved in a certain amount of water, is made into about 25% transparent solution;

[0054] (2) Under constant stirring, dissolve 35.4g of calcium hydroxide in a certain amount of water to form a white slurry of about 25%, and add 0.2g of sodium dodecylsulfonate and 0.2g of polyethylene glycol to the white slurry. Glycol 2000 and 2 g of magnesium nitrate powder.

[0055] (3) Under constant stirring, the transparent solution of zinc sulfate prepared in step (1) is slowly added to the calcium hydroxide slurry obtained in step (2), and zinc sulfate and calcium hydroxide react to form a white Precipitation of calcium sulfate and zinc hydroxide, control the pH value of the final solution to 10, continue to stir and react at a speed of 600r / min for 60min to o...

Embodiment 3

[0060] This embodiment provides a preparation method of calcium sulfate whisker-nanometer zinc oxide composite material, the specific steps are:

[0061] (1) Under constant stirring, 85.9g of zinc sulfate monohydrate is dissolved in a certain amount of water to form a transparent solution of about 25%;

[0062] (2) Under constant stirring, dissolve 35.4g of calcium hydroxide in a certain amount of water to form a white slurry of about 25%, and add 0.4g of sodium polyacrylate and 2g of nanometer zinc oxide powder to the white slurry.

[0063] (3) Under constant stirring, the transparent solution of zinc sulfate prepared in step (1) is slowly added to the calcium hydroxide slurry obtained in step (2), and zinc sulfate and calcium hydroxide react to form a white Precipitation of calcium sulfate and zinc hydroxide, control the pH value of the final solution to 10, continue to stir and react at a speed of 360r / min for 30min to obtain a mixed slurry of calcium sulfate and zinc hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com