A kind of tetraacicular zinc oxide whisker modified polyurethane resin coating and preparation method thereof

A technology of four-needle zinc oxide and polyurethane resin, which is applied in the field of coatings, can solve problems such as cracking of paint films, poor compatibility, and low surface energy, and achieve the effects of reducing surface energy, improving water resistance, and improving the degree of microphase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

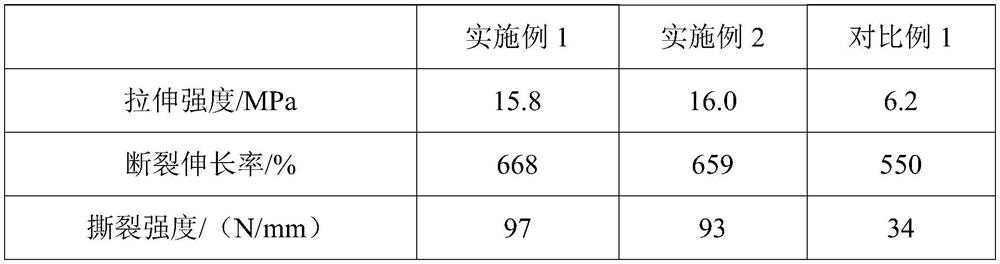

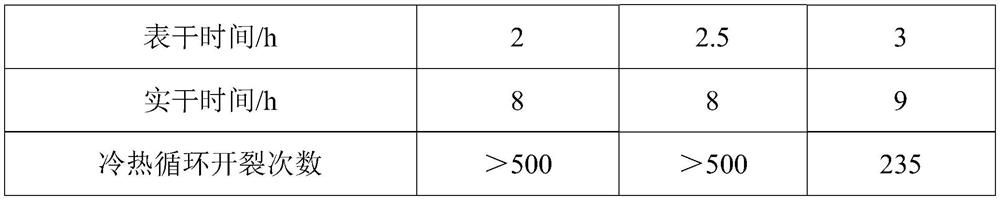

Examples

Embodiment 1

[0025] A four-needle zinc oxide whisker modified polyurethane resin coating, prepared from the following raw materials in parts by weight: 25 parts of polyether polyol, 4 parts of dimethylol propionic acid, 45 parts of isophorone diisocyanate , 12 parts of toluene-2,4-diisocyanate, 0.6 part of dibutyltin dilaurate, 2 parts of dimethylaminoethanol, 4 parts of hydrogenated modified castor oil, polyacrylate pre-coated tetrapod-shaped zinc oxide crystal 15 parts of whiskers, 3 parts of trimethylolpropane, 5 parts of butyl acetate, 12 parts of ethanol, 4 parts of anti-sedimentation agent, nano-Al 2 o 3 20 parts, 140 parts of water.

[0026] Among them, the anti-settling agent is obtained by mixing modified organic bentonite and fumed silica at a mass ratio of 1:1.

[0027] The preparation method of polyacrylate pre-coated tetraacicular zinc oxide whiskers is as follows:

[0028] Mix acrylic acid and butyl acrylate with 12% of the total mass of mixed monomers with a mass ratio of...

Embodiment 2

[0035] A four-needle zinc oxide whisker modified polyurethane resin coating, prepared from the following raw materials in parts by weight: 30 parts of polyether polyol, 5 parts of dimethylol propionic acid, 50 parts of isophorone diisocyanate , 15 parts of toluene-2,4-diisocyanate, 0.2 parts of dibutyltin dilaurate, 3 parts of dimethylaminoethanol, 4 parts of hydrogenated modified castor oil, polyacrylate pre-coated tetrapod zinc oxide crystal 20 parts of whiskers, 3 parts of trimethylolpropane, 6 parts of butyl acetate, 20 parts of ethanol, 3 parts of anti-sedimentation agent, nano Fe 2 o 3 25 parts, 150 parts of water.

[0036] Among them, the anti-settling agent is obtained by mixing modified organic bentonite and fumed silica at a mass ratio of 1:1.

[0037] The preparation method of polyacrylate pre-coated tetraacicular zinc oxide whiskers is as follows:

[0038] Mix acrylic acid and butyl acrylate with 20% of the total mass of mixed monomers with a mass ratio of 4:1, ...

Embodiment 3

[0045] A four-needle zinc oxide whisker modified polyurethane resin coating, prepared from the following raw materials in parts by weight: 20 parts of polyether polyol, 3 parts of dimethylol propionic acid, 40 parts of isophorone diisocyanate , 10 parts of toluene-2,4-diisocyanate, 0.1 part of dibutyltin dilaurate, 1 part of dimethylaminoethanol, 2 parts of hydrogenated modified castor oil, polyacrylate pre-coated tetraacicular zinc oxide crystal 10 parts of whiskers, 1 part of trimethylolpropane, 5 parts of butyl acetate, 10 parts of ethanol, 1 part of anti-sedimentation agent, nano-TiO 2 20 parts, 120 parts of water.

[0046] Among them, the anti-settling agent is obtained by mixing modified organic bentonite and fumed silica at a mass ratio of 1:1.

[0047] The preparation method of polyacrylate pre-coated tetraacicular zinc oxide whiskers is as follows:

[0048] Mix acrylic acid and butyl acrylate with 10% of the total mass of mixed monomers with a mass ratio of 4:1, OP-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com