Dry preconcentration tailing discarding method for low-grade lava magnetite

A magnetite, low-grade technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of high energy consumption for grinding, increase grinding cost, and unsatisfactory separation effect, and save equipment. and civil construction investment, reducing energy consumption and steel ball consumption, and pre-selection and discarding have significant effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0038] The open-pit lava mine of the main ore body of Dahongshan Iron-copper Mine was sampled and analyzed. The results of multi-element chemical analysis are shown in Table 1, and the results of iron phase analysis in the ore samples are shown in Table 2.

[0039] Table 1 Multi-element chemical analysis results (%)

[0040]

[0041] Table 2 Analysis results of iron phase in ore samples (%)

[0042]

[0043] From the chemical analysis results of the raw ore in Table 1, it can be seen that the raw ore contains 19.08% iron, which belongs to low-grade ore, and the SiO in the ore 2 、Al 2 o 3 The content is high, and the content of harmful element S is low.

[0044]From the chemical analysis results of the raw ore in Table 2, it can be seen that the main metal mineral of the lava iron ore is magnetite, accounting for 70.94%, red limonite and siderite accounting for 15.53% in total, and the iron content in the refractory silicate reaches 12.68%.

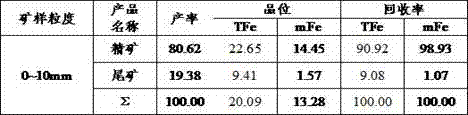

[0045] Taking ore at 910-...

Embodiment 1

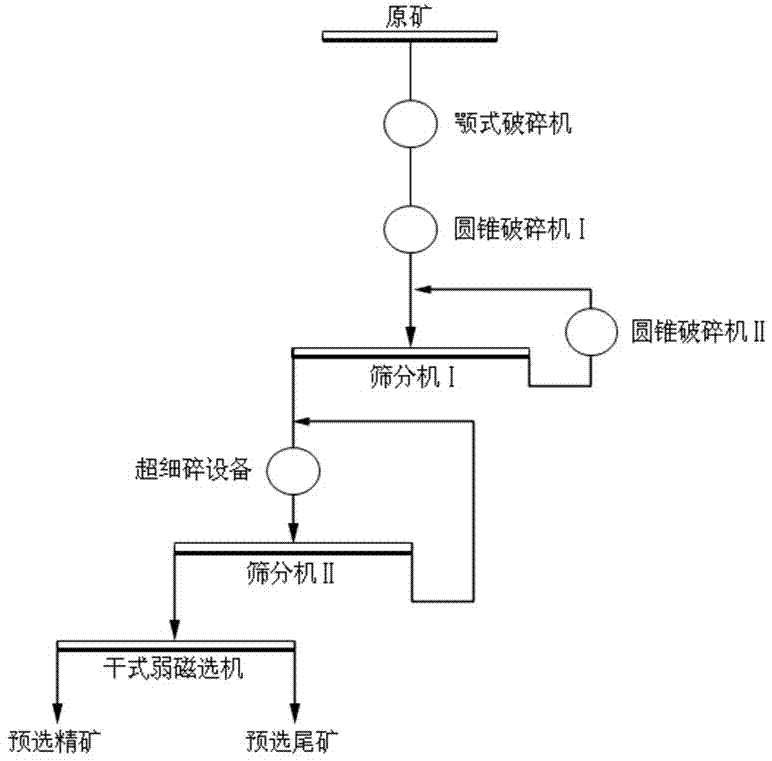

[0050] The raw ore in Table 3 of Experimental Example 1 is carried out dry pre-selection and tailings, and the steps are as follows:

[0051] S100: The raw ore above is subjected to primary crushing by a PE750×1060 jaw crusher and secondary crushing by a CF300 cone crusher in sequence to obtain secondary crushing ore particles;

[0052] S200: Sieve the above-mentioned medium crushed ore particles through 3YK-1860 circular vibrating sieve Ⅰ with amplitude 7mm, amplitude frequency 730 times / min, sieve surface inclination 26 degrees, sieve hole size 25×30, to obtain under-sieve product I and on-sieve product Product I;

[0053] S300: return the above-mentioned product I on the sieve to the circular vibrating sieve in step B after finely crushing it through the S155D cone crusher;

[0054] S400: The above-mentioned under-screen product I is further crushed by a vertical shaft impact crusher to obtain ultra-fine crushed ore particles;

[0055] S500: Sieve the above ultra-fine cru...

