Acidity and lipase double-sensitive nano-container and preparation method thereof

A dual-sensitivity, nano-container technology, applied in the field of materials, can solve the problems of limiting the application of nano-containers, low sensitivity, long response time of stimulus sources, etc., and achieve the effect of improving sensitivity and application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

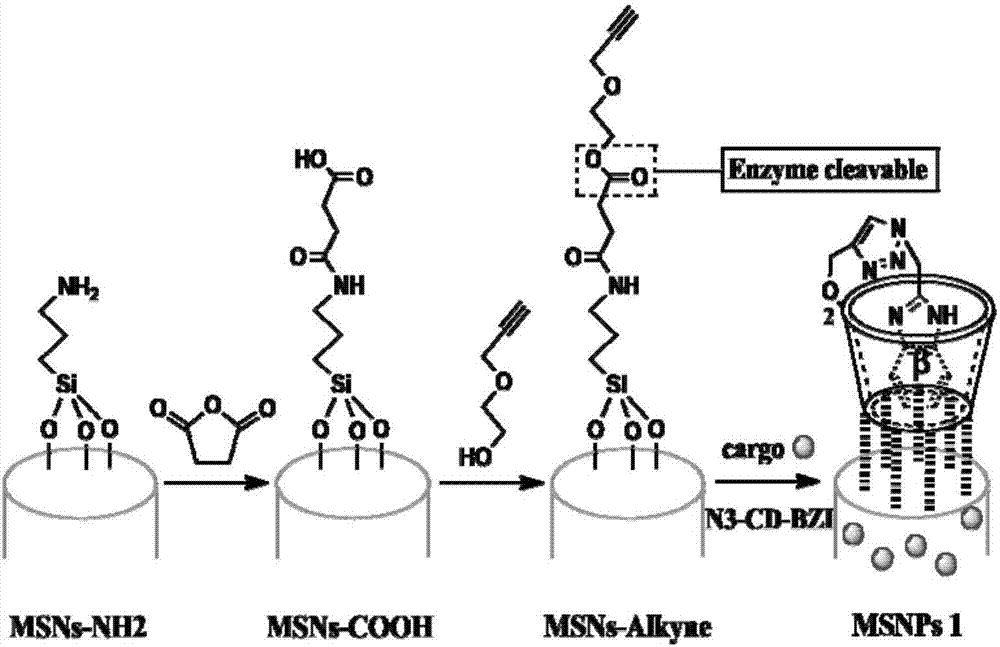

[0028] The preparation method of acid and lipase double sensitive nano container, the steps are as follows:

[0029] 1. Preparation of Mesoporous Silica Microspheres MCM-41

[0030] Cetyltrimethylammonium bromide (CTAB, 0.5g), NaOH solution (2mol / L, 1.75mL) and H 2 O (240 mL) was mixed and stirred at 80 °C for 30 min. Ethyl orthosilicate (TEOS, 2.5 mL) was added dropwise, and a white precipitate was formed after thorough stirring for 10 min. Stir at 80°C for 2h, filter while hot, wash the product thoroughly with water and methanol, and dry it in vacuum at 90°C.

[0031] Weigh 0.3g of dry solid, ultrasonically disperse in a mixed solution of isopropanol (60mL) and concentrated hydrochloric acid (3mL), heat to reflux for 6h, centrifuge, wash thoroughly with water and methanol, and dry under vacuum at 90°C to obtain mesoporous silica Microspheres (MCM-41).

[0032] 2. Surface modification of mesoporous silica

[0033] The dried MCM-41 (200mg) was ultrasonically dispersed in ...

Embodiment 2

[0046] The preparation method of acid and lipase double sensitive nano container, the steps are as follows:

[0047] 1. Preparation of Mesoporous Silica Microspheres MCM-41

[0048] Cetyltrimethylammonium bromide (CTAB, 0.5g), NaOH solution (2mol / L, 1.75mL) and H 2 O (240 mL) was mixed and stirred at 80 °C for 30 min. Ethyl orthosilicate (TEOS, 2.5 mL) was added dropwise, and a white precipitate was formed after thorough stirring for 10 min. Stir at 80°C for 2h, filter while hot, wash the product thoroughly with water and methanol, and dry it in vacuum at 90°C.

[0049] Weigh 0.3g of dry solid, ultrasonically disperse in a mixed solution of isopropanol (60mL) and concentrated hydrochloric acid (3mL), heat to reflux for 6h, centrifuge, wash thoroughly with water and methanol, and dry under vacuum at 90°C to obtain mesoporous silica Microspheres (MCM-41).

[0050] 2. Surface modification of mesoporous silica

[0051] The dried MCM-41 (200mg) was ultrasonically dispersed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com