Environment-friendly water-soluble polyvinyl alcohol packaging film and preparation method thereof

A polyvinyl alcohol and packaging film technology, applied in the field of packaging materials, can solve the problems of poor solubility, long water dissolution time, poor tensile strength, etc. The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

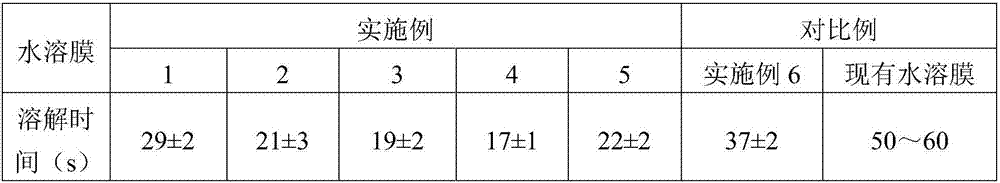

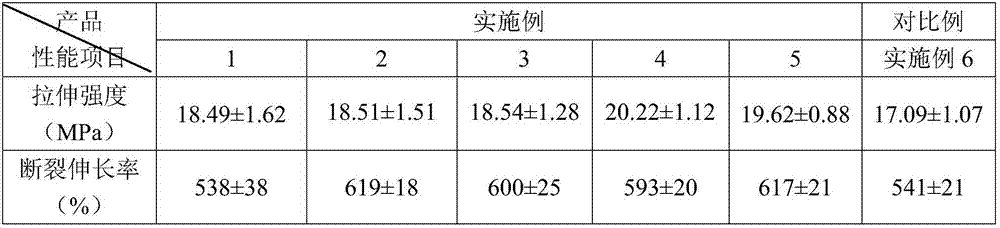

Examples

Embodiment 1

[0035] Dissolve 6 g of oxidized starch in 200 mL of distilled water, then add 6 g of glycerin / polyglycerin (mass ratio 1:1), 0.9 g of sodium lauryl ether sulfate, 0.7 g of amino silicone oil emulsion, polyvinyl alcohol resin PVA1788 (Sichuan Vinylon Plant) 24g, gelatin 1.5g, stir at 100 rpm, dissolve at 90°C for 3h to make PVA aqueous solution, maintain the temperature at 80°C, let the solution stand for defoaming for 1-2h. Then cast the solution with all bubbles removed onto a preheated stainless steel plate, place it in a blast oven at 85°C to dry for about 0.5h, take it out, cool it, peel off the film, and place it in a room with a temperature of 25°C and a relative humidity of 45%. Equilibrate at room temperature in a constant temperature and humidity box for 24 hours to obtain an environmentally friendly water-soluble polyvinyl alcohol packaging film.

Embodiment 2

[0037] Dissolve 4.8g of oxidized starch in 136mL of distilled water, then sequentially add 6g of glycerin / polyethylene glycol 200 (mass ratio 1:1), 0.9g of sodium lauryl ether sulfate, 0.7g of amino silicone oil emulsion, polyvinyl alcohol resin PVA1788 (Sichuan Vinylon Factory) 24g, gelatin 1.5g, stir at 100 rpm, dissolve at 90°C for 3h, make PVA aqueous solution, maintain the temperature at 80°C, let the solution stand for defoaming, time 1-2h . Then cast the solution with all bubbles removed onto a preheated stainless steel plate, place it in a blast oven at 85°C to dry for about 0.5h, take it out, cool it, peel off the film, and place it in a room with a temperature of 25°C and a relative humidity of 45%. Equilibrate at room temperature in a constant temperature and humidity box for 24 hours to obtain an environmentally friendly water-soluble polyvinyl alcohol packaging film.

Embodiment 3

[0039] Dissolve 6g of oxidized starch in 200mL of distilled water, then add 6g of glycerin / diethylene glycol (mass ratio 1:1), 0.9g of sodium lauryl ether sulfate, 0.7g of amino silicone oil emulsion, polyvinyl alcohol resin PVA1788 (Sichuan Vinylon Factory) 24g, gelatin 1.5g, stir at 100 rpm, dissolve at 90°C for 3h, make PVA aqueous solution, maintain the temperature at 80°C, let the solution stand for defoaming, time 1-2h . Then cast the solution with all bubbles removed onto a preheated stainless steel plate, place it in a blast oven at 85°C to dry for about 0.5h, take it out, cool it, peel off the film, and place it in a room with a temperature of 25°C and a relative humidity of 45%. Equilibrate at room temperature in a constant temperature and humidity box for 24 hours to obtain an environmentally friendly water-soluble polyvinyl alcohol packaging film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com