Waste incineration purification system

A purification system and waste incineration technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of dust, waste water and waste gas leakage, large equipment occupation, secondary pollution, etc., and achieve a high degree of harmlessness and occupy The effect of small area and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

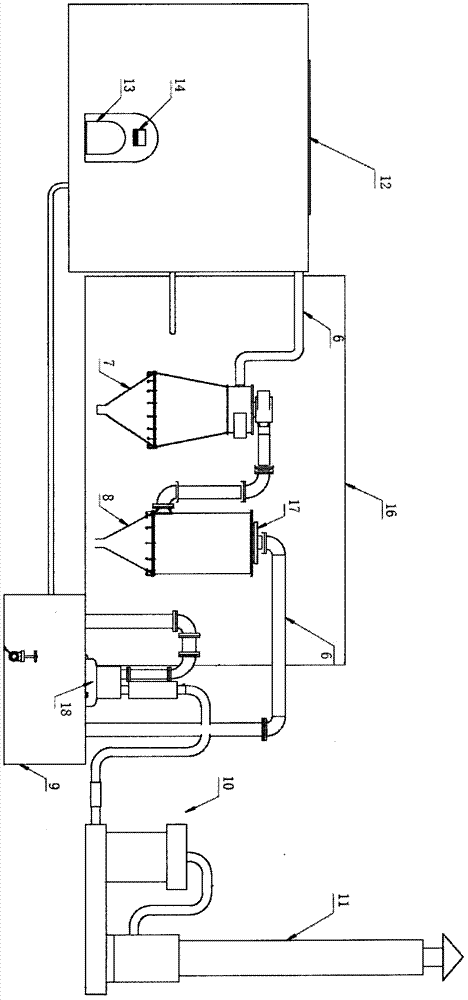

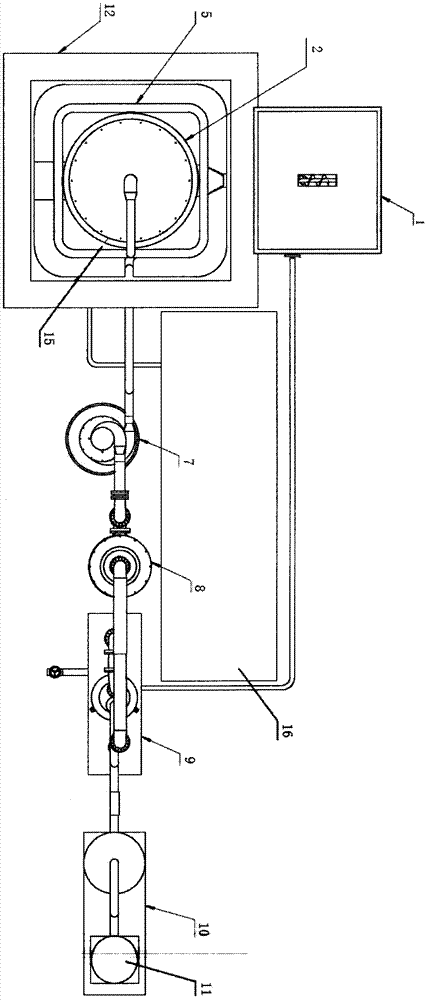

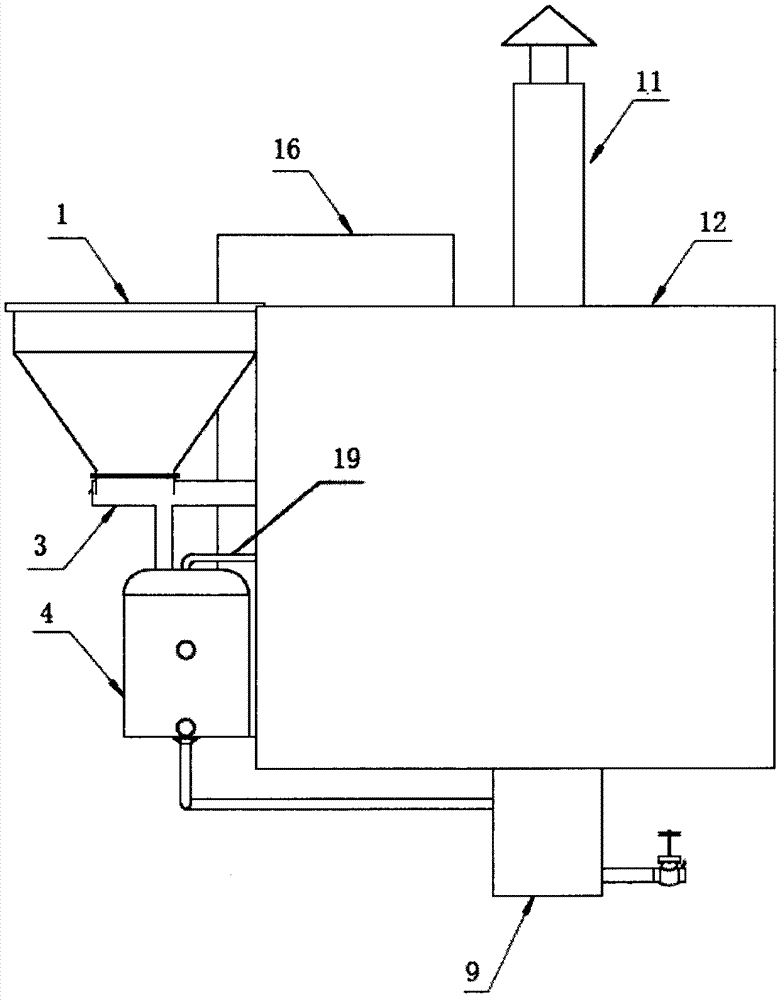

[0013] Such as Figure 1-3 As shown, the present invention comprises a hopper 1 and an incinerator 2, and the hopper 1 is connected to the biogas digester 4 and the incinerator 2 respectively through a conveying pipeline 3; the upper end of the incinerator 2 is provided with a waste gas water cooling pipe 5, and the waste gas water cooling pipe 5 passes through the conveying pipe 6 is in turn connected with the spiral dust collection tank 7, dust collection tank 8, disinfection sedimentation tank 9, gas purification and drying system 10, and gas discharge tower 11; the incinerator 2 is sealed by a concrete wall 12, and one side of the concrete wall 12 is provided with Air intake, ash outlet 13, and observation port 14; the waste gas water cooling pipe 5 is fixed in the overall heat insulation cavity 15 of the incinerator 2, and the heat insulation cavity 15 is directly connected with the cold water pool 16; the top of the spiral dust collection tank 7 Sprayer 17 is provided; P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com