Coating aluminum low-temperature phosphorizing liquid

A low-temperature phosphating and coating technology, which is applied in the coating process of metal materials, can solve the problems of low corrosion resistance and wear resistance of aluminum coils, and achieve energy saving, high corrosion resistance and wear resistance, and phosphorus The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

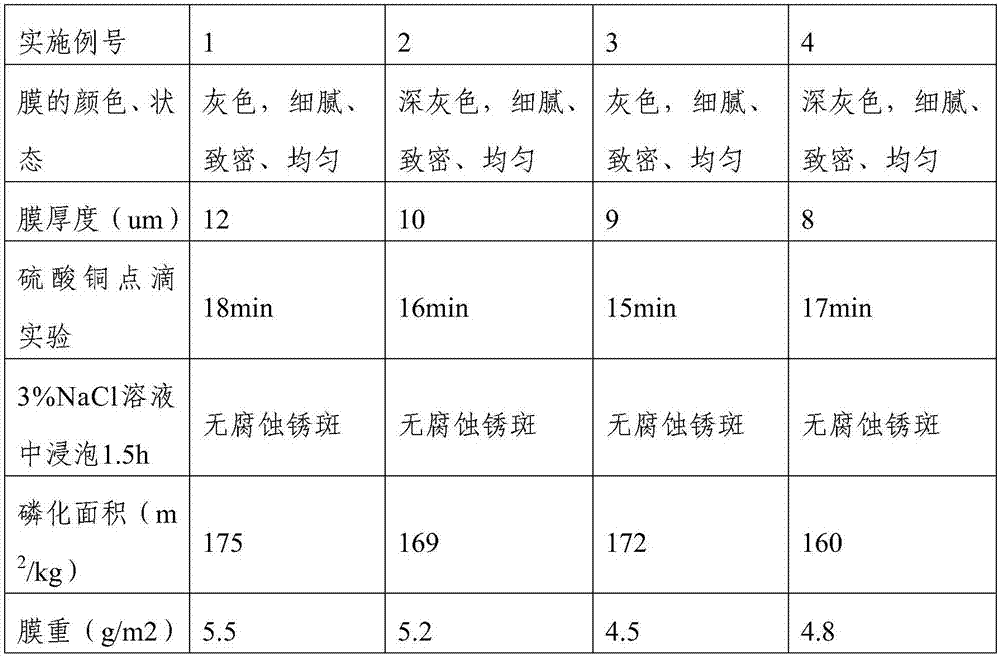

Examples

Embodiment 1

[0015] Coating aluminum low-temperature phosphating solution, including 4 parts by weight of diethylene triamine pentamethylene phosphonic acid, 1 part of phytate, 150 parts of phosphoric acid, 38 parts of zinc oxide, 40 parts of nitric acid, 3 parts of nickel nitrate and 1900 parts of water; the preparation method of the phosphating solution is: dissolve 150 parts of phosphoric acid and 40 parts of nitric acid in 1900 parts of water and stir, and leave for 12 to 24 hours; Zinc oxide, fully stirred, cooled for 9-11 hours to obtain a mixed solution of phosphoric acid and zinc oxide; after fully mixing other ingredients in the formula, add it to the aforementioned mixed solution and fully stir. Wherein the preparation process of diethylenetriamine pentamethylene phosphonic acid is as follows: 1mol of diethylenetriamine and 5mol of phosphorous acid and 100ml of 36% hydrochloric acid and 100ml of water, stir after mixing, then heat up to 80°C, drop 5mol of formaldehyde, after the ...

Embodiment 2

[0017] The difference from Example 1 is: coating aluminum low-temperature phosphating solution, including 3 parts by weight of diethylenetriaminepentamethylenephosphonic acid, 0.7 parts of phytic acid ester, 120 parts of phosphoric acid, oxidation 32 parts of zinc, 20 parts of nitric acid, 1 part of nickel nitrate and 1400 parts of water; the preparation method of the phosphating solution is: 120 parts of phosphoric acid and 20 parts of nitric acid are dissolved in 1400 parts of water and then stirred.

Embodiment 3

[0019] The difference from Example 1 is that the low-temperature phosphating solution for coating aluminum includes 6 parts by weight of diethylenetriaminepentamethylenephosphonic acid, 2 parts of phytic acid ester, 160 parts of phosphoric acid, oxidized 48 parts of zinc, 40 parts of nitric acid, 6 parts of nickel nitrate and 2000 parts of water; the preparation method of the phosphating solution is: 160 parts of phosphoric acid and 40 parts of nitric acid are dissolved in 2000 parts of water and then stirred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| film density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com