Preparation method and application of bio-based oil solidifying material

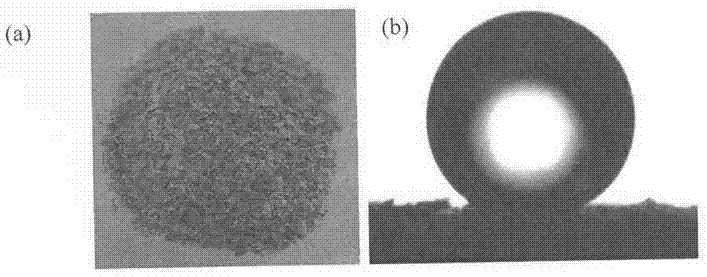

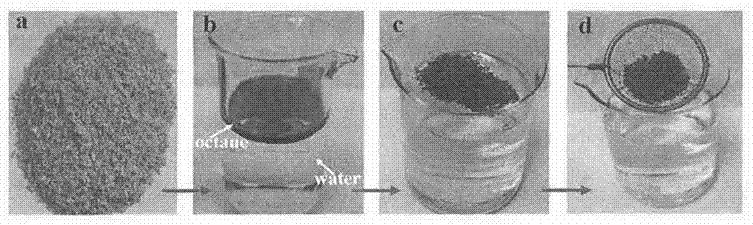

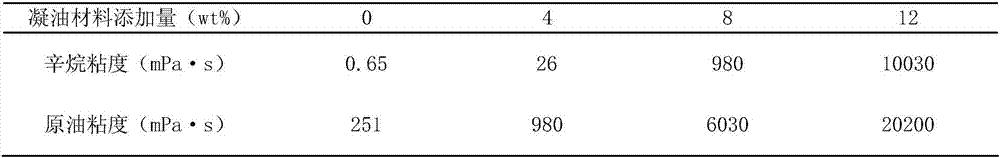

A bio-based, oil-condensing technology, which is applied in the field of preparation of bio-based oil-condensing materials, can solve problems such as difficulty in large-scale production, secondary environmental pollution, and complicated preparation process, and achieve low price, fast oil-condensing speed, and source rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] a. The wheat bran is placed in a NaOH solution with a concentration of 1 mg / mL for 5 hours to obtain pretreated wheat bran;

[0021] b, adding 0.1wt% of nano-silicon dioxide to the alkaline ethanol mixed solution containing 4wt% of vinyltrimethoxysilane coupling agent and ultrasonically for 1 hour to obtain a prefabricated mixed solution;

[0022] c, adding the pretreated wheat bran obtained in the step a to the prefabricated mixed solution obtained in the step b, stirring evenly, then pouring it into a container and sealing and then putting it into an oven for heating, the temperature is 80 ° C, and the holding time is 4 hours, to obtain Wheat bran modified with silane coupling agent;

[0023] d. Add the wheat bran modified by the silane coupling agent obtained in step c into the ethyl acetate mixed solution containing 0.05g / mL of styrene monomer and 0.05wt% azobisisobutyronitrile, stir evenly, and then transfer to In an airtight container, the reaction was carried ou...

Embodiment 2

[0028] a, placing the wheat bran in a KOH solution with a concentration of 2 mg / mL for 4 hours to obtain pretreated wheat bran;

[0029] b, adding 0.2wt% of nano titanium dioxide to the alkaline ethanol mixed solution containing 5wt% vinyltrichlorosilane coupling agent and ultrasonically for 2 hours to obtain a prefabricated mixed solution;

[0030] c, adding the pretreated wheat bran obtained in the step a to the prefabricated mixed solution obtained in the step b, stirring evenly, then pouring it into a container and sealing and then putting it into an oven for heating, the temperature is 90 ° C, and the holding time is 3 hours to obtain Wheat bran modified with silane coupling agent;

[0031] d. Add the silane coupling agent-modified wheat bran obtained in step c to the ethyl acetate mixed solution containing 0.1 mg / mL divinylbenzene and 0.1 wt% azobisisobutyronitrile, stir evenly, and then transfer to In an airtight container, the reaction is carried out at a temperature ...

Embodiment 3

[0036] a, place the wheat bran with a concentration of 3 mg / mL NaOH solution for 3 hours to obtain the pretreated wheat bran;

[0037] b, adding 0.3wt% of nano-zinc oxide to the alkaline ethanol mixed solution containing 6wt% of vinyl tri-tert-butoxysilane coupling agent and ultrasonically for 3 hours to obtain a prefabricated mixed solution;

[0038] c, adding the pretreated wheat bran obtained in the step a to the prefabricated mixed solution obtained in the step b, stirring evenly, then pouring it into a container and sealing and then putting it into an oven for heating, the temperature is 100 ° C, and the holding time is 2 hours, Obtain silane coupling agent modified wheat bran;

[0039] d. Add the silane coupling agent-modified wheat bran obtained in step b into the ethyl acetate mixed solution containing 0.13 mg / mL styrene monomer and 0.3 wt% azobisisoheptonitrile, stir evenly, and then transfer to In an airtight container, the reaction is carried out at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com