Preparation method of suspended carrying track and suspended carrying track

A track and suspension technology, applied in tracks, roads, buildings, etc., can solve the problems of high cost of building and vegetation demolition, occupation of large land resources, national and social losses, etc., and achieve excellent comprehensive performance, large weight, and mechanical properties. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

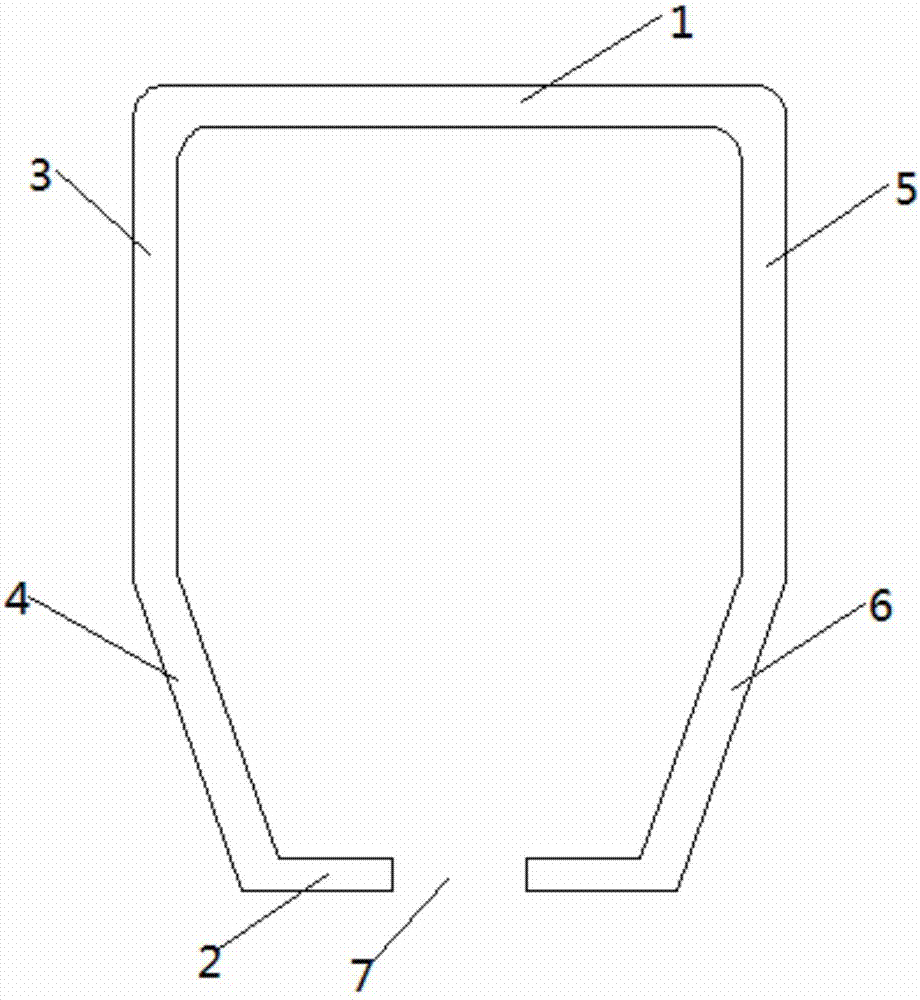

[0029] According to one aspect of the present invention, a method for preparing a suspended carrier rail is provided, comprising:

[0030] Smelting high-purity alloys as raw materials, and processing the raw materials into blanks for suspension and carrying rails;

[0031] Carry out forging and rolling on the rough material of the suspension carrying track to obtain the finished product of the suspension carrying track;

[0032] Polish the finished suspension carrying track to obtain the suspension carrying track;

[0033] Among them, the high-purity alloy contains: vanadium, chromium, boron, carbon, nickel, manganese, titanium and iron, and the composition design of the high-purity alloy is (wt%): vanadium: 0.30-0.40, chromium: 11.00-12.00, Carbon: 0.22-0.25, nickel: 1.20-1.40, manganese: 0.70-0.80, titanium: 0.0013-0.0021, silicon: 0.10-0.20, molybdenum: 0.30-0.40, and the balance is iron and unavoidable impurities.

[0034] Specifically, the purity of the suspension carri...

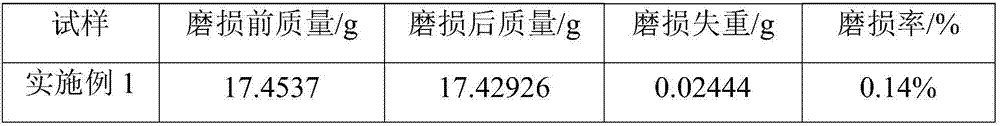

Embodiment 1

[0038] High-purity alloys are smelted in a vacuum furnace. Among them, vanadium, chromium, carbon, nickel, manganese, titanium, silicon, molybdenum and iron are designed as high-purity alloys (wt%): vanadium: 0.30, chromium: 11.00, Carbon: 0.22, nickel: 1.40, manganese: 0.70, titanium: 0.0013, silicon: 0.20, molybdenum: 0.30, and the balance is iron and unavoidable impurities.

[0039] Smelting high-purity alloys as raw materials, and processing the raw materials into blanks for suspension and carrying rails;

[0040] Carry out forging and rolling on the rough material of the suspension carrying track to obtain the finished product of the suspension carrying track;

[0041] Polish the finished suspension carrying track to obtain the suspension carrying track.

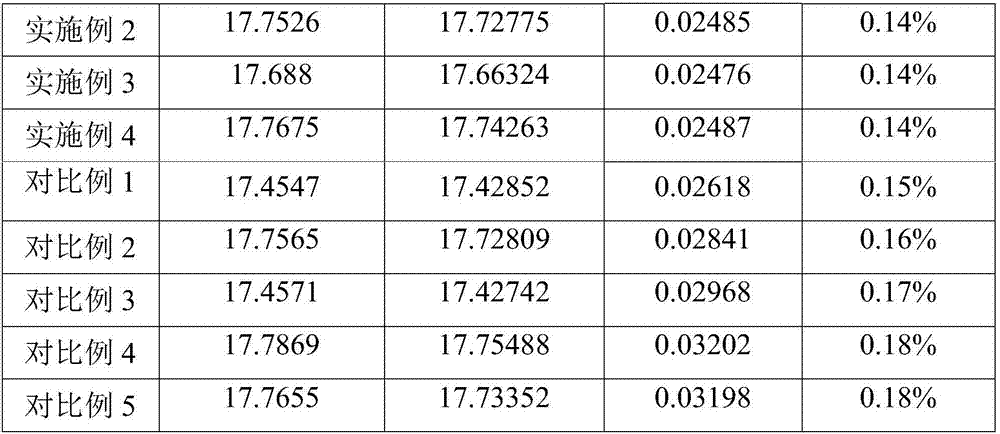

Embodiment 2

[0043] High-purity alloys are smelted in a vacuum furnace. Among them, vanadium, chromium, carbon, nickel, manganese, titanium, silicon, molybdenum and iron are designed as high-purity alloys (wt%): vanadium: 0.40, chromium: 12.00, Carbon: 0.25, nickel: 1.20, manganese: 0.80, titanium: 0.0021, silicon: 0.10, molybdenum: 0.40, and the balance is iron and unavoidable impurities.

[0044] Smelting high-purity alloys as raw materials, and processing the raw materials into blanks for suspension and carrying rails;

[0045] Carry out forging and rolling on the rough material of the suspension carrying track to obtain the finished product of the suspension carrying track;

[0046] Polish the finished suspension carrying track to obtain the suspension carrying track.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com