TiO2 giant electrorheological fluid and application thereof

A giant electrorheological fluid and solution technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of difficult practical industrial application, narrow operating temperature range, complicated preparation process, etc., and achieves low leakage current, low leakage current density, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

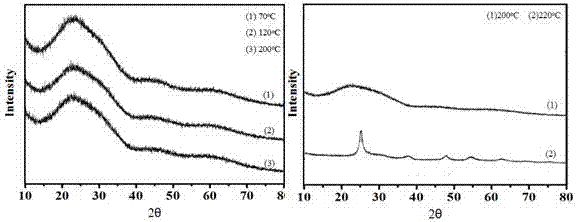

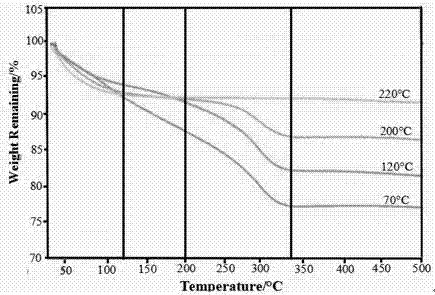

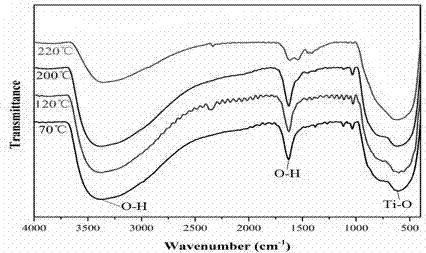

[0025] Example 1~2 TiO 2 giant electrorheological fluid

[0026] The TiO that present embodiment 1 provides 2 Giant electrorheological fluid was obtained by the following preparation method: 6 mL of deionized water was dissolved in 200 mL of absolute ethanol, and it was fully mixed under the action of a magnetic stirrer to prepare A solution; 30 mL of butyl titanate was dissolved in 300 mL of In water and ethanol, make it fully mixed under the action of a magnetic stirrer to prepare B solution; slowly drop B solution into A solution in a stirring state with a dropping funnel, fully react, and then centrifuge the generated white product, Repeated washing with deionized water and absolute ethanol, all the above operations were carried out at room temperature, and finally air-dried at 70°C for 2 hours to obtain TiO 2 particles; the TiO 2 The particles were heat-treated at 200°C for 2h to obtain a powder sample. TiO 2 Mix the powder and silicone oil in proportion to obtain Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com