Deep defluorination system and method for electroplating wastewater

A technology of electroplating wastewater and fluorine system, which is applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of difficult discharge of fluoride, increase the cost of wastewater treatment, and high fluoride ion concentration, and improve the treatment efficiency. and social and economic benefits, improve the efficiency of fluoride removal, and reduce the effect of fluoride content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

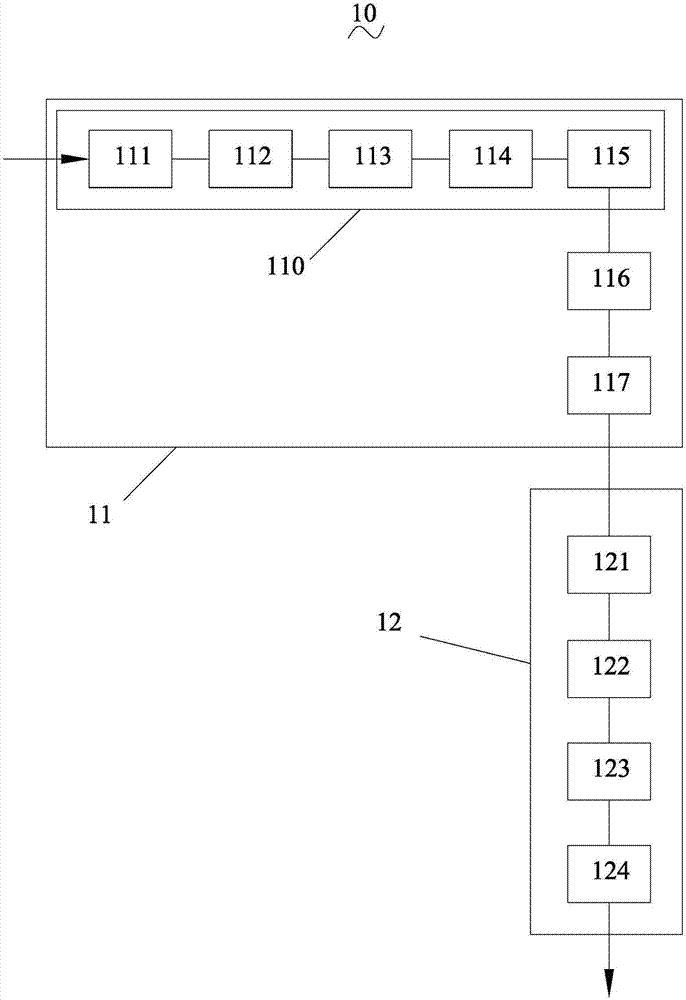

Image

Examples

Embodiment 1

[0062] The adsorption sedimentation tank 121 uses activated alumina and activated carbon as adsorbents;

[0063] The process parameters of the primary sedimentation tank 122 are as follows: add polyacrylamide aqueous solution, and the mass ratio of polyacrylamide to water is 2:1000;

[0064] The process parameters of the inorganic aluminum salt reaction tank 123 are: the inorganic aluminum salt used is aluminum sulfate, the dosage of aluminum sulfate is 1.0g / L waste water, and the reaction time is 30 minutes;

[0065] The technological parameters of the secondary sedimentation tank 124 are as follows: add polyacrylamide aqueous solution, and the mass ratio of polyacrylamide to water is 2:1000.

[0066] other same figure 1 As shown in the schematic diagram, the comparison of data before and after treatment is shown in Table 1.

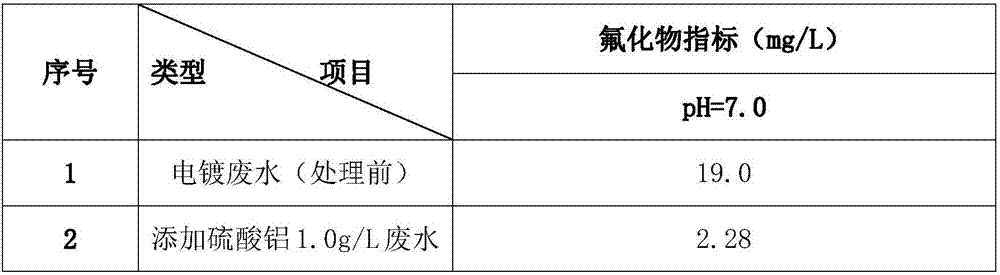

[0067] Table 1. Data before and after deep defluorination of electroplating wastewater (dosing amount of aluminum sulfate: 1.0g / L wastewater)

[006...

Embodiment 2

[0071] The adsorption sedimentation tank 121 uses activated alumina and activated carbon as adsorbents;

[0072] The process parameters of the primary sedimentation tank 122 are as follows: add polyacrylamide aqueous solution, and the mass ratio of polyacrylamide to water is 2:1000;

[0073] The process parameters of the inorganic aluminum salt reaction tank 123 are: the inorganic aluminum salt used is aluminum sulfate, the dosage of aluminum sulfate is 1.5g / L waste water, and the reaction time is 30 minutes;

[0074] The technological parameters of the secondary sedimentation tank 124 are as follows: add polyacrylamide aqueous solution, and the mass ratio of polyacrylamide to water is 2:1000.

[0075] other same figure 1 As shown in the schematic diagram, the comparison of data before and after treatment is shown in Table 2.

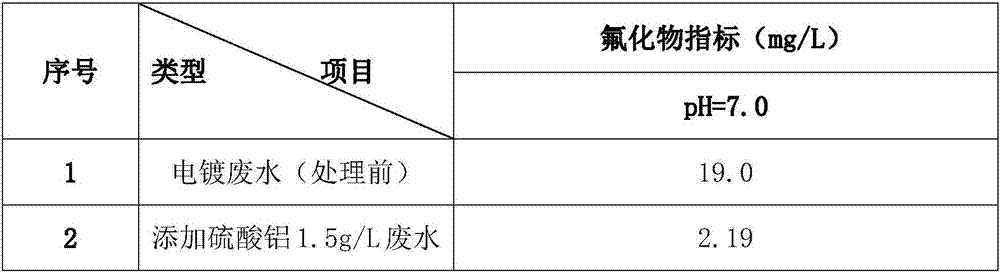

[0076] Table 2. Data before and after deep defluorination of electroplating wastewater (dosing amount of aluminum sulfate: 1.5g / L wastewater)

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com