Graphene oxide antibacterial composite PVC material and preparation method thereof

A polyvinyl chloride and graphene technology, applied in the field of graphene oxide antibacterial composite polyvinyl chloride material and its preparation, can solve the problem of uneven combination of antibacterial composite and polyvinyl chloride, poor antibacterial effect, unstable properties, etc. problems, to achieve the effect of being suitable for industrial production, improving mechanical strength, and stable material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

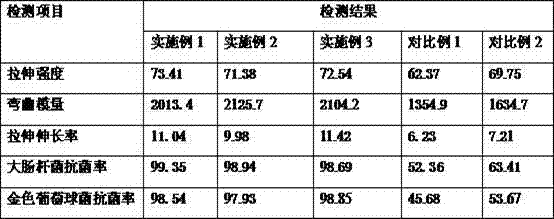

Examples

Embodiment 1

[0056] Preparation of Graphene Oxide Antibacterial Compound

[0057] (1) Take 10g of titanium dioxide with a particle size of 50-80nm and 1g of zinc oxide with a particle size of 20-50nm, pour them into the agate ball mill cylinder of the ball mill, add 11ml of water, and perform ball milling at a speed of 600rpm for 4 hours, and then divide into three batches Add 5g of nano-silver powder with a particle size of 20-50nm, then add 5ml of water, and continue ball milling for 3h. Stop ball milling, and dry at about 40-50°C under a vacuum of 0.3MPa to obtain an antibacterial mixture.

[0058] (2) Dissolve 75g of graphene oxide in 15L of ethanol, add the antibacterial mixture obtained in step (1), raise the temperature to 40~45°C, and react with ultrasonic oscillation at a frequency of 100KW for 3 hours. The graphene oxide antibacterial mixture was obtained after vacuum drying.

[0059] Preparation of graphene oxide antibacterial composite polyvinyl chloride material

[0060] We...

Embodiment 2

[0063] Preparation of Graphene Oxide Antibacterial Compound

[0064] (1) Take 10g of titanium dioxide with a particle size of 10-30nm and 0.5g of zinc oxide with a particle size of 10-30nm, pour them into the agate ball mill cylinder of the ball mill, add 10ml of water, and perform ball milling at a speed of 800rpm for 3-4 hours, then Add 3.3g of nano-silver powder with a particle size of 20-50nm in three batches, then add 3ml of water, and continue ball milling for 3h. Stop ball milling, and dry at about 40-50°C under a vacuum of 0.2MPa to obtain an antibacterial mixture.

[0065] (2) Dissolve 260g of graphene oxide in 26L of ethanol, add the antibacterial mixture obtained in step (1), raise the temperature to 40~45°C, and react with ultrasonic oscillation at a frequency of 100KW for 3 hours. The graphene oxide antibacterial mixture was obtained after vacuum drying.

[0066] Preparation of graphene oxide antibacterial composite polyvinyl chloride material

[0067] Weigh 10...

Embodiment 3

[0070] Preparation of Graphene Oxide Antibacterial Compound

[0071] (1) Take 10g of titanium dioxide with a particle size of 20-50nm and 0.7g of zinc oxide with a particle size of 20-50nm, pour them into the agate ball mill cylinder of the ball mill, add 11ml of water, and perform ball milling at a speed of 1000rpm for 4 hours, then divide into three Add 4g of nano-silver powder with a particle size of 20-50nm in batches, then add 4ml of water, and continue ball milling for 3 hours; stop the ball milling, and dry at about 40-50°C under a vacuum of 0.3MPa to obtain an antibacterial mixture.

[0072] (2) Dissolve 100g of graphene oxide in 15L of ethanol, add the antibacterial mixture obtained in step (1), raise the temperature to 40~45°C, and react with ultrasonic oscillation at a frequency of 100KW for 3 hours. The graphene oxide antibacterial mixture was obtained after vacuum drying.

[0073] Preparation of graphene oxide antibacterial composite polyvinyl chloride material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com