Ultrasonic wave and microwave assisted pass-type metal salt tanning method

A microwave-assisted, metal salt technology, applied in the field of leather processing, can solve the problems of inability to achieve zero-chromium emission from chrome tanning, and achieve the effects of high viscosity, small changes in composition and properties, and strong acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

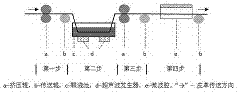

Method used

Image

Examples

Embodiment 1

[0034] For the pickling bare hide with a thickness of 0.8mm, first use sodium carbonate to adjust the pH value of the pickling bare hide to 4.5, and then use a roller extruder to adjust the distance between the extrusion rollers to 60% of the initial thickness of the bare hide. ; Pass the extruded bare leather with the grain side down through the aluminum sulfate tanning solution, which contains 50g / L sodium chloride and 70g / L aluminum oxide, tanning for 10min under the action of 40KHz ultrasonic waves, and then tanning on the extrusion roller Mechanical extrusion is carried out under the condition that the distance between them is 40% of the initial thickness of the bare hide; repeated tanning in the above-mentioned aluminum sulfate tanning solution once, and no mechanical extrusion is carried out after the first repeated tanning; finally, after the tanning agent has penetrated The aluminum tanning operation is completed by heat-preserving the leather base under 30°C microwave...

Embodiment 2

[0036] For the pickling bare hide with a thickness of 0.9mm, first use sodium bicarbonate and sodium formate to adjust the pH value of the pickling bare hide to 3.5, and then use a roller extruder to adjust the distance between the extrusion rollers to 40% of the initial thickness of the bare hide Extruding; pass the extruded bare leather with the grain side down through zirconium sulfate tanning solution, which contains 60g / L sodium chloride and 60g / L zirconium dioxide, tanning for 5min under the action of 40KHz ultrasonic waves, and then extruding Mechanical extrusion is carried out under the condition that the distance between the pressing rollers is 60% of the initial thickness of the bare hide; repeated tanning in the above-mentioned zirconium sulfate tanning solution for 3 times, and no mechanical extrusion is carried out after the third repeated tanning; finally, the tanning will be completed Zirconium tanning is completed by irradiating microwaves at 40°C for 10 minutes...

Embodiment 3

[0038] For the pickling bare hide with a thickness of 1.5mm, first use sodium bicarbonate to adjust the pH value of the pickling bare hide to 5.0, and then use a roller extruder to adjust the distance between the extrusion rollers to 55% of the initial thickness of the bare hide. Pressing; put the extruded bare leather grain face down into chrome sulfate tanning solution, which contains 60g / L sodium chloride and 50g / L chromium trioxide, tanning for 3min under the action of 40KHz ultrasonic waves, and then extruding Mechanical extrusion is carried out under the condition that the distance between the pressing rollers is 50% of the initial thickness of the bare hide; repeated tanning in the above-mentioned chromium sulfate tanning solution once, and no mechanical extrusion is carried out after the first repeated tanning; finally, the tanning will be completed After the agent has penetrated, the leather base is placed under microwave irradiation at 40°C for 5 minutes, and the chro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com