Manure-based fermented product and preparation method thereof

A technology of fermented products and fermented products, applied in the field of feces-based fermented products and its preparation, can solve the problems of low utilization rate of active ingredients, unsuitable for production needs, and many types of raw materials for preparation, so as to restore and improve the physical quality of soil Standards, restoration and improvement of chemical quality standards, simple effects of raw material types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A method for preparing a feces-based fermented product, comprising:

[0053] Cooking step: mixing feces, sorghum flour and corn flour in a formula amount, transporting them to a cooking pot for cooking to obtain a cooking material;

[0054] Saccharification step: take the cooking material, add saccharification enzyme, and saccharify to obtain saccharification mash;

[0055] Fermentation step: take saccharification mash, add distiller's yeast, and ferment to obtain fermented product;

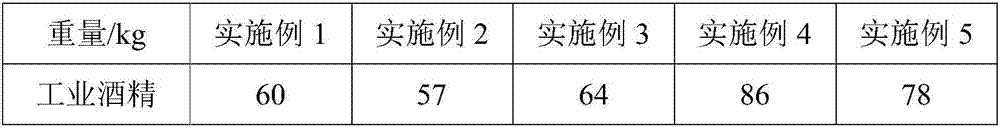

[0056] Distillation step: distilling the fermented product to obtain the distilled product and distiller's grains;

[0057] Drying step: the distiller's grains are dried to obtain the final fermented product.

[0058] As a further embodiment, it also includes a purification step: when the fermentation product is distilled, the distillation gas is collected and transported to a condensation tower, condensed into a liquid and then transported to a stripping tower for purification to obtain...

Embodiment 1-5

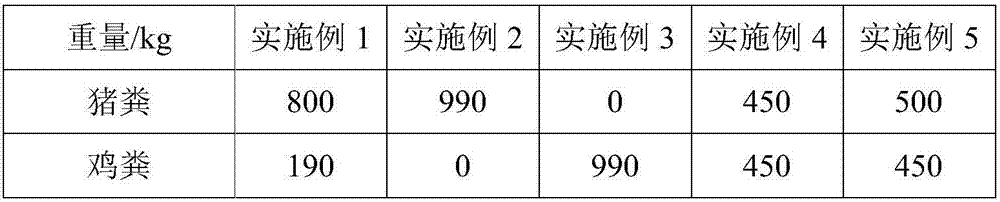

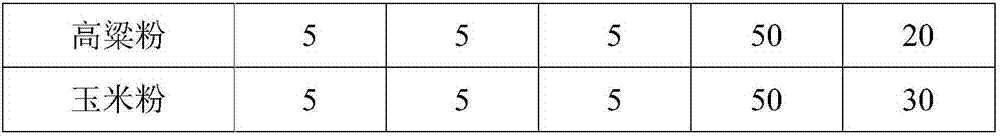

[0065] A feces-based fermented product is fermented from feces, sorghum flour and corn flour. The specific raw materials are shown in Table 1 below.

[0066] The formula table based on the fermented product of feces class of table 1 embodiment 1-5

[0067]

[0068]

[0069] A method for preparing fermented products based on feces, comprising the following steps:

[0070] Cooking steps: Mix the formula amount of pig manure, chicken manure, sorghum flour and corn flour, stir evenly, transport to the pipeline continuous digester, cook in steam at 130°C for 20min, then lower the temperature to 63°C to obtain cooked materials;

[0071] Saccharification step: take the cooking material, add glucoamylase at 1g / kg based on the cooking material, control the saccharification time to 30-60min, and obtain the saccharification mash;

[0072] Fermentation step: take the mash, add distiller's yeast (Daqu) at 2 g / kg, set the fermentation temperature to 35°C, and the fermentation time t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com