Preparation method of toughened carbon fiber resin matrix composite

A carbon fiber resin-based, composite material technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of limited application development, insufficient strength of carbon fiber resin-based composite materials, and insufficient resin penetration. Significant improvement in interlaminar fracture toughness, good application prospects, and the effect of improving flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Put 19g of PES powder into a beaker, add dimethyl sulfoxide 4 times the mass of PES, stir at 60°C until uniform, then add 1g of E51 epoxy resin, stir at 30°C to obtain a mixed solution, 30°C Degassing treatment in an oven at ℃ for later use.

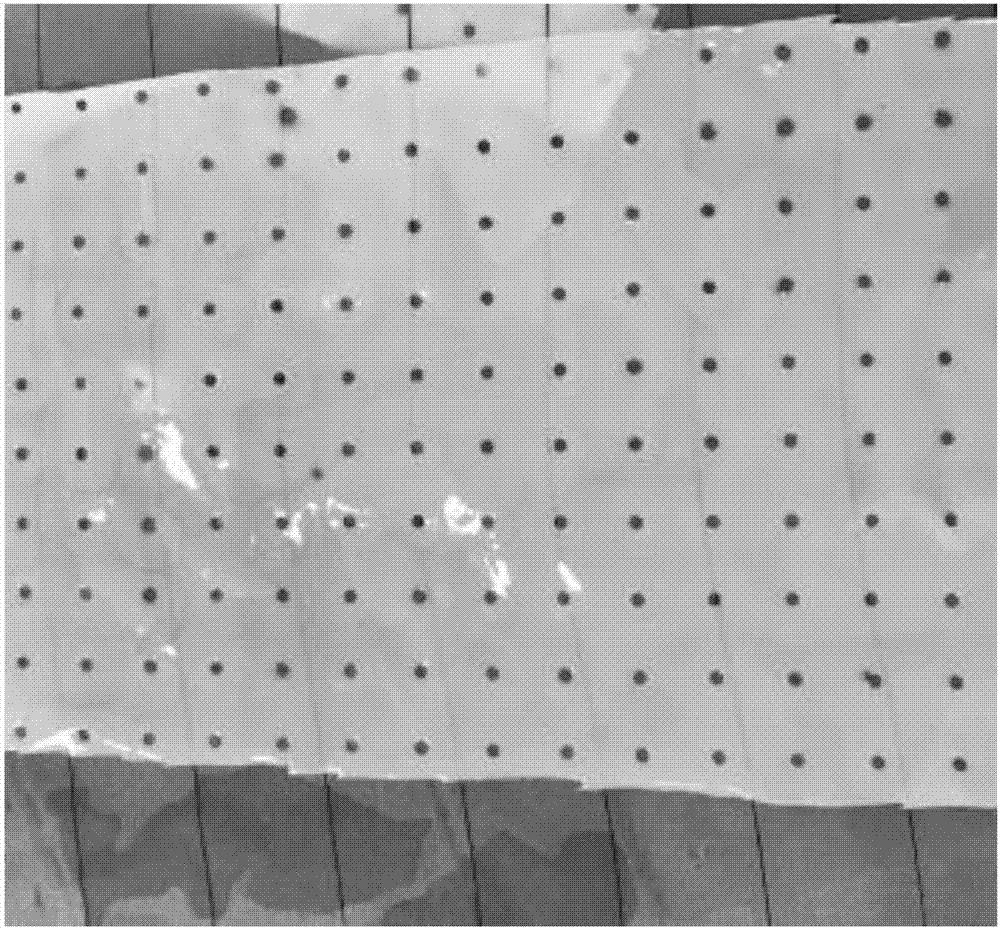

[0027] (2) The surface has holes with a diameter of 2mm and a hole density of 0.36 holes / cm 2 Clean and dry the tetrafluoroethylene plate, and keep its temperature the same as the temperature of the mixed solution. Pour the mixed solution on one end of the plate, and use a 120μm wide film scraping rod to form a uniform liquid film. After pre-evaporating for 30s , immersed in pure deionized water to obtain a primary film after 2 minutes, and wash and dry the obtained primary film to obtain a composite film for use.

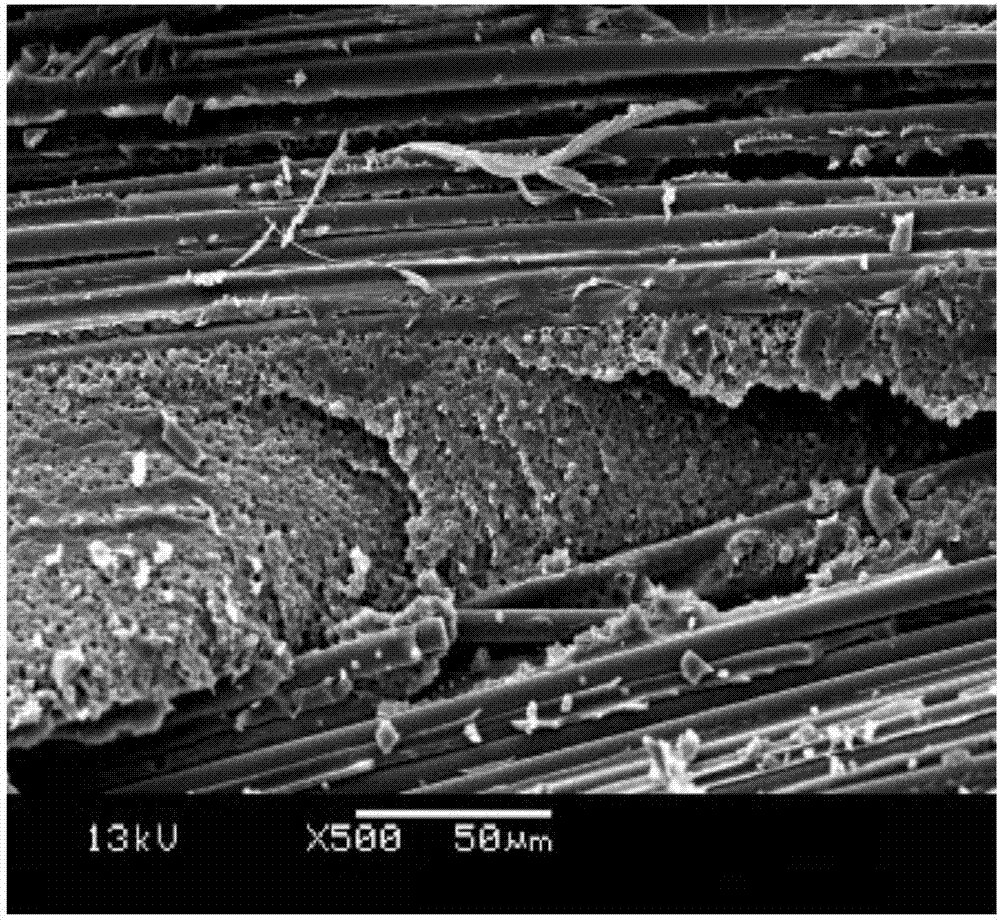

[0028] (3) Put the composite film between the continuous layers of carbon fiber cloth, lay carbon fiber cloth, release cloth, diversion net, and vacuum bag to seal the whole system according to the VARI process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com