Embodiment 2

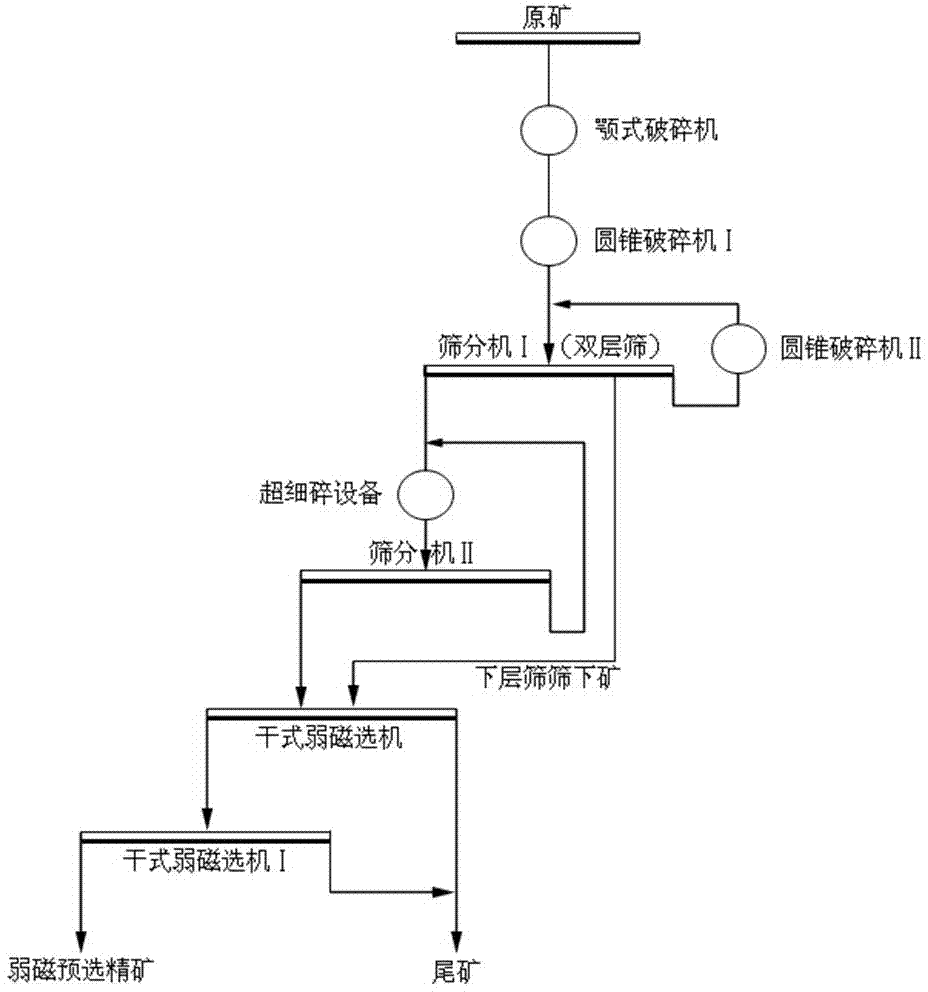

[0062] The raw ore in Table 3 of Experimental Example 1 is carried out dry pre-selection and tailings, and the steps are as follows:

[0063] S100: The raw ore above is subjected to primary crushing by a PE750×1060 jaw crusher and secondary crushing by a CF300 cone crusher in sequence to obtain secondary crushing ore particles;

[0064] S200: Sieve the above-mentioned medium crushed ore particles through a 2YA2460 vibrating sieve I with a sieve size of 20×20mm to obtain an under-sieve product I and an over-sieve product I;

[0065] S300: return the above-mentioned product I on the sieve to the circular vibrating sieve in step B after finely crushing it through the S155D cone crusher;

[0066] S400: The above-mentioned under-screen product I is further crushed by a high-pressure roller mill to obtain ultra-fine crushed ore particles;

[0067] S500: Sieve the above ultra-fine crushed ore particles through the 2YA2460 vibrating screen II with a sieve size of 7.5×10mm to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com