Composite board and manufacturing method thereof

A manufacturing method and technology for composite panels, applied in building components, thermal insulation and other directions, can solve the problems of reducing thermal insulation, thermal insulation performance, hidden dangers of wall structure safety, unreasonable structural design, etc., and achieve high environmental protection, low pollution, fiber slender effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

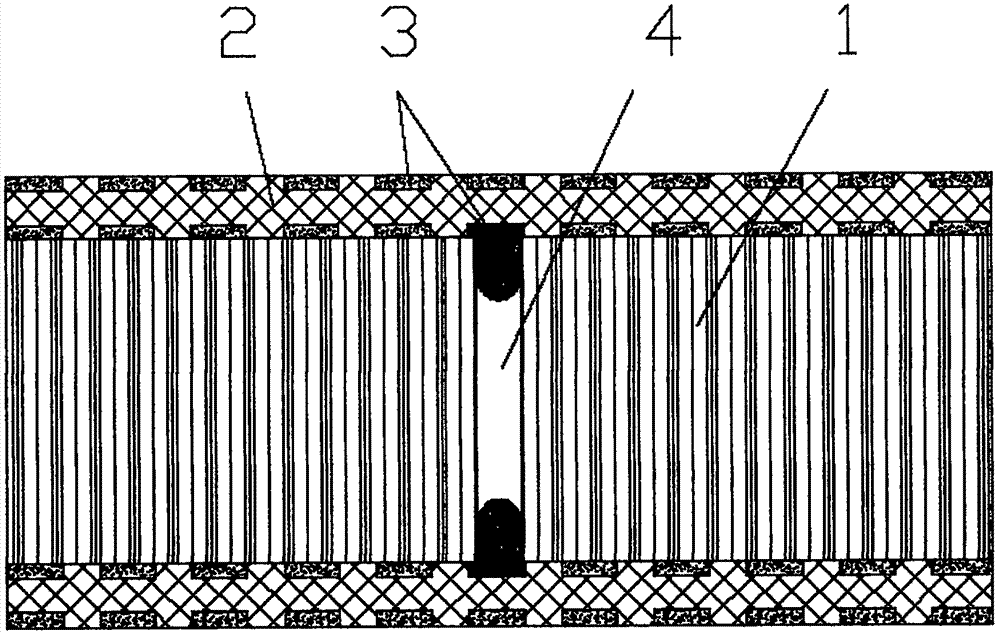

[0028] A composite board, comprising a rock wool board 1 and a glass fiber mesh cloth 2, the rock wool board 1 has several pieces and each rock wool board 1 is assembled from several schist rock wool strips, the glass fiber mesh cloth 2 Cover the upper and lower sides of the rock wool board 1 and bond it to the rock wool board 1 through the slurry coating 3, the rock wool strip is perpendicular to the plane where the glass fiber mesh cloth 2 is located, and the adjacent rock wool board There is a gap 4 of 9 mm between 1 and the thickness of the rock wool board 1 is 9 cm;

[0029] The slurry coating 3 includes cement, quartz sand, polymer latex powder, water retaining agent, accelerator and water, and the thickness of the slurry coating 3 is specifically 8 mm.

[0030] In the present embodiment, in the slurry coating 3, the mass ratio of the cement, quartz sand and water is cement: quartz sand: water=1:1:1, and the polymer latex powder, water retaining agent and The total mass...

Embodiment 2

[0038] A composite board, comprising a rock wool board 1 and a glass fiber mesh cloth 2, the rock wool board 1 has several pieces and each rock wool board 1 is assembled from several schist rock wool strips, the glass fiber mesh cloth 2 Cover the upper and lower sides of the rock wool board 1 and bond it to the rock wool board 1 through the slurry coating 3, the rock wool strip is perpendicular to the plane where the glass fiber mesh cloth 2 is located, and the adjacent rock wool board There is a gap 4 of 10mm between 1 and the thickness of the rock wool board 1 is specifically 10cm;

[0039] The slurry coating 3 includes cement, quartz sand, polymer latex powder, water retaining agent, accelerator and water, and the thickness of the slurry coating 3 is specifically 9mm.

[0040] In the present embodiment, in the slurry coating 3, the mass ratio of the cement, quartz sand and water is cement: quartz sand: water=1:1:1, and the polymer latex powder, water retaining agent and Th...

Embodiment 3

[0048] A composite board, comprising a rock wool board 1 and a glass fiber mesh cloth 2, the rock wool board 1 has several pieces and each rock wool board 1 is assembled from several schist rock wool strips, the glass fiber mesh cloth 2 Cover the upper and lower sides of the rock wool board 1 and bond it to the rock wool board 1 through the slurry coating 3, the rock wool strip is perpendicular to the plane where the glass fiber mesh cloth 2 is located, and the adjacent rock wool board There is a gap 4 of 11 mm between 1 and the thickness of the rock wool board 1 is 11 cm;

[0049]The slurry coating 3 includes cement, quartz sand, polymer latex powder, water retaining agent, accelerator and water, and the thickness of the slurry coating 3 is specifically 10mm.

[0050] In the present embodiment, in the slurry coating 3, the mass ratio of the cement, quartz sand and water is cement: quartz sand: water=1:1:1, and the polymer latex powder, water retaining agent and The total mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com